- FDM 3D Printed Pallet Jack Forklift Toy Functional Model

- DLP 3D Printed Ceramic Board with Schwarz D Pattern Infill Patterns

Material Resin

Quantity 140 pcs

Price Range $100-1,000

Lead Time 10 workdays

Gallery

About Project

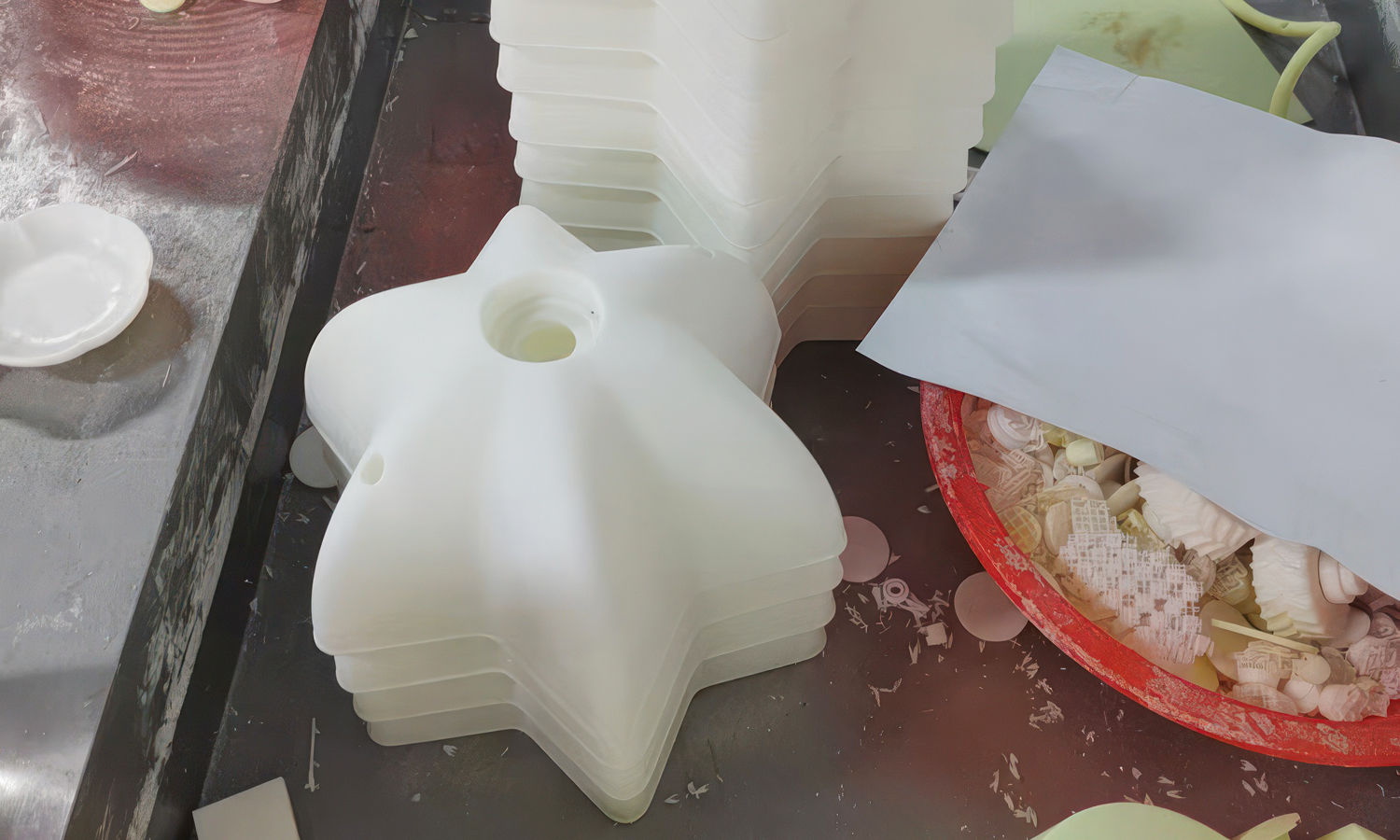

These captivating floral wall decorations, meticulously crafted using SLA 3D printing with resin, bring a touch of nature’s elegance to any space. The design features a captivating arrangement of 140 flowers, half boasting six delicate petals and the other half with five. Visually, they resemble large, open bowls shaped like blossoms, artfully piled together.

But beneath their beauty lies a functional marvel. The backs of these flowers incorporate a network of reinforcing ribs, intricately interconnected to provide exceptional support across the entire surface. This ingenious design distributes stress evenly, significantly enhancing the overall strength of each piece. The ribs themselves boast a strategic depth and thickness, ensuring they effectively support the structure without adding unnecessary weight.

For added functionality, the center of each flower’s back features a unique extruding element. This element likely serves a dual purpose: acting as a convenient mounting point and a connector for easy assembly. The surrounding network of ribs further bolsters the extrusion’s stability, creating a robust and reliable connection point.

Bring your vision to life with FacFox’s expert 3D printing services!

FacFox is a leading provider of high-quality 3D printing solutions, specializing in SLA printing with resin. Our team of experts possesses the knowledge and skill to translate your designs into stunning, functional realities, just like these remarkable floral wall decorations. If you’re looking to elevate your space with unique and captivating 3D-printed creations, FacFox is here to help. Contact us today to discuss your project and discover how we can turn your vision into a reality.

Solution

- Step 1: Design Creation. The designs for the flowers were created using CAD software. Two versions were made, one with six petals and one with five petals.

- Step 2: File Preparation. The CAD files were prepared for 3D printing by converting them into STL format. The files were then sliced into layers using slicing software.

- Step 3: Printer Setup. The SLA 3D printer was set up, and the resin tank was filled with the appropriate resin material. SLA Generic Resin and SLA Tough Resin were chosen for their good stiffness and impact resistance.

- Step 4: Printing Process. The sliced files were uploaded to the printer, and the printing process was initiated. Each flower was printed layer by layer, with the reinforcing ribs and central extrusion being formed as part of the design.

- Step 5: Post-Processing. Once the printing was completed, the flowers were removed from the build platform. Excess resin was cleaned off using isopropyl alcohol.

- Step 6: Curing. The printed flowers were placed in a UV curing chamber to fully cure the resin and ensure the structural integrity of the objects.

- Step 7: Inspection. Each flower was inspected for any defects or imperfections. The reinforcing ribs and central extrusion were checked for proper formation and strength.

- Step 8: Finishing. Any necessary finishing touches, such as sanding or painting, were applied to the flowers to achieve the desired appearance.

- Step 9: Packaging. The finished flowers were carefully packaged to prevent damage during transportation. The 140 pieces, consisting of both six-petal and five-petal versions, were prepared for delivery to the client.