Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

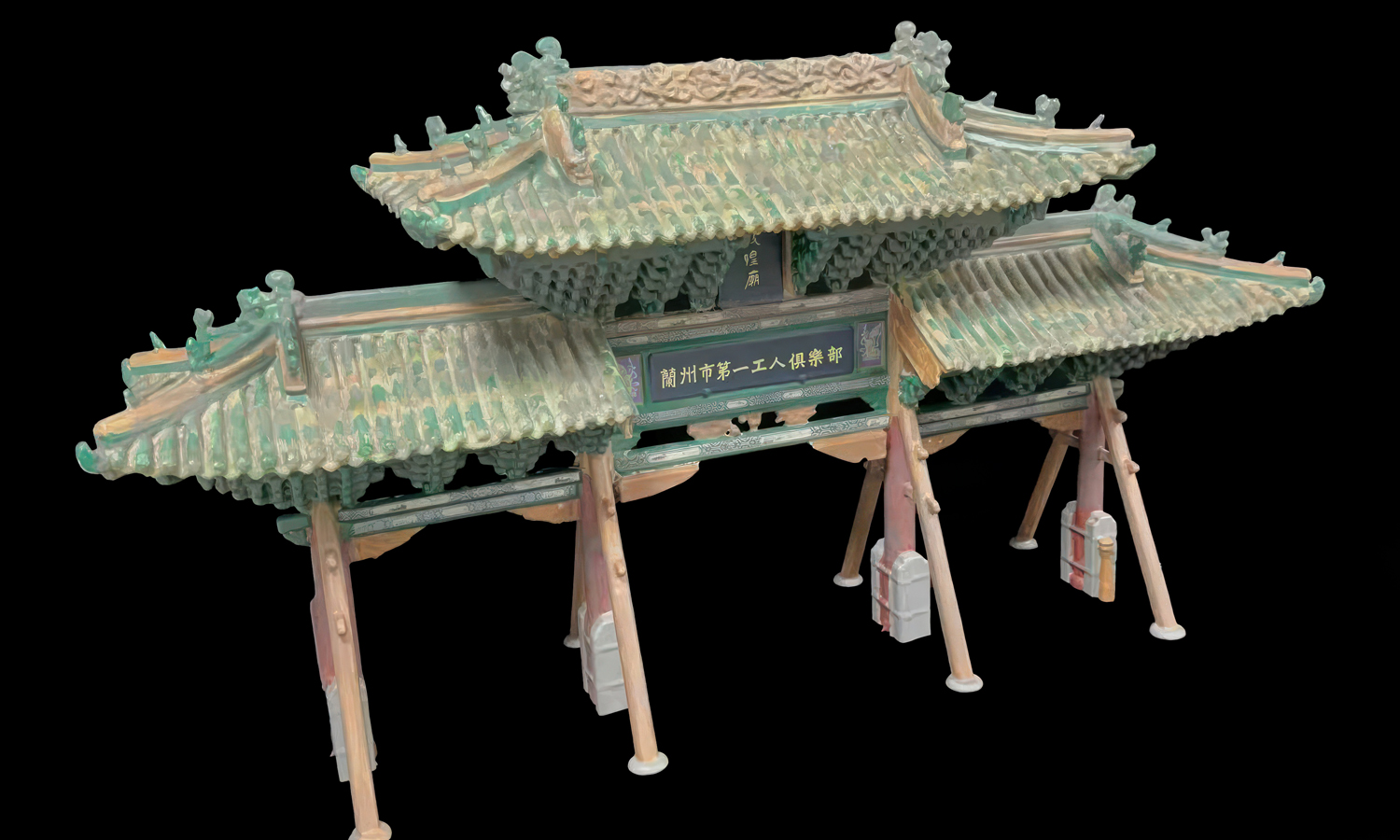

There is something profoundly satisfying about seeing historical architecture brought back to life in miniature. This recently completed project is a 3D-printed and hand-painted recreation of the iconic Lanzhou First Workers’ Club archway, and the results are a testament to the bridge between digital precision and traditional artistry.

From Digital Mesh to Tangible Art

The model captures the classic triple-gate Paifang structure with incredible fidelity. Printed in high-resolution resin, every intricate detail-from the complex dougong bracket systems to the ornamental ridge beasts-has been preserved.

The true soul of the piece, however, lies in the hand-painting. Rather than a flat, factory-finish look, our artists applied a layered glazing technique to the roof. The mottled greens and ochres mimic the weathered ceramic tiles found on ancient Chinese gates, while the crisp gold calligraphy on the central plaque provides a striking focal point. The addition of the structural support beams adds an extra layer of historical realism, showing the arch as it stood in its prime.

Why Miniature Scale Matters

By shrinking this massive structure down to a desktop scale, we can appreciate the architectural genius of the past from every angle. It’s no longer just a building; it’s a tactile piece of history that fits in the palm of your hand.

Bring Your Vision to Life with FacFox Whether you are looking to recreate a vanished historical landmark or prototype a brand-new design, FacFox is your ultimate partner for high-end fabrication. We offer industry-leading SLA 3D printing services for unmatched surface smoothness, paired with a world-class manual finishing and painting department. From technical architectural models to custom collectibles, FacFox handles the entire pipeline from file to final masterpiece. Visit us today to start your next project!

Solution

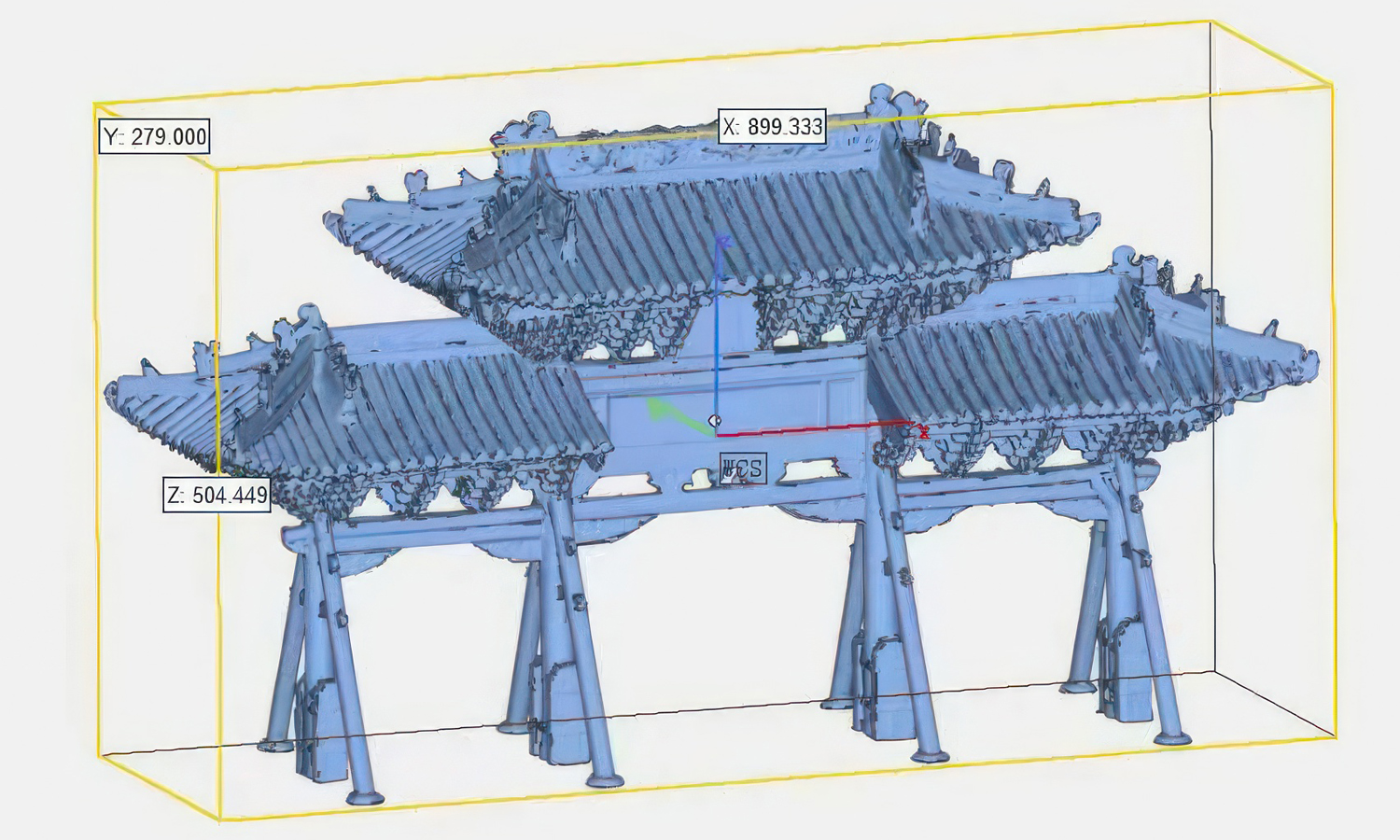

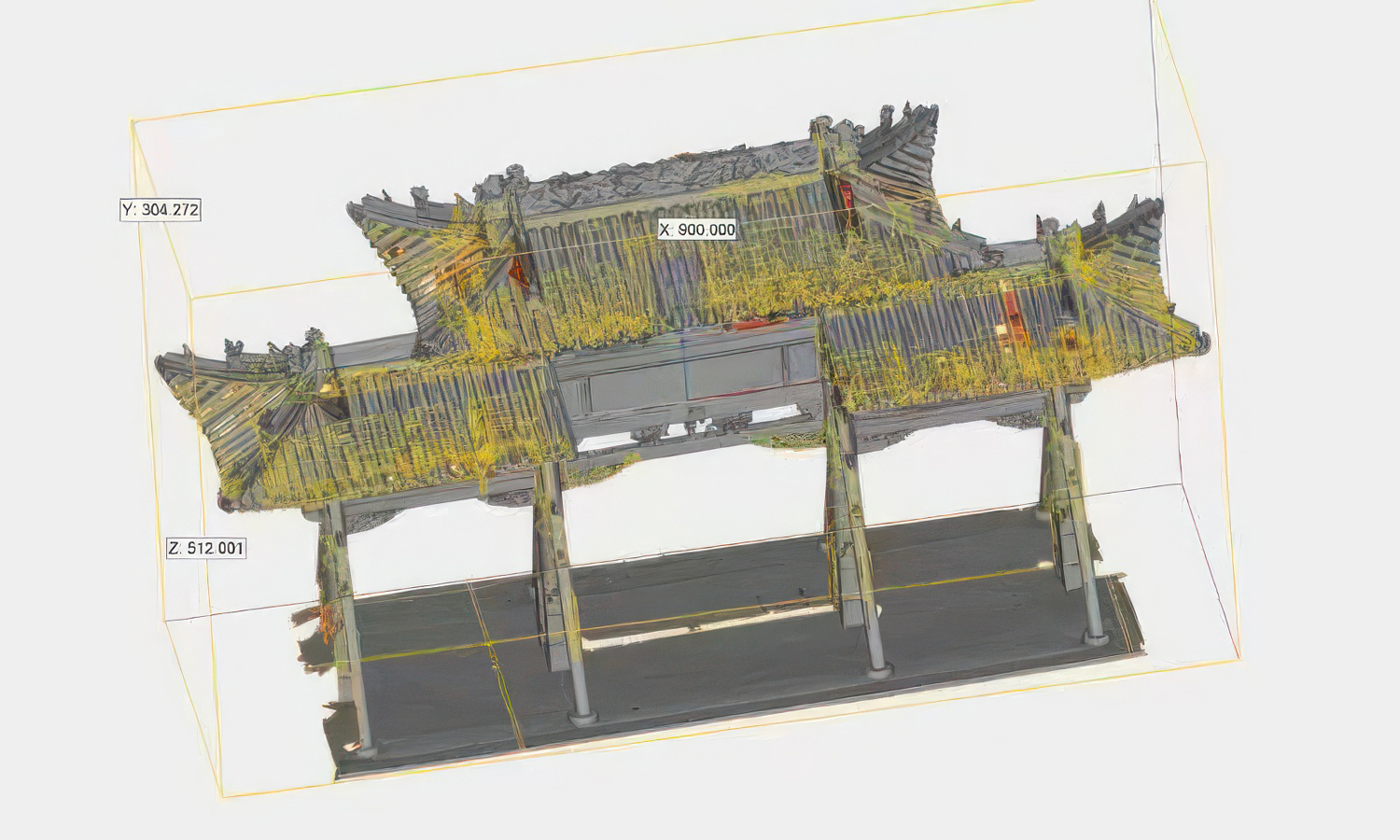

- Step 1: The architectural structure was meticulously converted into a high-fidelity 3D mesh and optimized for resin fabrication.

- Step 2: The model was printed using SLA (Stereolithography) technology to ensure the complex dougong brackets and roof textures were captured with maximum resolution.

- Step 3: The support structures were carefully removed, and the model was washed and UV-cured to achieve full structural rigidity.

- Step 4: A professional-grade primer was applied to the surface to create a uniform base for the subsequent color layers.

- Step 5: The roof tiles were hand-painted with a specialized glaze technique to replicate the weathered appearance of traditional green ceramics.

- Step 6: The calligraphy and decorative filigree were meticulously detailed using fine-tip brushes and metallic pigments.

- Step 7: A protective matte coating was applied to the structural pillars, while a semi-gloss finish was reserved for the tiled surfaces to enhance material realism.