- SLA 3D Printed Formlabs High-temp Resin Barbed Hose Adapters

- Precision Metal 3D Printing for Next-Generation Earbuds

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

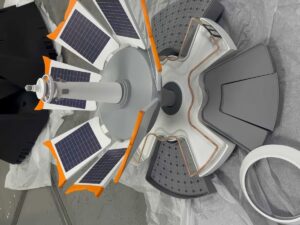

Have you ever wondered what an engineering-grade 3D print looks like? This sleek, “top-hat” shaped component is a

custom

cable pass-through or protective boot

, designed to bridge the gap between internal electronics and the outside world.

The two precision-cut ports on top are perfectly sized for standard cable glands, allowing wires to pass through while

keeping dust and moisture out. Its wide mounting flange and hollow interior make it an ideal “dome” for protecting

sensors or electrical junctions on flat surfaces like vehicle firewalls or industrial enclosures.

Is LCD Tough Black Resin Right for the Job?

When it comes to functional prototypes, the material is just as important as the design.

LCD Tough Black Resin

is specifically engineered to mimic the properties of

ABS plastic

. Unlike standard resins that can be brittle, this material offers:

-

High Impact Resistance:

It can survive drops and knocks without shattering. -

Flexibility:

It has a high “elongation at break,” meaning it can bend or snap-fit without cracking. -

Durability:

It is strong enough to be drilled, tapped, or bolted down under pressure.

While it’s a stellar choice for functional testing and low-stress end-use parts, remember that like most resins, it is

sensitive to prolonged UV exposure. A quick coat of UV-resistant paint can make it virtually indestructible for

outdoor use!

Bring Your Designs to Life with FacFox

Ready to turn your CAD files into high-performance parts?

FacFox

offers professional 3D printing services with a massive library of materials, including

LCD Tough Black Resin

. Whether you need a single prototype or a small production run, FacFox combines industrial-grade accuracy with

lightning-fast lead times.

Solution

- Step 1: Digital Design. A detailed 3D model was drafted using CAD software, incorporating specific tolerances for the mounting holes and

cable ports. - Step 2: Slicing and Preparation. The digital file was processed through slicing software, where optimal support structures were generated and layer

heights were defined. - Step 3: Vat Polymerization. The part was printed using an LCD-based 3D printer; ultra-violet light was projected through an LCD screen to

selectively cure the Tough Black Resin layer by layer. - Step 4: Initial Cleaning. Once the printing was completed, the part was removed from the build plate and submerged in an isopropyl alcohol

(IPA) bath to dissolve uncured resin. - Step 5: Support Removal. The temporary support structures were carefully detached from the flange and interior dome to prepare the

surfaces. - Step 6: UV Post-Curing. The component was placed inside a specialized UV curing chamber, where it was exposed to controlled light and heat

to reach its maximum mechanical strength and “tough” characteristics. - Step 7: Final Inspection. A manual finishing process was performed to smooth any remaining support marks, and the dimensions were verified

against the original design.