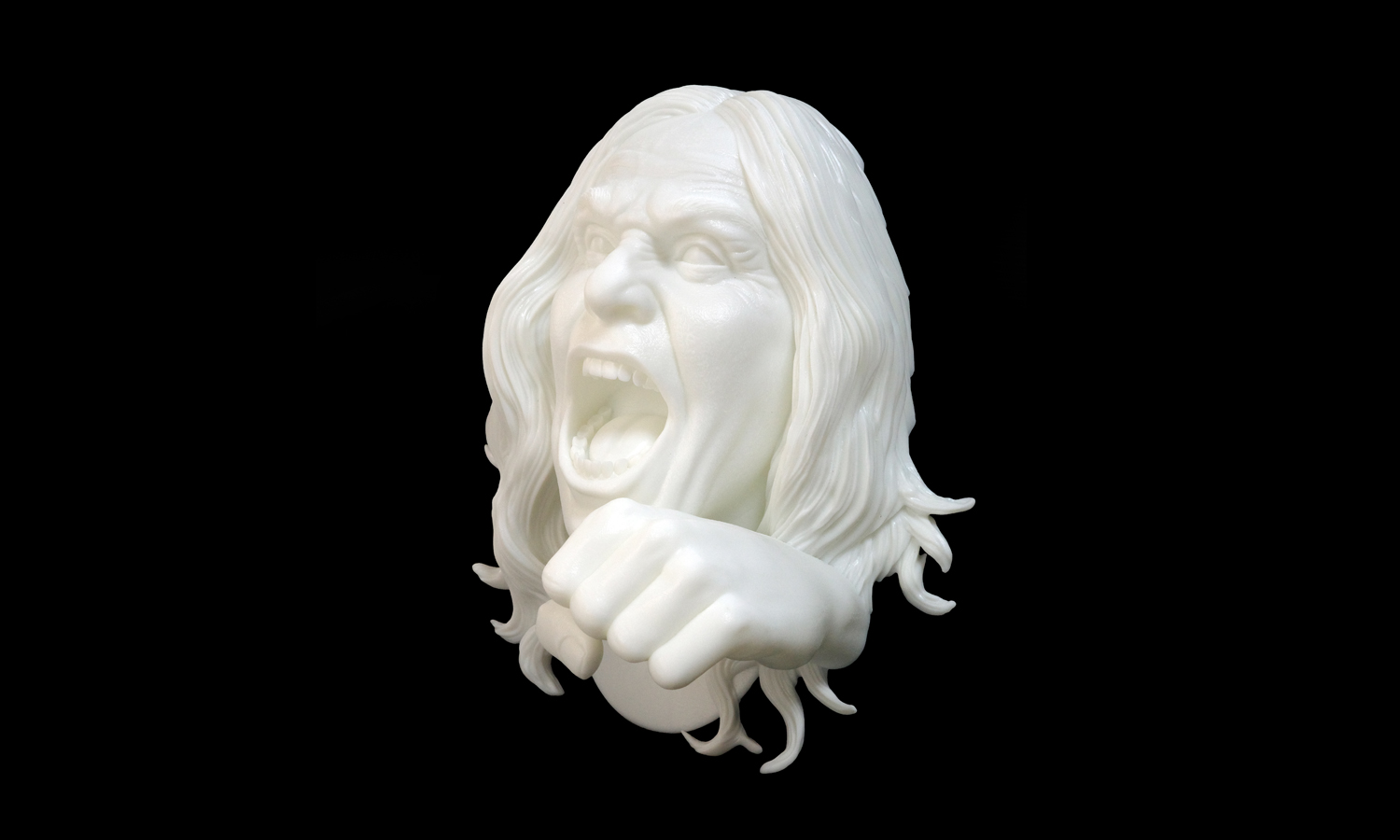

- SLA 3D Printed Full-Scale Scream Frame Resin Sculpture

- Castable Wax and Silver Prototypes of Commemorative Diorama Ring

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

This emotionally charged sculpture captures a human figure frozen in a scream – eyes wide, mouth open, fist raised. Every fold, wrinkle, and strand of hair is sculpted with intensity, conveying both rage and vitality. The model’s dramatic anatomy and flowing locks make it a striking test of precision for any 3D printing process.

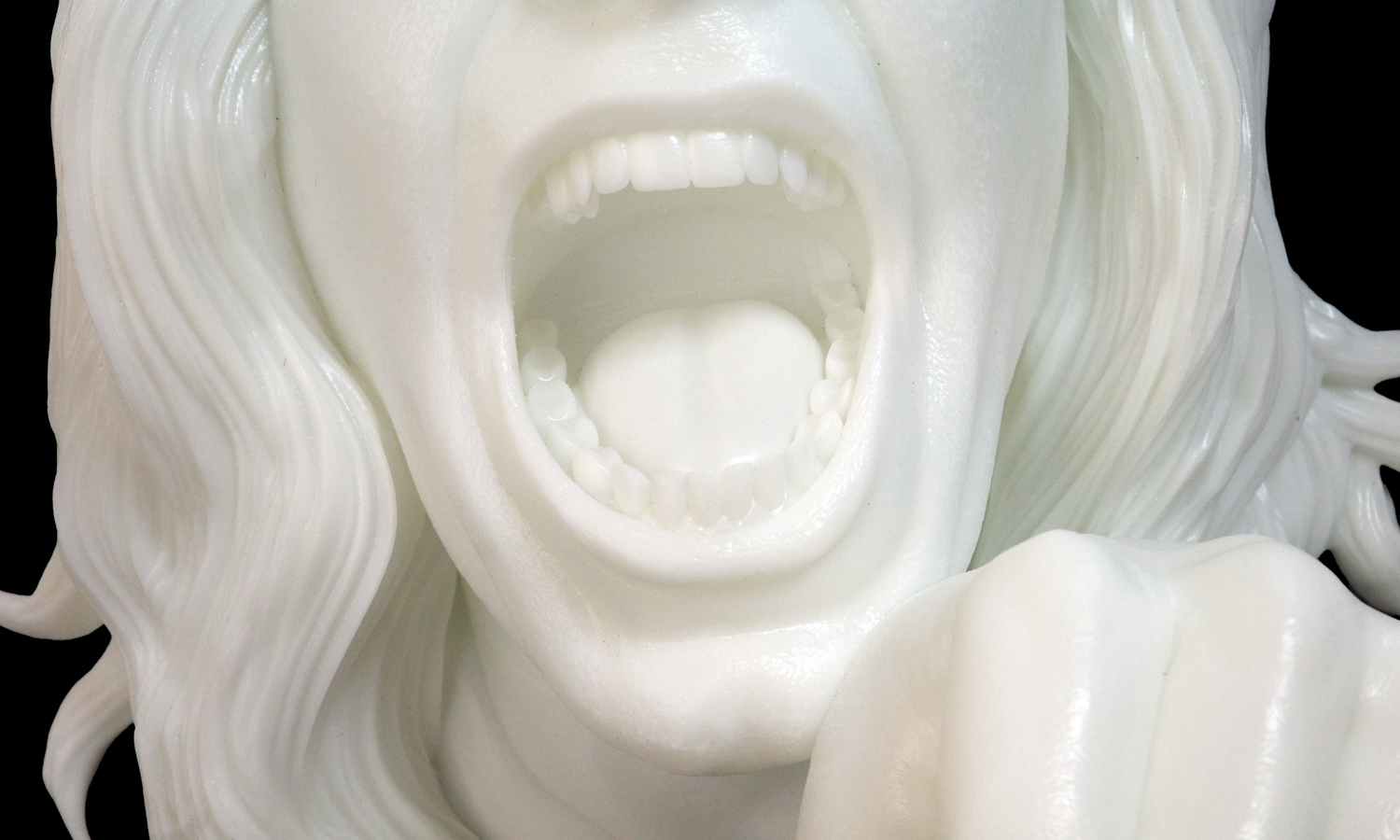

Printed using SLA (Stereolithography) technology with high-detail resin, the result is remarkably smooth and consistent. Even under close inspection, as seen in the macro shot of the face, the fine wrinkles, pores, and subtle transitions of skin are rendered cleanly with minimal visible layer texture. The translucent white resin gives the sculpture a marble-like appearance, enhancing the emotional depth and giving it the aura of a traditional carved bust.

The surface finish demonstrates excellent light reflection and tonal softness, typical of premium resin materials. There’s no sign of print lines on the curved forehead or nose bridge – evidence of careful layer calibration and proper post-curing. Despite the challenging overhangs of the hair and clenched hand, there are no visible support scars or distortions, showcasing the precision and craftsmanship behind the print setup.

Bring Your Vision to Life with FacFox

FacFox’s SLA 3D printing service empowers artists, designers, and engineers to transform intricate digital sculptures into gallery-ready pieces. With a wide selection of resin materials – from translucent and flexible to engineering-grade – and micron-level accuracy, FacFox delivers smooth surfaces and flawless detail reproduction. Whether you’re developing fine art, prototypes, or collectibles, FacFox ensures your 3D print embodies the full expression of your creativity.

Solution

- Step 1: The 3D model was inspected, repaired for mesh errors, and confirmed to be watertight.

- Step 2: The bust was scaled to full size and hollowed with proper wall thickness and drainage holes.

- Step 3: The model was oriented to minimize supports on visible areas and ensure structural balance.

- Step 4: Supports were generated with light touchpoints on the face and stronger bases under the collar.

- Step 5: The file was sliced at 50-100 ╬╝m layer height and printed in translucent white resin using SLA technology.

- Step 6: After printing, excess resin was rinsed off and the model was UV post-cured to full hardness.

- Step 7: Supports were removed, surfaces were lightly sanded and polished to achieve a smooth finish.

- Step 8: The final piece was cleaned, inspected for accuracy and surface quality, then safely packaged for delivery.