- SLA 3D Printed Clear Resin Hollowed Human Skull Model

- [Service Alert] Team trip to Thailand till June.23, support replies will be delayed. Production and shipping remain normal.

Gallery

About Project

Looking for a unique and impressive trophy to honor your competition’s MVP? Look no further than this stunning SLA 3D-printed cylinder trophy with a CNC aluminum base!

A Striking Presentation

This award features a sleek, modern design with a crisp white body and a sturdy grey aluminum base. The trophy rests elegantly on a black surface, creating a visually striking presentation.

The Star of the Show: Bold Lettering and Subtle Accents

The highlight of the piece is the bold, capitalized inscription “MAN OF THE MATCH” prominently displayed on the front. Four horizontal black stripes add a touch of detail and complement the text.

More Than Just Looks: Celebrating Achievement

This trophy isn’t just about aesthetics; it’s about recognizing exceptional achievement. Traditionally awarded to the standout performer in a sports match, it symbolizes the competitor’s superior skills and significant contribution to the game. It’s a meaningful item that celebrates individual accomplishment and will be a cherished reminder of victory for years to come.

Personalize Your Champions’ Trophies

Want to personalize your trophies and create something truly special? FacFox offers a wide range of 3D printing and CNC machining services to bring your trophy ideas to life. Our experienced team can help you design, customize, and produce trophies that perfectly reflect your brand and event.

Contact FacFox today and let us help you create trophies that celebrate your champions!

Solution

- Step 1: 3D Modeling.┬ĀFirst, a 3D model of the trophy was meticulously designed. This digital blueprint included the cylindrical body, the inscription “MAN OF THE MATCH” in bold capital letters, four horizontal stripes positioned below the text, and three tapping holes precisely placed at the bottom of the cylinder.

- Step 2: SLA 3D Printing. The trophy’s body was then produced using a method called Stereolithography (SLA) 3D printing. In this process, a liquid resin was cured layer-by-layer with a laser beam, solidifying into the desired white trophy shape according to the pre-designed 3D model.

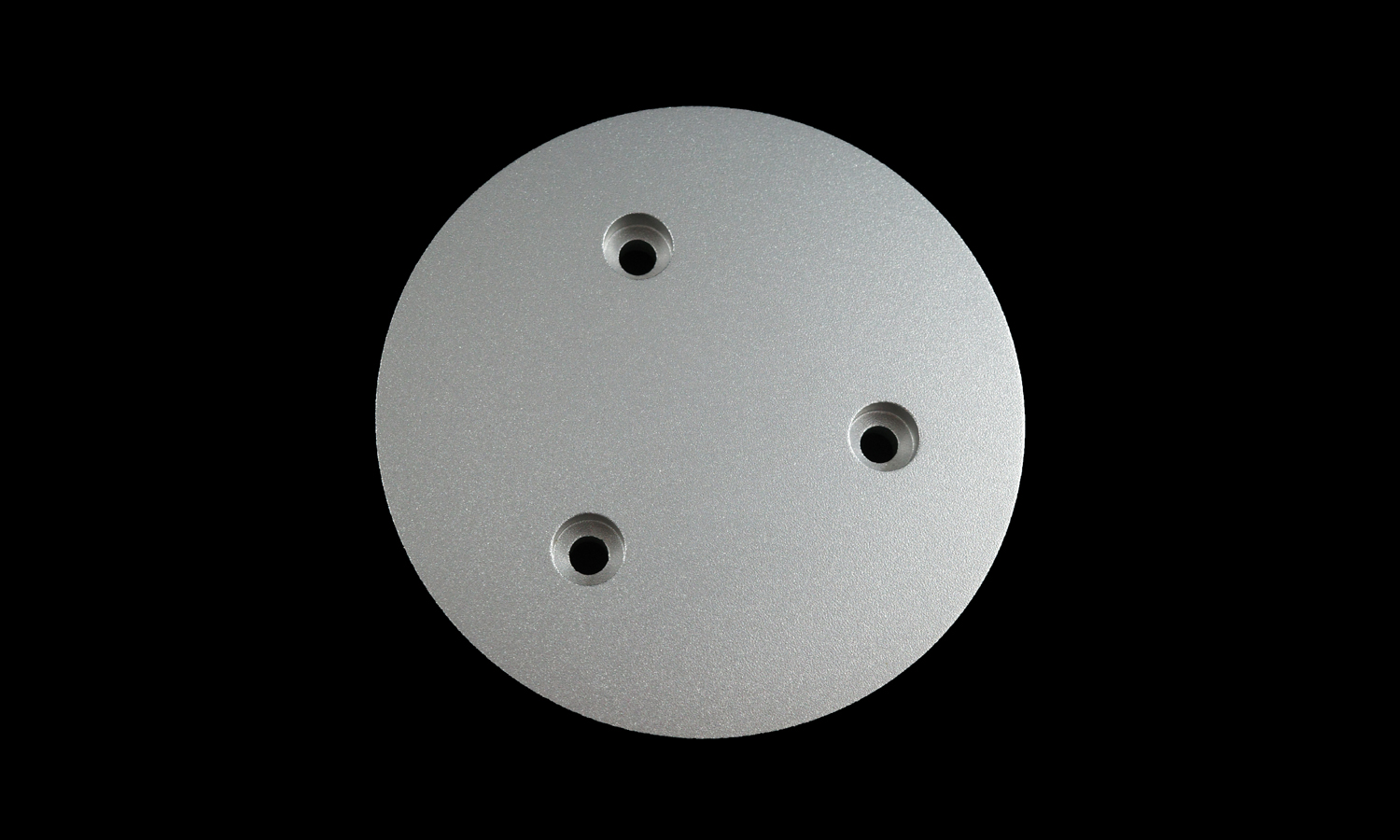

- Step 3: CNC Machining. The trophy’s base was crafted from a solid block of aluminum using Computer Numerical Control (CNC) machining. A CNC machine precisely removed material from the aluminum block based on the digital instructions of the 3D model, resulting in the final grey trophy base.

- Step 4: Tapping. After the aluminum base was machined, three tapping holes were created on its underside to match the holes in the 3D-printed body. These holes would allow for threaded fasteners to securely connect the two components.

- Step 5: Finishing Touches. Once both the 3D-printed body and CNC-machined base were complete, they likely underwent a finishing process to ensure a smooth surface and a polished appearance. The cylinder was sprayed with a thin layer of glossy white paint and brushed with black stripes.

- Step 6: Assembly: Finally, the 3D-printed trophy body was securely fastened to the CNC-machined aluminum base using threaded inserts or screws installed in the tapped holes. This completed the custom trophy, ready for presentation.