- Mimaki 3D Printed Full-color Mermaid Diving into Ocean

- FDM 3D Printed Custom Motorcycle Connector Housing

Gallery

About Project

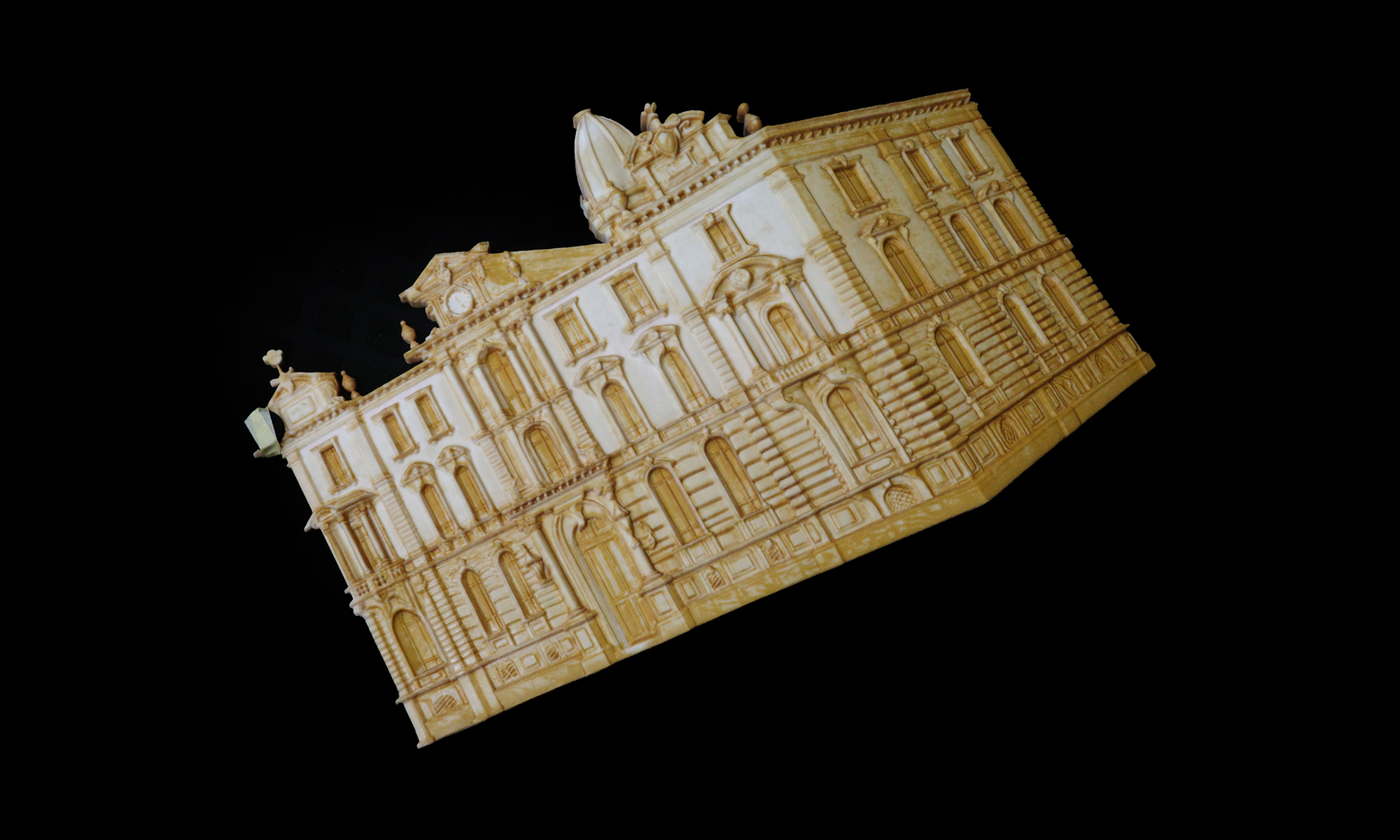

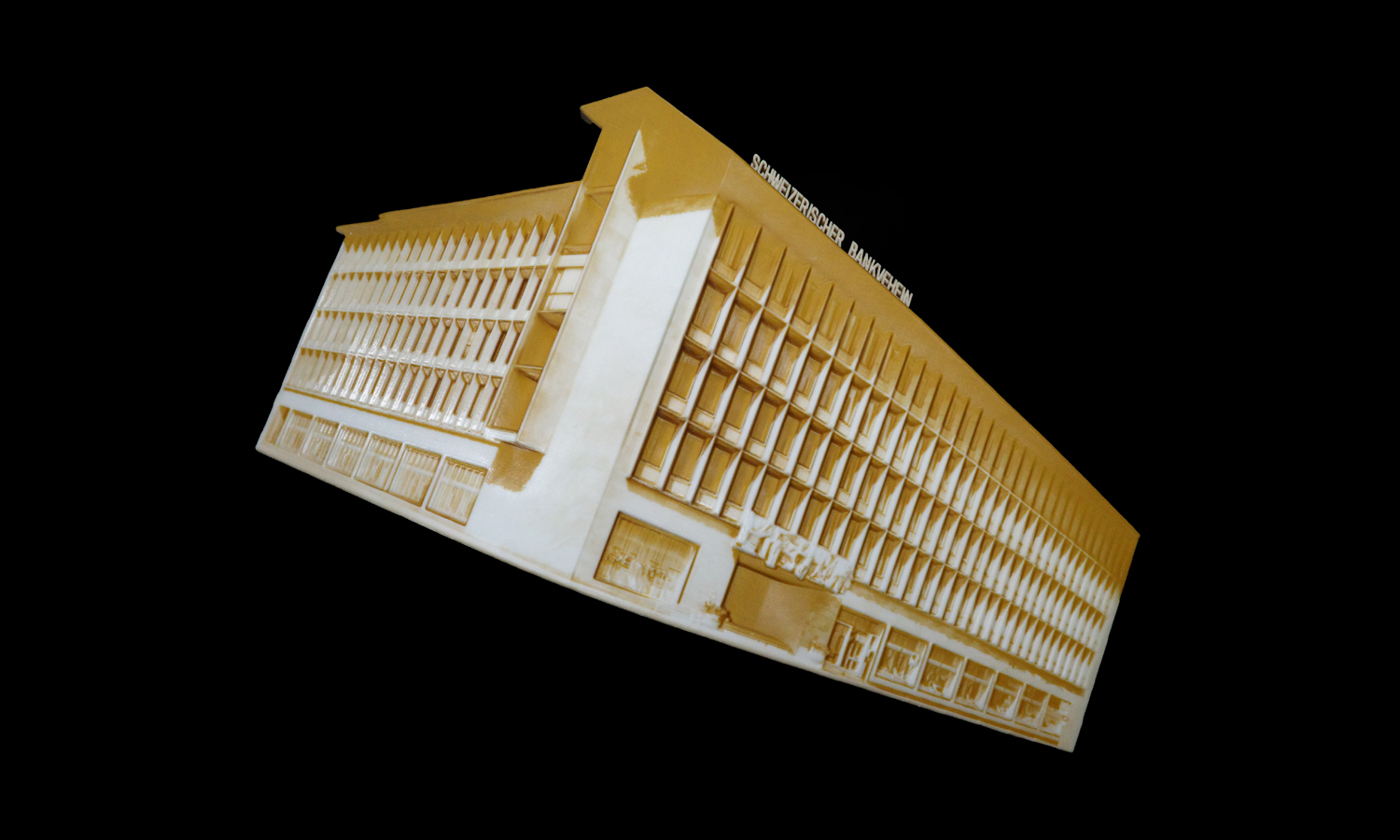

When architectural precision meets artistic intent, the results are breathtaking. In this project, we produced two highly detailed models-the modernist Schweizerischer Bankverein and a classical heritage structure-using industry-leading Mimaki full-color resin technology.

Unlike traditional models, the digital files provided by the client featured a forced perspective effect. By subtly tapering the geometry, the physical models replicate the way the human eye perceives these massive structures from a street-level vantage point. This design choice creates a “heroic” scale, making the models feel like immersive monuments rather than static miniatures.

The choice of Mimaki technology was critical for this project. Unlike porous sandstone, Mimaki’s UV-curable ink process allows for photorealistic color accuracy and the representation of fine architectural textures-from the sharp, clean lines of modernist concrete fins to the ornate, weathered masonry of a neoclassical dome. The colors are printed directly into the resin with stunning vibrancy, requiring no manual painting. These models serve as a perfect bridge between digital architectural rendering and physical reality.

Solution

- Step 1: The digital models were engineered with perspective-corrected geometry and high-resolution texture maps to ensure the color data was embedded directly into the 3D files.

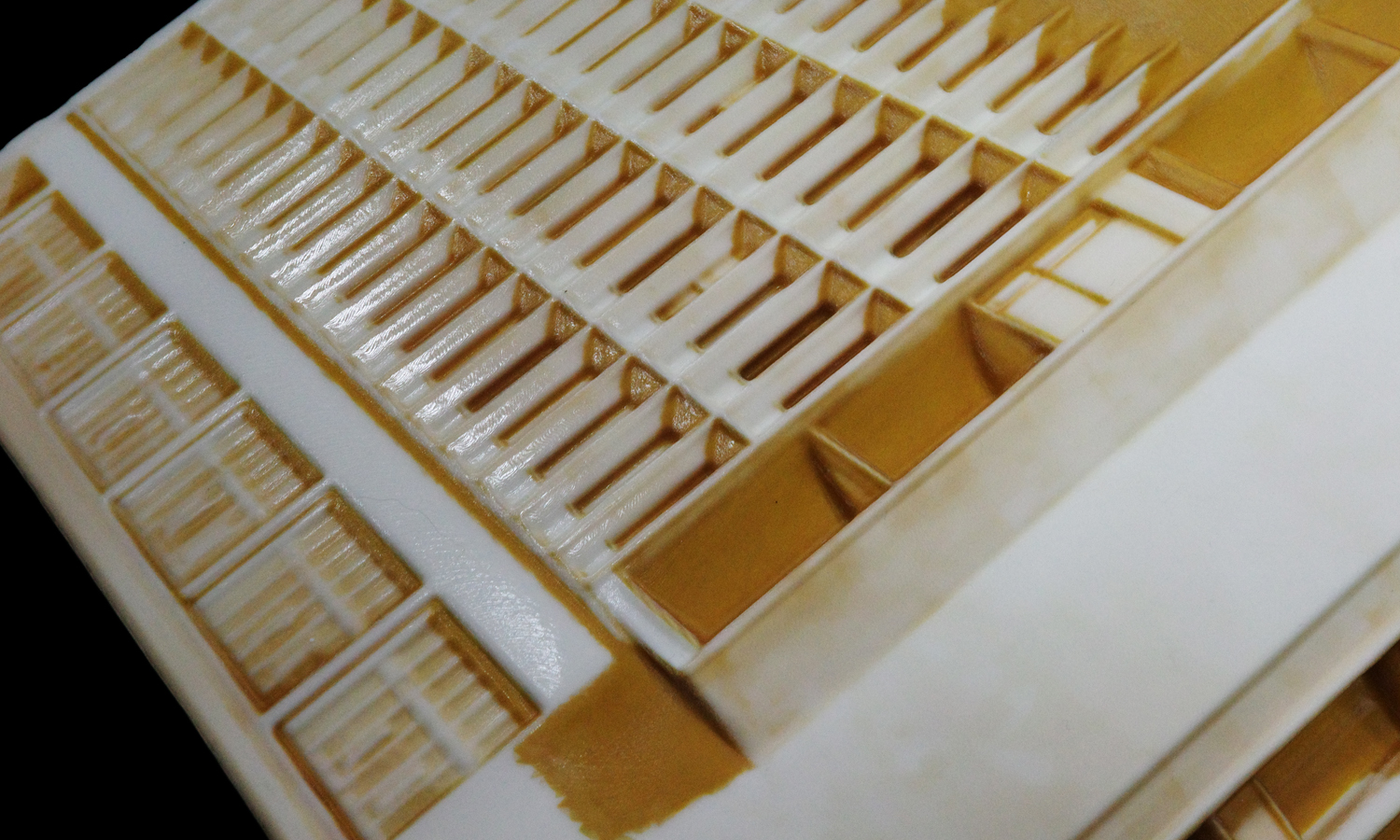

- Step 2: The files were processed through specialized slicing software, where a water-soluble support material was assigned to the overhangs, such as the window recesses and the protruding cornices.

- Step 3: Using piezoelectric inkjet heads, microscopic droplets of UV-curable liquid resin and CMYK color inks were deposited onto the build plate.

- Step 4: Each layer was instantly cured by a UV lamp, solidifying the resin and locking in the photorealistic color before the next layer was applied.

- Step 5: The models were fully submerged in a specialized cleaning tank, where the support material was dissolved, leaving behind the intricate, “floating” architectural details without any mechanical scarring.

- Step 6: A final protective coating was applied to the cured resin surfaces to enhance the color depth and protect the models from UV degradation.