- SLA 3D Printed Car Headlight Assembly Resin Prototype

- CNC Machined Aluminum Alloy Coolant Outlet Automotive Assembly

Gallery

About Project

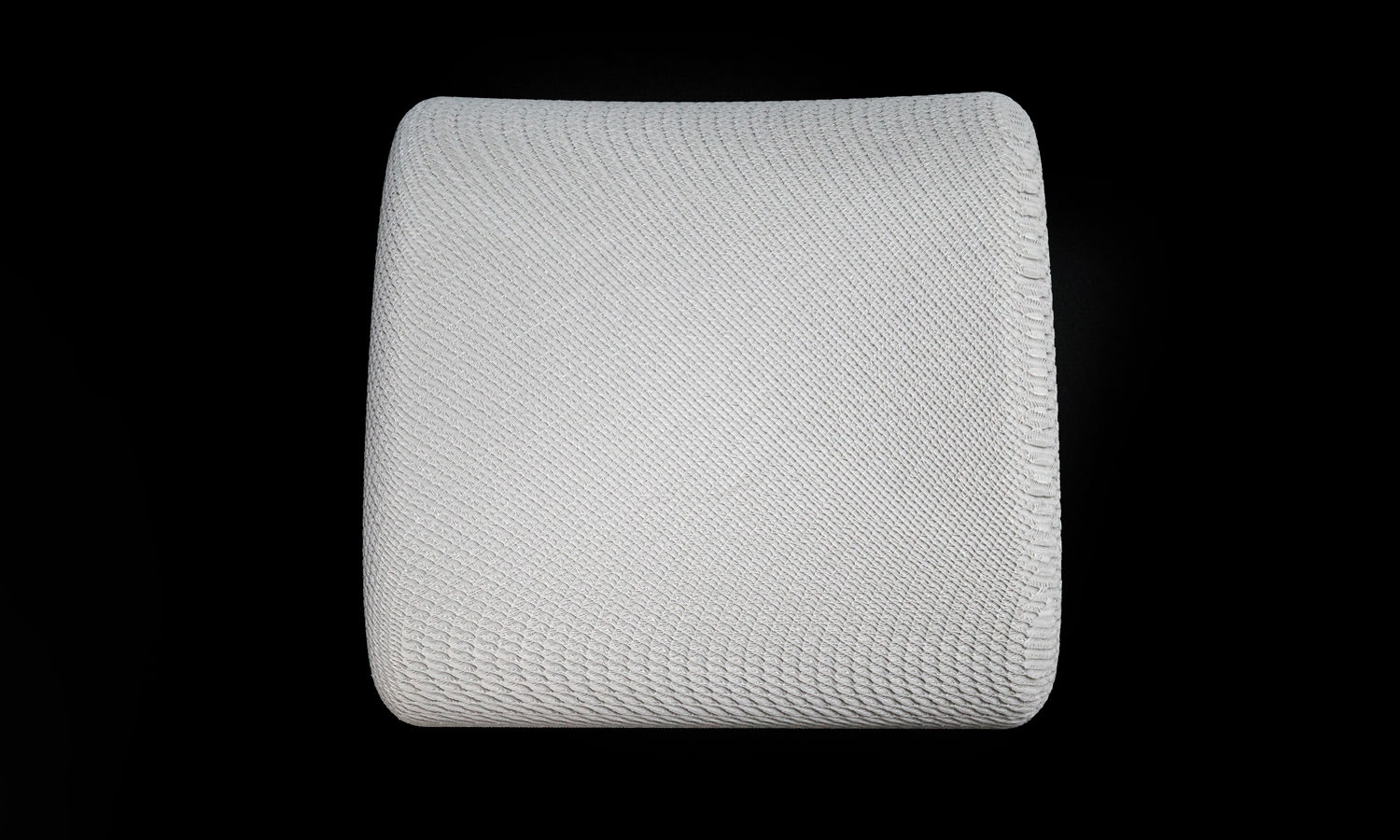

Tired of your chair treating your back like it’s made of steel? Say hello to comfort and support with a futuristic twist-introducing the FDM 3D Printed PEBA Lumbar Support Cushion, exclusively made with FacFox’s cutting-edge 3D printing service and the high-performance material PEBA (Polyether Block Amide).

The Cushion: Ergonomic, Stylish, and Just Bouncy Enough

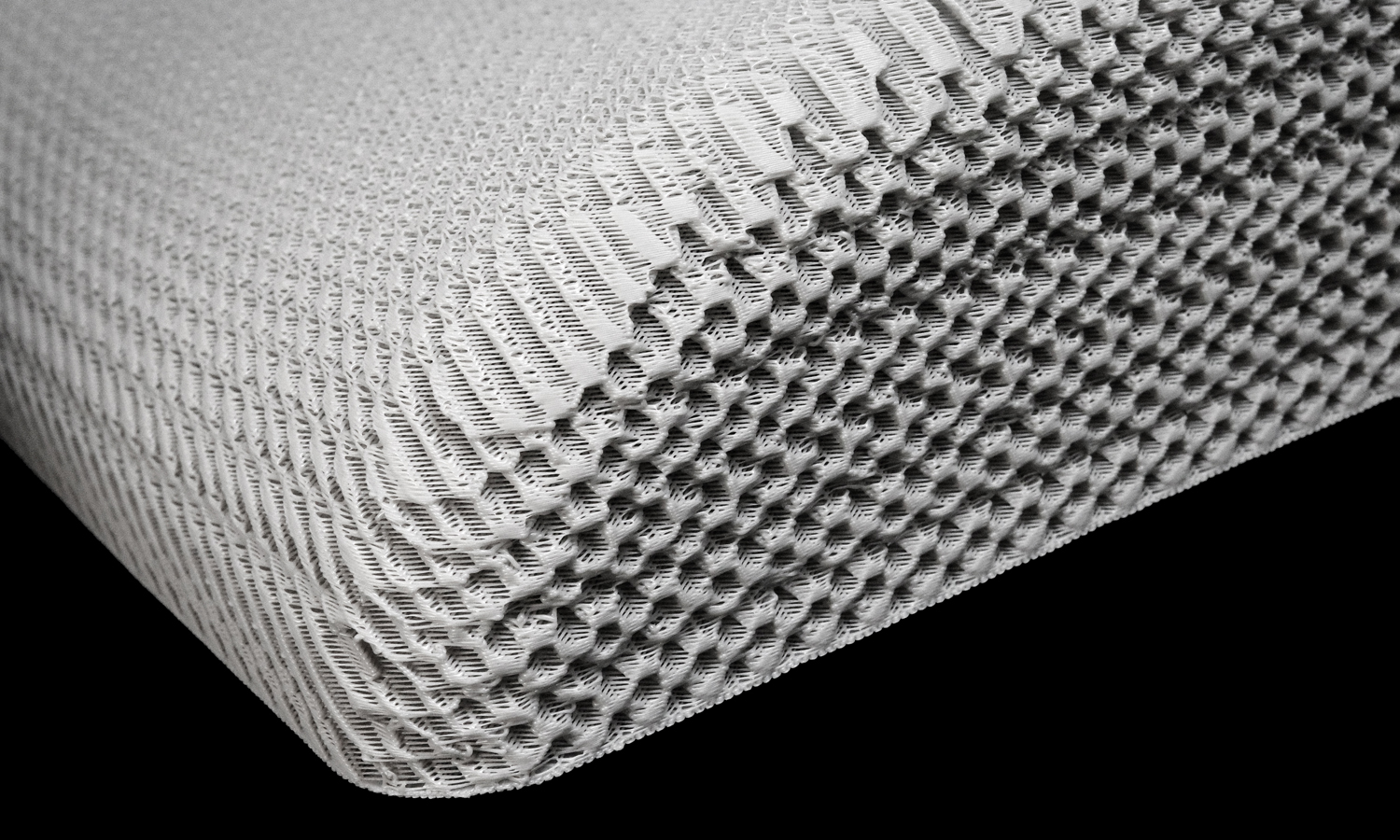

This isn’t your grandma’s back pillow. Our lumbar support cushion features a precision-designed grid structure tailored to the natural curve of your spine. It delivers responsive, springy support that adjusts as you move-ideal for those long hours in the office or intense gaming marathons. It’s lightweight, breathable, and won’t flatten like traditional foam pads over time.

Thanks to FDM 3D printing, every curve and contour is printed to perfection. No lumps. No sag. Just clean, consistent comfort.

What’s So Special About PEBA?

Glad you asked. PEBA is the superhero of 3D printing materials. Originally famous for its slam-dunk performance in 3D printed basketballs (yes, people practice real shots with them), PEBA brings the same bounce-back energy and durability to this lumbar cushion.

Here’s why PEBA rocks:

- Strength + Flexibility: With a tensile strength up to 30MPa, it’s tougher than TPU but still soft enough to hug your back like a cloud with muscles.

- Shockproof & Impact-Resistant: It won’t crack under pressure-literally. No breakage even under heavy impact.

- Temperature Warrior: From -40┬░C to +100┬░C, it keeps its cool (and shape). Whether you’re working in the Arctic or next to a volcano, your cushion’s got your back.

- Chemical & UV Resistant: Spilled your coffee? Left it in the sun? No problem-PEBA doesn’t care.

Why FacFox?

FacFox doesn’t just print stuff. We engineer comfort, optimize durability, and deliver future-forward products using advanced materials like PEBA. Whether you need a cushion, shoe insole, bike seat, or even a robot bumper (yes, really), we’ve got the tools, tech, and talent to make it happen.

Upgrade your support game with a lumbar cushion that’s stronger, smarter, and sassier than ever. Let PEBA and FacFox take your 3D printing needs to the next level.

Print strong. Sit smart. Choose FacFox.

Solution

- Step 1: Design Modeling. A digital 3D model of the lumbar support cushion was created using CAD software. The ergonomic grid structure was carefully designed to match the natural curve of the human spine and optimize flexibility, support, and breathability.

- Step 2: Slicing and Print Preparation. The 3D model was sliced into printable layers using slicing software. Parameters such as layer height, infill pattern, print speed, and support structures were configured specifically for PEBA material.

- Step 3: Material Loading. PEBA (Polyether Block Amide) filament was loaded into an FDM 3D printer. The filament was stored in a controlled environment to maintain dryness and ensure optimal print quality.

- Step 4: 3D Printing. The cushion was fabricated layer by layer using Fused Deposition Modeling (FDM) technology. The PEBA filament was heated, extruded through a precision nozzle, and deposited according to the sliced design. The unique grid geometry was printed with high accuracy to ensure dynamic support and structural integrity.

- Step 5: Cooling and Removal. Once printing was completed, the part was allowed to cool naturally to prevent warping. After cooling, the printed cushion was carefully removed from the print bed.

- Step 6: Post-Processing. Support structures, if any, were removed manually. The cushion surface was inspected for quality, and any minor imperfections were trimmed or polished to meet aesthetic and functional standards.

- Step 7: Quality Control. The finished product was subjected to thorough quality checks, including dimensional accuracy, structural integrity, flexibility, and rebound testing, ensuring the cushion met performance expectations.