- FDM 3D Printed Dessert Surprise Ring Box

- Handheld 3D Scanning Model Aircraft for Reverse Engineering

Gallery

About Project

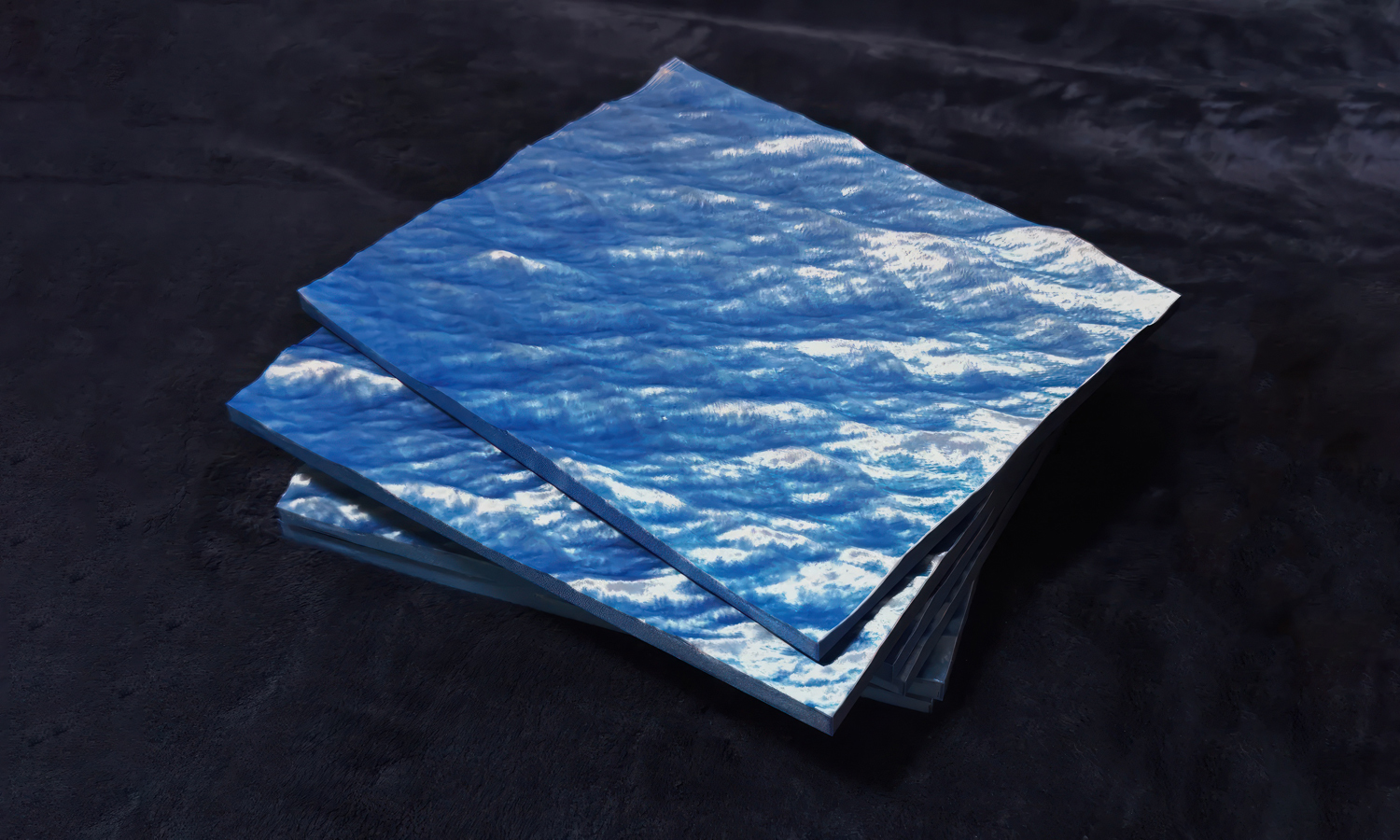

At first glance, it may look like a photograph of the open sea – but this mesmerizing piece is actually FDM 3D printed using silk-like PLA filament. Created by Jupiter Picnic Lab, this wall decoration captures the dynamic texture and shimmering color of ocean waves with striking realism.

To achieve this effect, the designer experimented repeatedly with model modifications, fine-tuning the 3D geometry to better emulate the natural undulation of water. The result? A sculptural illusion that feels alive with motion.

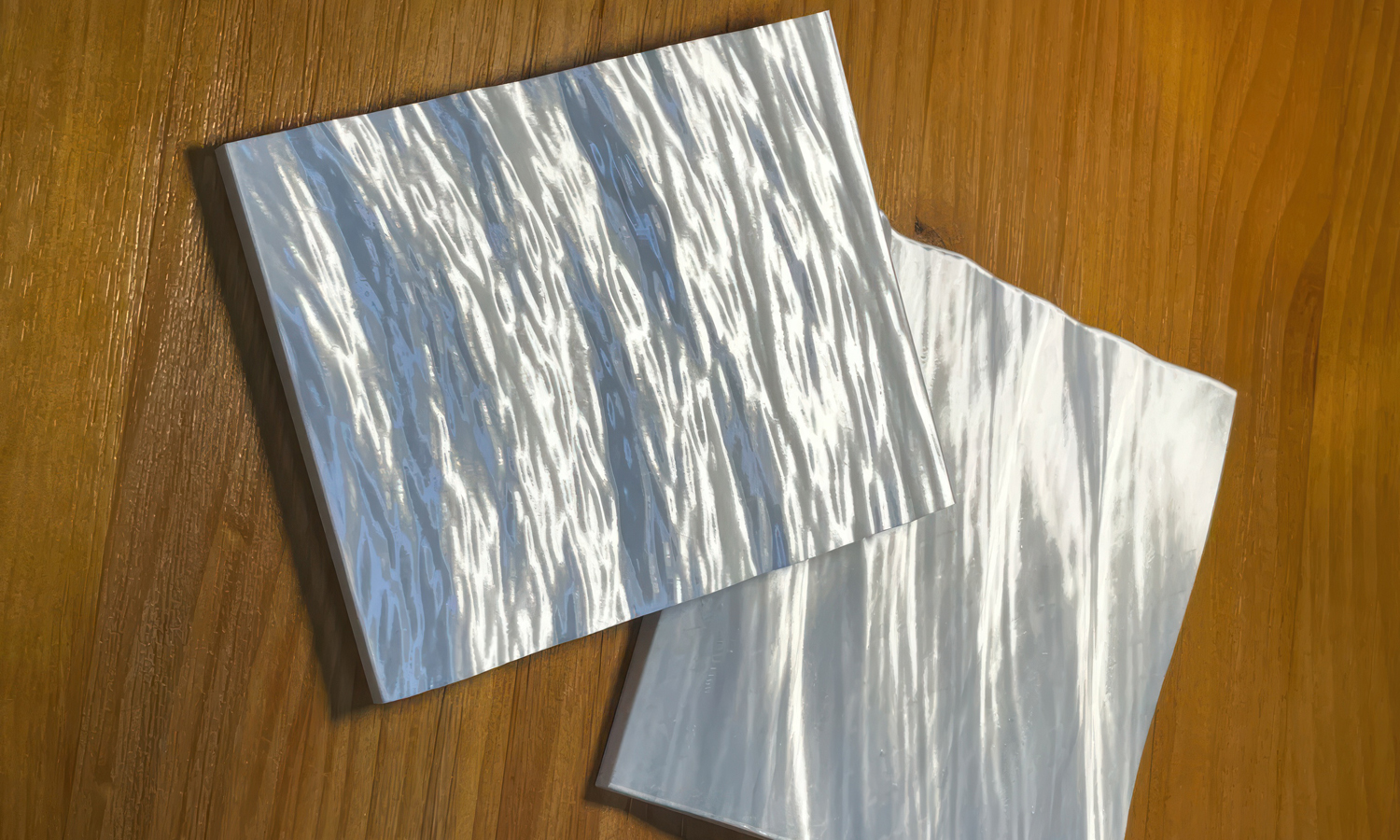

Vertical Printing: A Strategic Choice

Instead of printing the waves flat, the model was oriented vertically. This clever approach minimized visible layer lines on the wave surface, enhancing the smoothness and flow. The added benefit? Layer lines mimic water ripples, further enriching the visual texture.

Dual-Color Silk PLA: Shifting Tides of Light

The piece was printed with two shades of silk-like PLA filament, chosen for their ability to reflect light differently depending on viewing angle. By precisely controlling the print direction, the designer could manipulate how each area reflects light, subtly shifting the color and mood of the “water.”

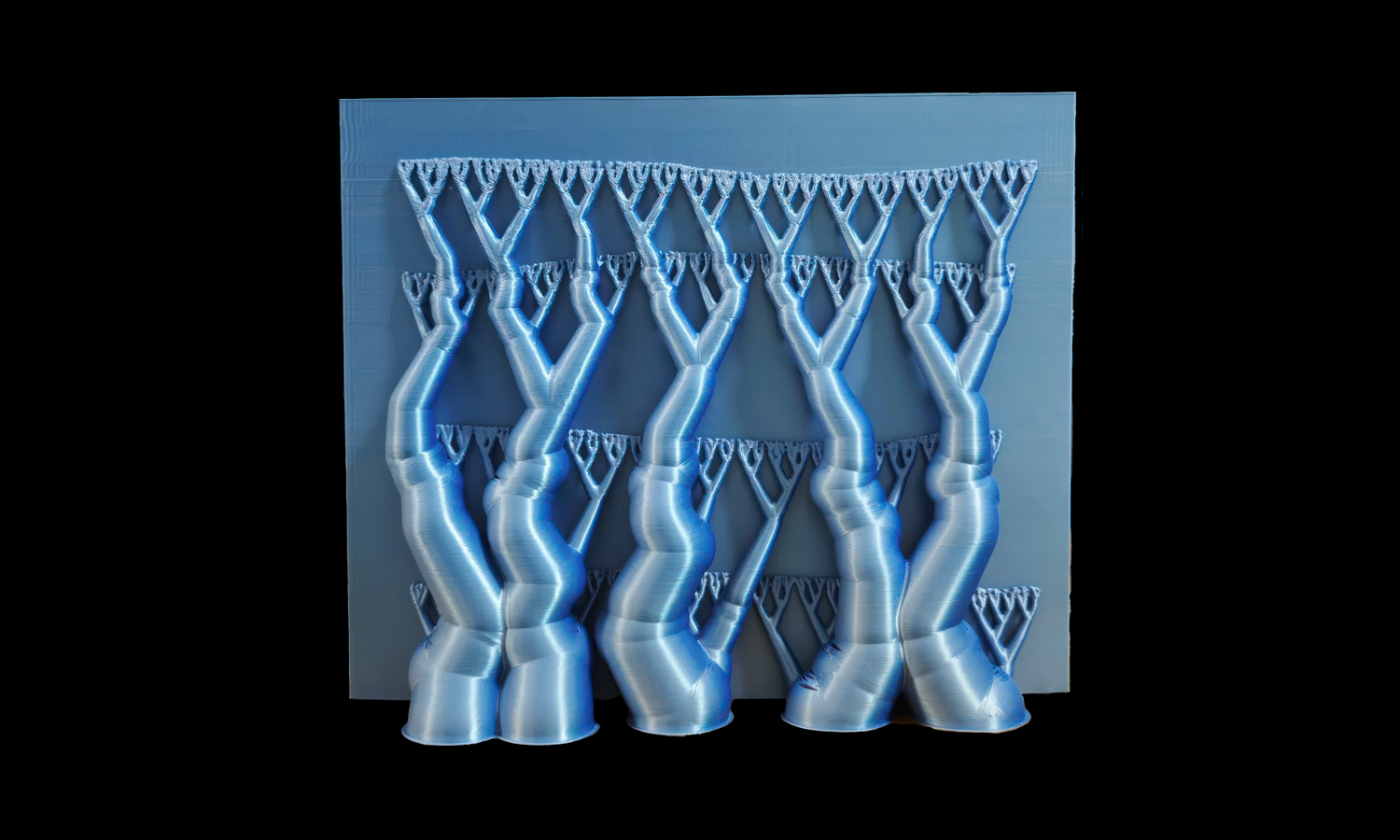

Sculptural Supports, Not Just Functional

Even the support structures used during printing were artful – tree-like forms designed to hold the model delicately, while minimizing contact and ensuring easy removal without surface damage.

This project is a stunning example of how FDM 3D printing can transcend utility and enter the realm of fine art – combining digital design, material science, and visual poetry. Jupiter Picnic Lab reminds us that even PLA filament can become ocean waves, given enough creativity and iteration.

Solution

- Step 1: A 3D model of ocean waves was digitally sculpted and repeatedly refined to enhance the realism of the wave contours and surface undulations.

- Step 2: The final model was reoriented vertically to reduce horizontal layer lines and to better simulate the natural flow and texture of water.

- Step 3: Two shades of silk-like PLA filaments were selected for their shimmering, light-reflective properties that change with viewing angle.

- Step 4: Print direction was carefully controlled to influence how light interacts with the wave surface, maximizing the dynamic visual effect.

- Step 5: The model was sliced with tree-style supports to minimize contact points and preserve the delicate surface during post-processing.

- Step 6: The model was printed on a large-format FDM printer with fine layer resolution, ensuring smooth gradients and consistent form.

- Step 7: Supports were carefully removed, and the final piece was cleaned and prepared for mounting as a wall decoration.