Material Resin

Quantity 100 pcs

Price Range $100-1,000

Lead Time 20 workdays

Gallery

About Project

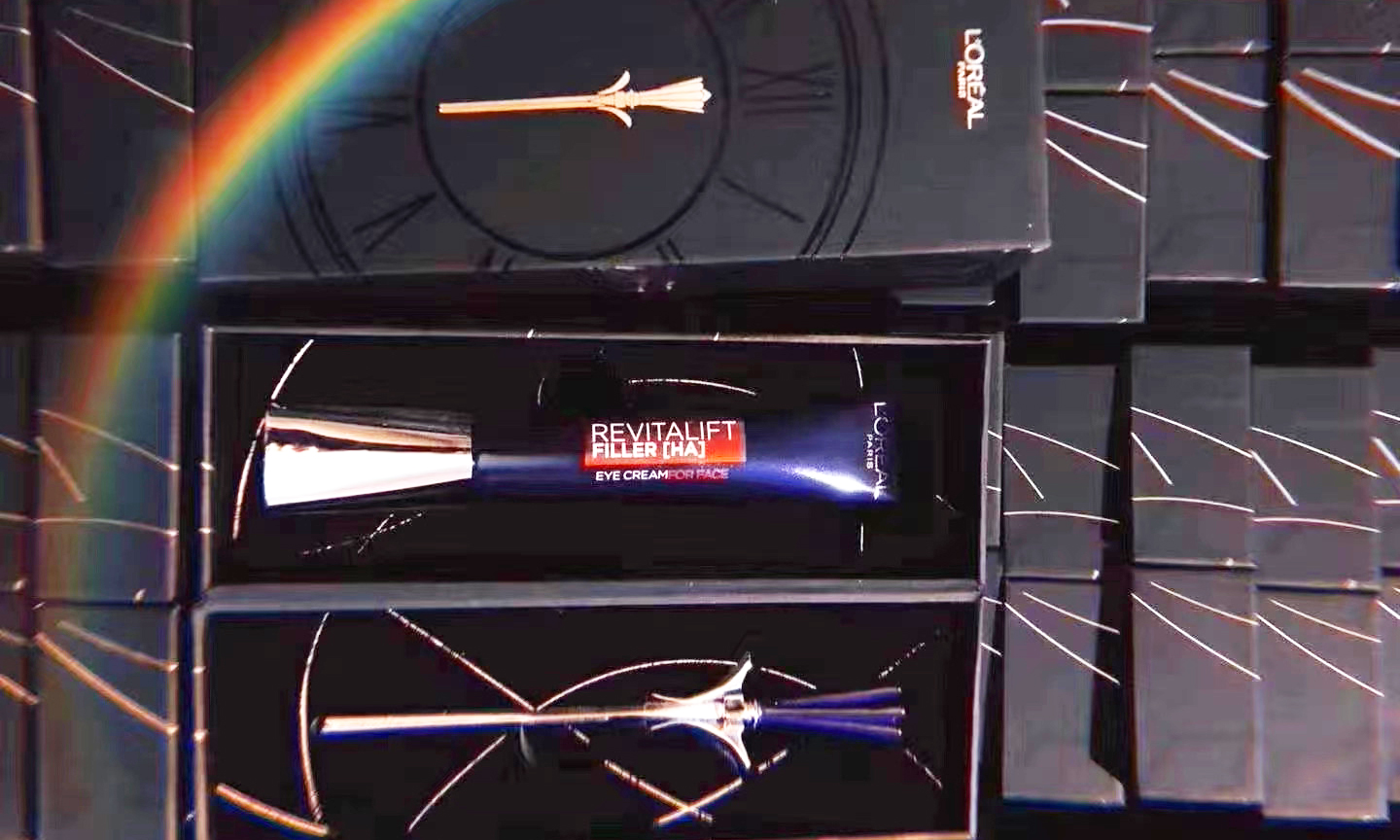

Revitalift Filler Eye Cream is the star product of L'Oreal. In 2019, L'Oreal invited a famous actor, Zhu Yilong, to cast in the advertisement. In the 4 mins video, Zhu Yilong became a wrinkle carver, whose duty was to add wrinkles on the face of people.

As time goes by, aging wrinkles grow, and those who stay up too late will have wrinkles earlier. Sleep wrinkles are created and reinforced when the face is compressed against a pillow. However, some of the wrinkles can be flattened by using proper skin care products, facial massage, regular daily schedule, and enough exercise.

To boost the sales of the Revitalift Filler Eye Cream, L'Oreal customized 100 pieces of the wrinkle carving tool in the ad as premium gifts. It really attracted a lot of fans to participate in the sales promotion.

Solution

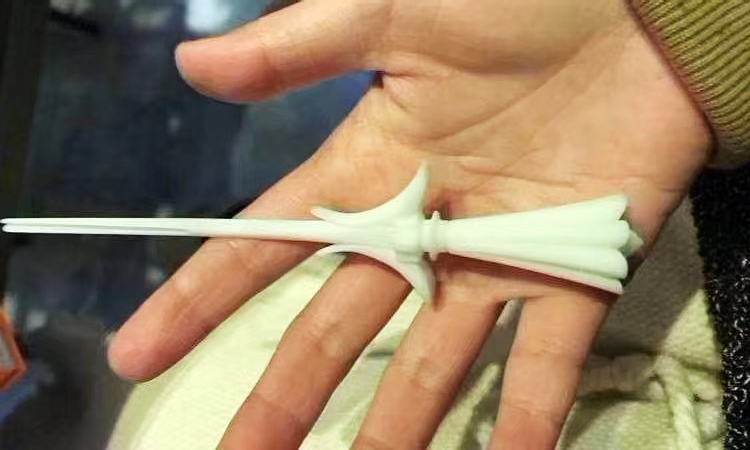

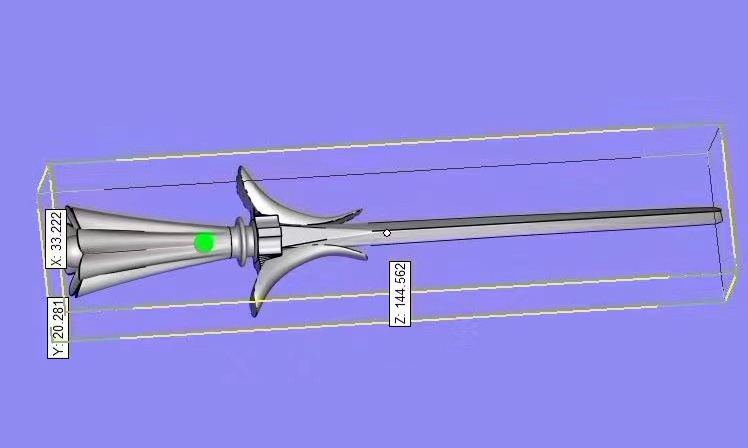

- Step 1: The shape of the wrinkle carving tool is specially designed by the artist. Looking a little complex, it’s indeed nothing difficult for SLA 3D printing technology. 3D print the master pattern with SLA Generic Resin SD. Carefully polish the master patterns with sandpaper and grater.

- Step 2: Apply the release agent evenly onto the master pattern and dry the pattern. Proper pretreatment is necessary to avoid the demold failure like sticking onto the silicone mold.

- Step 3: Attach the master pattern onto the plate with superglue, and then encase the pattern with liquid silicone. It takes about 18ŌĆō24 hours averagely to form the mold tool and left to cure. Then move the mold to a vacuum chamber to remove the air bubbles inside.

- Step 4: Cut the mold and take out the master pattern. Then inject the ABS-like resin into the mold to form the auto parts. The parts are then sprayed into black. ABS-like is a general-purpose polyurethane plastic that simulates ABS thermoplastic. This material is a great choice for most product enclosures.