Gallery

About Project

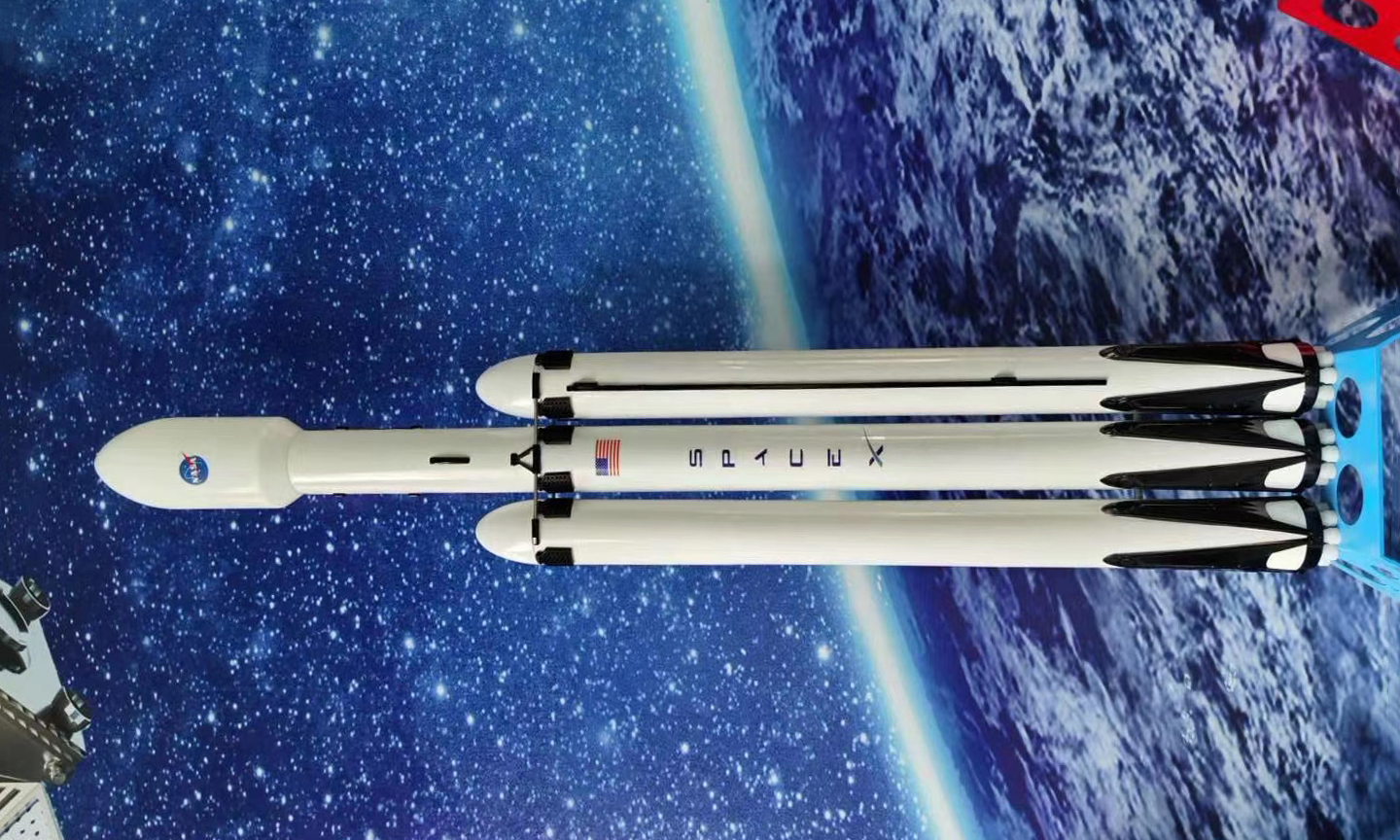

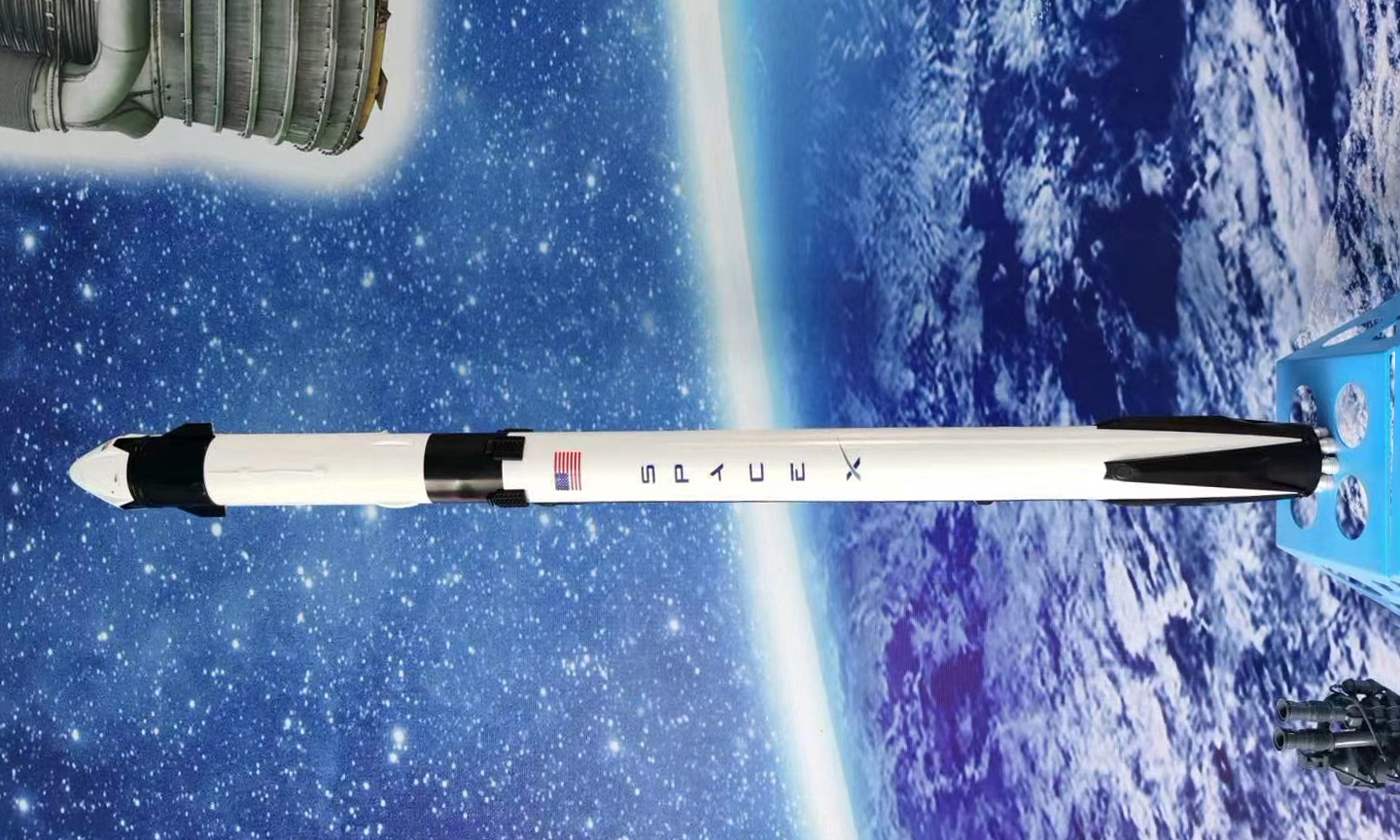

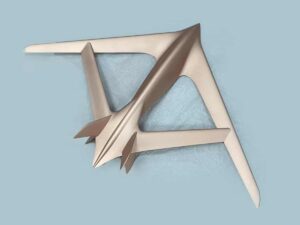

Designated by an aerospace museum, we printed the scale models of SpaceX's products. SpaceX is the innovative and ambitious private aerospace manufacturer founded in 2002 by Elon Musk, and it boldly went where no aerospace startup has gone before.

Falcon 9 is a reusable, two-stage rocket designed and manufactured by SpaceX for the reliable and safe transport of people and payloads into Earth orbit and beyond. Falcon 9 is the worldŌĆÖs first orbital-class reusable rocket. Reusability allows SpaceX to refly the most expensive parts of the rocket, which in turn drives down the cost of space access.

Falcon Heavy is the most powerful operational rocket in the world by a factor of two. With the ability to lift into orbit nearly 64 metric tons (141,000 lb) Falcon Heavy can lift more than twice the payload of the next closest operational vehicle, the Delta IV Heavy. Falcon Heavy is composed of three Falcon 9 nine-engine cores whose 27 Merlin engines together generate more than 5 million pounds of thrust at liftoff, equal to approximately eighteen 747 aircraft.

The Dragon spacecraft is capable of carrying up to 7 passengers to and from Earth orbit, and beyond. It is the only spacecraft currently flying that is capable of returning significant amounts of cargo to Earth, and is the first private spacecraft to take humans to the space station.

Solution

- Step 1: Download the 3D models of the SpaceX rockets and spacecraft on some 3D model platforms.

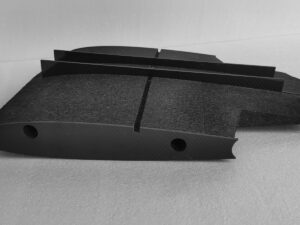

- Step 2: Add supporting structure onto the models and 3D print them with SLA 3D printer using SLA Tough Resin.

- Step 3: Remove excess material and the supporting structure, wash the parts with automated cleaner, then post-cure the rotating parts with UV.

- Step 4: Make tiny adjustments with sandpaper and tweezer, then spray with UV-oil.

- Step 5: Screen-print the pattern and water transfer print the carbon fiber texture.