- ¤É┤Warm 2026 Spring Festival Greetings &┬ĀHoliday Service Pause Notice (Feb.7-23)

- Precision Laser-Cut Galvanized Steel and 3D Printed PLA Frames

Material Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

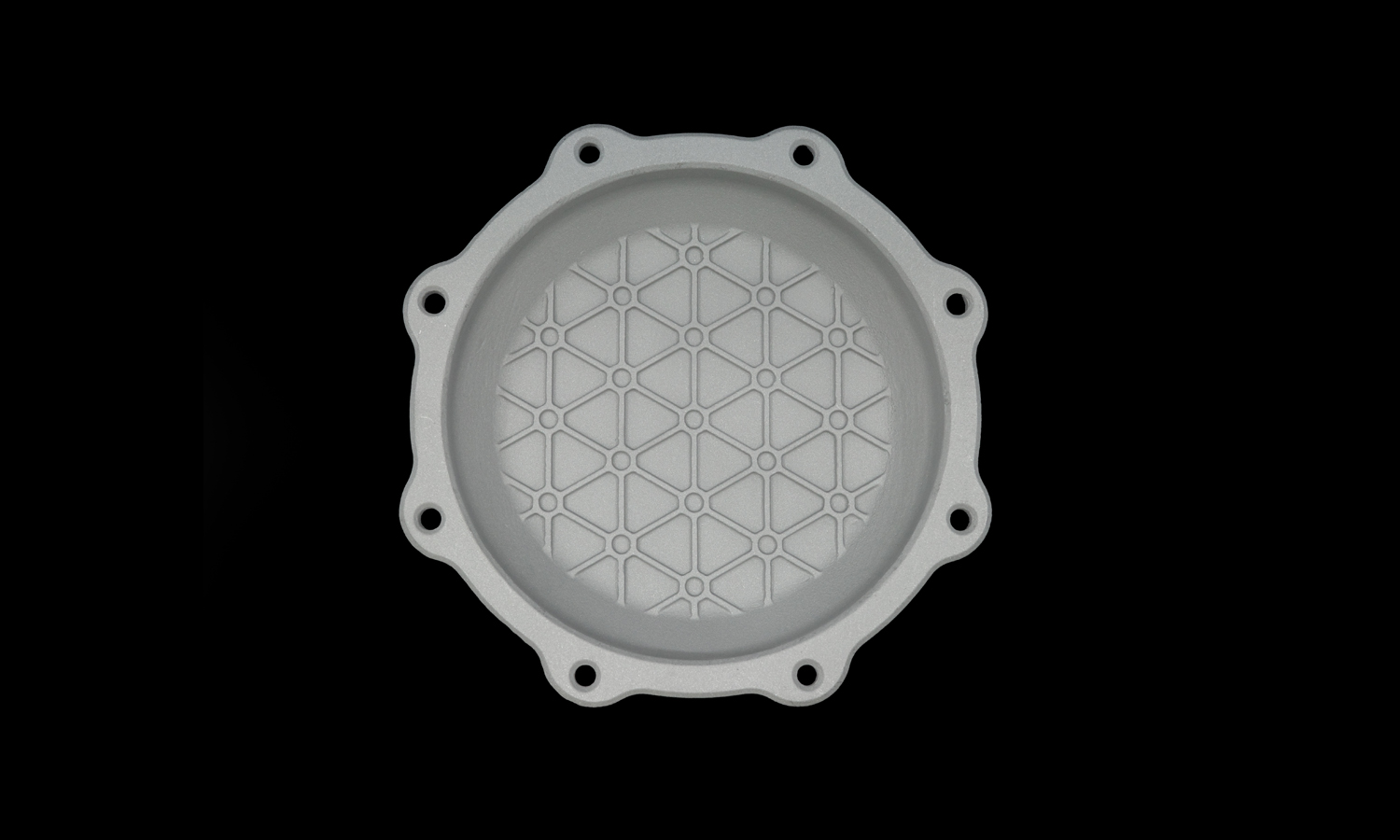

This impressive component is a masterclass in modern engineering, showcasing the true power of Selective Laser Melting (SLM). At first glance, you see a robust, dome-shaped housing, but the real magic is hidden on the inside.

Engineering Excellence: The Isogrid Advantage

The interior features a high-performance isogrid patternŌĆöa triangular reinforcement structure famously used in aerospace and satellite design. By utilizing this geometry, the part achieves an incredible strength-to-weight ratio that would be nearly impossible (and prohibitively expensive) to machine traditionally. The exterior is equally functional, featuring integrated cooling fins to dissipate heat and a precision-engineered 8-hole flange for secure, pressure-tight mounting.

Why SLM Aluminum?

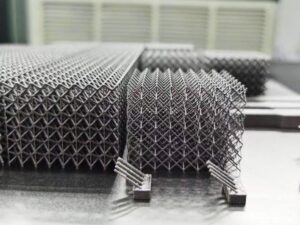

This part is 3D printed using AlSi10Mg, a high-strength aluminum alloy. Using SLM technology allows for:

- Complex Internal Geometries: Creating the lattice reinforcement without the need for molds.

- Weight Reduction: Removing every unnecessary gram of material while maintaining structural integrity.

- Monolithic Design: Consolidating what would typically be multiple parts into a single, high-performance component.

The “as-printed” matte finish is a hallmark of the SLM process, providing a professional, industrial look that is ready for functional testing or high-end end-use applications.

Bring Your Designs to Life with FacFox

If youŌĆÖre looking to push the boundaries of whatŌĆÖs possible, FacFox is your go-to partner for professional Metal 3D Printing services. We specialize in SLM technology, offering high-precision aluminum printing that turns complex CAD files into high-performance reality. Whether you need lightweight aerospace brackets, custom heat sinks, or reinforced housings like the one shown here, FacFox provides industrial-grade quality with rapid turnaround times. Upload your design to FacFox.com today and get an instant quote to start your next project!

Solution

- Step 1: The 3D CAD model was digitally sliced into thin horizontal layers to create a precise printing roadmap.

- Step 2: A thin, uniform layer of AlSi10Mg aluminum powder was spread across the build platform by a recoater blade.

- Step 3: A high-powered fiber laser was used to selectively melt and fuse the metal powder according to the cross-section of the part.

- Step 4: The build platform was lowered, and the process was repeated layer-by-layer until the full 3D geometry was realized.

- Step 5: The completed part was carefully removed from the powder bed, and excess material was reclaimed for future use.

- Step 6: Support structures were mechanically detached, and the component was subjected to a stress-relief heat treatment to ensure structural stability.

- Step 7: The surface was bead-blasted to achieve the uniform, matte industrial finish seen in the final product.