- SLS 3D Printed Taihu Stone Minimalist Sculptural Lamp

- 3D Print in vibrant color and stunning detail with WJP Full-Color Resin! See more price and availability changes on material updates!

Gallery

About Project

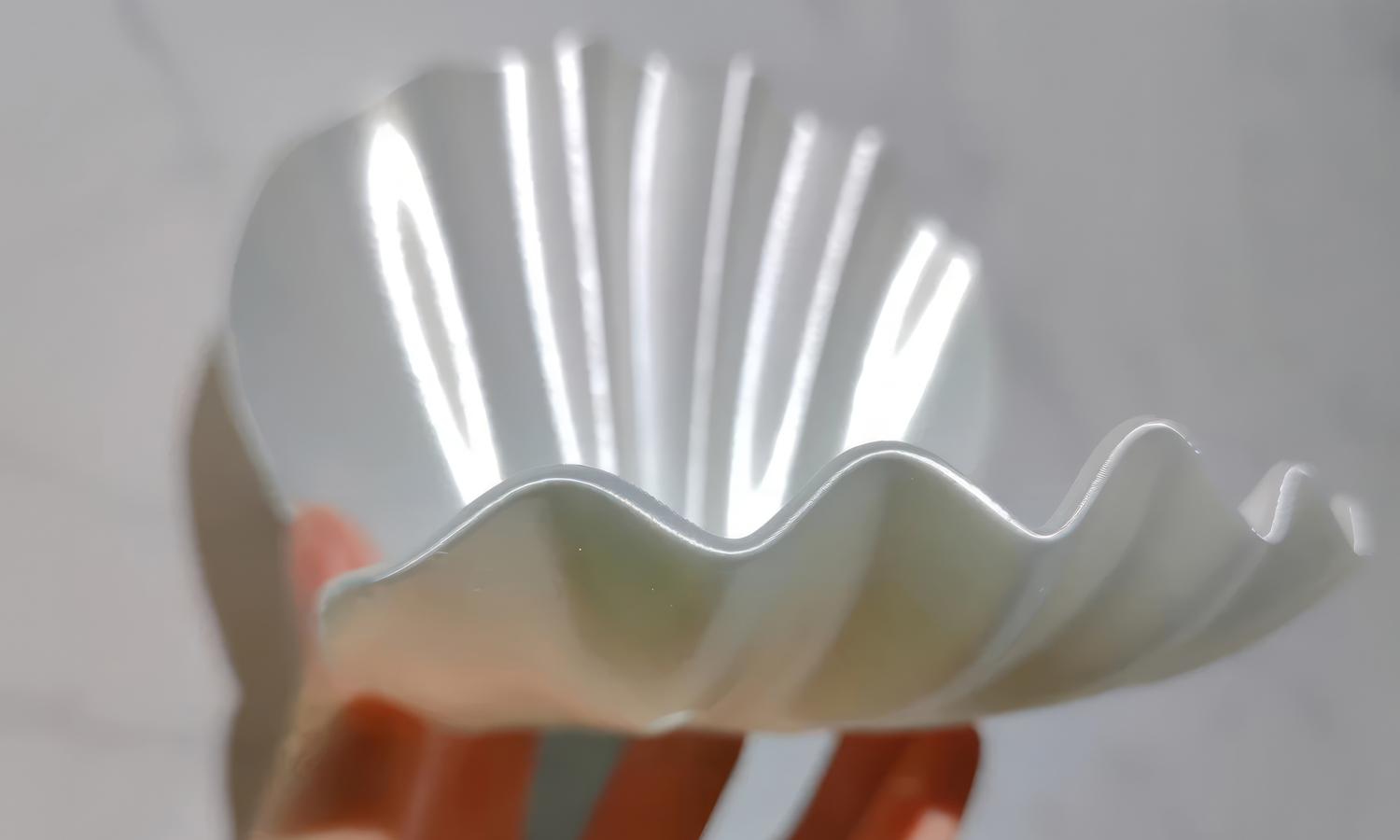

Bring seaside elegance into your everyday routine with this stunning clamshell soap holder, 3D printed to perfection using FDM technology. With its gently rippled form and pearlescent white finish, the design mimics a real seashell cradling a precious pearl-adding a whimsical and luxurious accent to your bathroom.

This piece isn’t just decorative-it’s practical too. The upward-curved shell base holds your soap securely and allows for quick drainage, keeping it dry and extending its life. Mounted gracefully against the wall, it frees up counter space and blends beautifully with marble or tile surfaces. Whether you’re into ocean vibes or simply love sculptural home accessories, this shell soap dish is both functional and eye-catching.

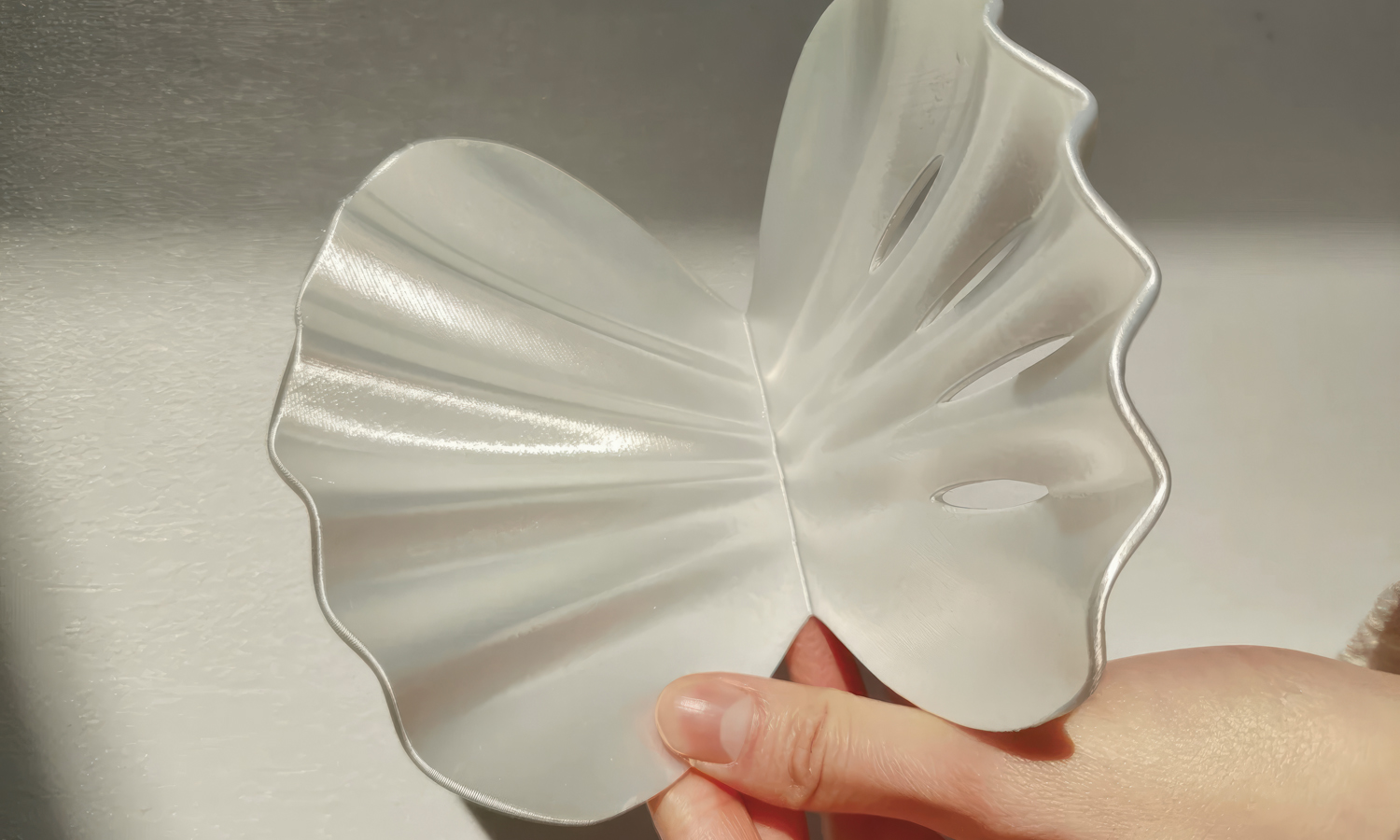

The holder was brought to life using Fused Deposition Modeling (FDM), a cost-effective 3D printing method that enables fast prototyping and small-batch production of complex forms. The layer lines give the surface a gentle texture, enhancing the pearlescent sheen and seashell-like realism.

Ō£© Want to make something just as creative?FacFox offers custom FDM 3D printing services to turn your imaginative concepts into practical, beautiful objects. Whether you’re designing home decor, accessories, or gifts, our team can help you select the right material, refine your model, and produce it with speed and precision. Let your ideas wash ashore-FacFox is here to make them real.

Solution

- Step 1: The 3D model of the clamshell soap holder was designed using CAD software, with attention to the organic curves and functional soap-holding structure.

- Step 2: The digital model was sliced into layers using slicing software, and print settings were adjusted to accommodate silk PLA filament for a smooth, glossy finish.

- Step 3: The sliced file was uploaded to an FDM 3D printer, and the printing process was initiated.

- Step 4: The soap holder was 3D printed layer by layer using silk PLA filament, which was extruded through a heated nozzle and deposited onto the print bed.

- Step 5: Upon completion of the print, the part was carefully removed from the build plate to avoid damaging the delicate curves of the shell.

- Step 6: Support structures, were removed, and the surface was lightly cleaned to retain the silk PLA’s natural sheen-no additional painting or coating was needed due to the material’s pearlescent quality.

- Step 7: Double-sided adhesive or mounting tape was applied to the back for easy wall installation, completing the transformation from concept to functional decor.