- Transparent SLA 3D Printed Flow Channel Models for Visualization

- SLA 3D Printed Full-Scale Scream Frame Resin Sculpture

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 8 workdays

Gallery

About Project

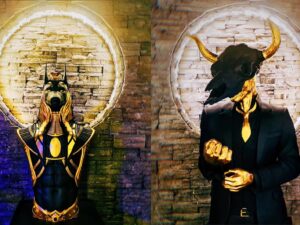

This colorful bust captures one of the most iconic digital characters – a Bored Ape styled in sailor hat, 3D glasses, and tie-dye shirt. The sculpture was printed and hand-finished with remarkable detail, showcasing both artistic flair and manufacturing precision.

Project Overview

The 3D model was recreated based on a digital collectible, emphasizing its expressive features and distinctive accessories. The goal was to bring the playful pop-art style of NFTs into a tangible form while preserving every recognizable element – from the blue-and-red 3D glasses to the anchor-marked hat.

Printing Quality

The bust was printed using SLA resin technology, chosen for its smooth surface and fine detail accuracy. The print exhibited crisp edges around the glasses frame and facial contours, with no visible layer lines. After curing and sanding, the surface was carefully primed and airbrushed with gradient tones to reproduce the tie-dye pattern and subtle shading on the face. The stubble texture and anchor symbol were painted with precise masking, highlighting the craftsmanship behind the finish.

Result

The final piece looks vivid, refined, and solid – a perfect blend of digital design and collectible craftsmanship. Each color transition is soft and even, and the smooth matte finish adds a premium texture.

Bring Your Characters to Life with FacFox

Whether it’s a game model, NFT avatar, or original digital sculpture, FacFox’s SLA and resin 3D printing services can transform your files into real, display-ready art pieces. We offer custom painting, airbrushing, and finishing to capture every shade and emotion of your design.

From high-detail miniatures to full-scale character busts, FacFox helps creators and collectors turn imagination into reality – with museum-grade surface quality and vibrant paintwork.

¤æē Start your custom sculpture project today at FacFox.com.

Solution

- Step 1: The reference NFT artwork was reviewed and key visual traits (sailor hat, 3D glasses, tie-dye shirt) were documented.

- Step 2: A high-fidelity 3D bust model was prepared; proportions were adjusted, and fine facial features were defined to match the reference.

- Step 3: The model was scaled to display size, wall thickness was optimized, and internal hollowing with drainage holes was added for resin efficiency.

- Step 4: Print orientation was selected and custom supports were generated to protect facial edges, ear rims, and the glasses frame.

- Step 5: The part was printed with SLA resin at fine layer height to achieve smooth surfaces and crisp edges.

- Step 6: The print was rinsed in IPA and fully UV-cured to reach final material strength and paint readiness.

- Step 7: Supports were removed carefully; nubs were trimmed and local surfaces were spot-sanded to restore contours.

- Step 8: Minor pinholes and layer transitions were filled with putty; the surface was block-sanded to a uniform matte.

- Step 9: A neutral primer was applied to reveal defects; iterative wet-sanding was performed until a consistent finish was achieved.

- Step 10: Base colors were airbrushed; skin tones and shirt foundation were laid down with smooth gradients.

- Step 11: The tie-dye effect was built with layered masks and soft passes; color transitions were feathered for a natural swirl.

- Step 12: Hard-edge details (anchor emblem, shirt collar lines) were masked and painted for sharp separation.

- Step 13: Facial micro-details (stubble dots, nose shading, ear shadows) were added with fine brushes and controlled washes.

- Step 14: The 3D-glasses lenses were coated with a clear gloss; the remaining surfaces received a protective matte varnish.

- Step 15: Final QA was conducted; color fidelity, edge cleanliness, and seam integrity were inspected under diffuse and raking light.

- Step 16: The bust was photographed for records and then packaged with custom foam to prevent abrasion and point-load damage.