- SLA 3D Printed Clear Resin Honey Bear with Dual Color Finishing

- PolyJet 3D Printed Rubber Prototypes for Medical and Industrial Use

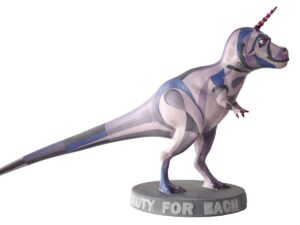

Gallery

About Project

These might look like freshly harvested fruits-but they’re not. What you’re seeing is a hyper-realistic 3D printed lychee and banana, created using Mimaki’s state-of-the-art full-color 3D printing technology. While the lychee rests beside a real leaf, its skin texture, color gradients, and even the subtle irregularities of its rind are 100% 3D printed. The banana, oversized and deeply bruised in all the right places, mimics the natural ripening process with striking accuracy.

This level of realism isn’t just eye-catching-it’s technically impressive. Mimaki’s 3D printers, particularly the Mimaki 3DUJ-553 and 3DUJ-2207, are among the only machines in the world capable of printing over 10 million unique colors directly into UV-cured resin. Instead of post-processing or painting, the color is embedded into the object as it’s being built. This means every pixel of color, every subtle transition from yellow to brown, every spot of red on the lychee’s surface is printed as part of the object itself.

What makes Mimaki truly stand out?

- Full-Color Output: Mimaki’s color capabilities surpass most other 3D printers on the market. The CMYK+White inkjet system allows for millions of vivid, continuous tones without manual painting or texture mapping.

- Fine Detail Reproduction: With a minimum layer thickness of just 19 microns, Mimaki printers capture intricate surface details-like the bumpy rind of a lychee or the subtle bruises on banana skin-with astonishing fidelity.

- Transparent and White Ink Support: The addition of white and clear resins opens the door to more complex visual effects, from semi-translucent objects to layered depth.

- Durability and Finish: Prints come out with a smooth, photo-quality finish and can be further enhanced with gloss or matte coatings.

These realistic fruit prints are not just novelties. They serve real purposes in fields like product design, food display, museum curation, film props, and educational modeling-where visual impact and authenticity are everything, and perishability is a problem.

At FacFox, we’re proud to offer Mimaki full-color 3D printing services to clients who demand the highest level of detail and realism. Whether you’re a product designer, artist, marketer, or educator, our team can help you turn your concept into a full-color masterpiece. With our deep manufacturing experience and strict quality control, you can trust us to deliver prints that look-and feel-like the real thing.

Let your ideas come to life with color, texture, and realism beyond imagination. Explore the power of Mimaki 3D printing with FacFox today.

Solution

- Step 1: 3D Model Preparation. A high-resolution 3D model of the fruit was created or scanned, including detailed surface geometry and a full-color texture map. The model was then processed and optimized for Mimaki’s slicing software.

- Step 2: Color and Texture Mapping. The color texture data (typically in OBJ or VRML format) was mapped precisely onto the geometry. Color fidelity was ensured using ICC profiles to match digital textures with printed CMYK output.

- Step 3: File Slicing and Print Setup. The model was sliced into hundreds of fine layers using Mimaki’s 3D Print Prep software. Print resolution and material settings were configured, including the use of support structures if required.

- Step 4: 3D Printing. The object was printed layer by layer using Mimaki’s UV-curable inkjet technology. Droplets of CMYK, white, and clear resins were selectively deposited and cured with UV light after each pass. Each layer reproduced both the color and shape of the fruit with micro-precision.

- Step 5: Support Removal. After printing, the model was carefully removed from the build tray. Any support material was dissolved or mechanically detached using recommended tools and solvents, taking care to preserve surface textures.

- Step 6: Post-Processing. The print was gently rinsed and dried. A matte or gloss coating was optionally applied to enhance the color vibrancy or mimic the natural surface finish of real fruits. No additional painting was required, as the color was printed directly into the object.

- Step 7: Quality Check and Finishing. The final product underwent visual and dimensional inspection. Color accuracy, detail sharpness, and overall finish were evaluated to ensure the model met FacFox’s quality standards.