- Customize Motorcycle Taillight Component with 3D Printing and CNC

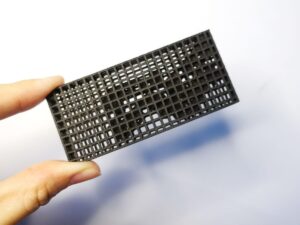

- CNC Machining SS304L Grill Grate Vent Cover

Gallery

About Project

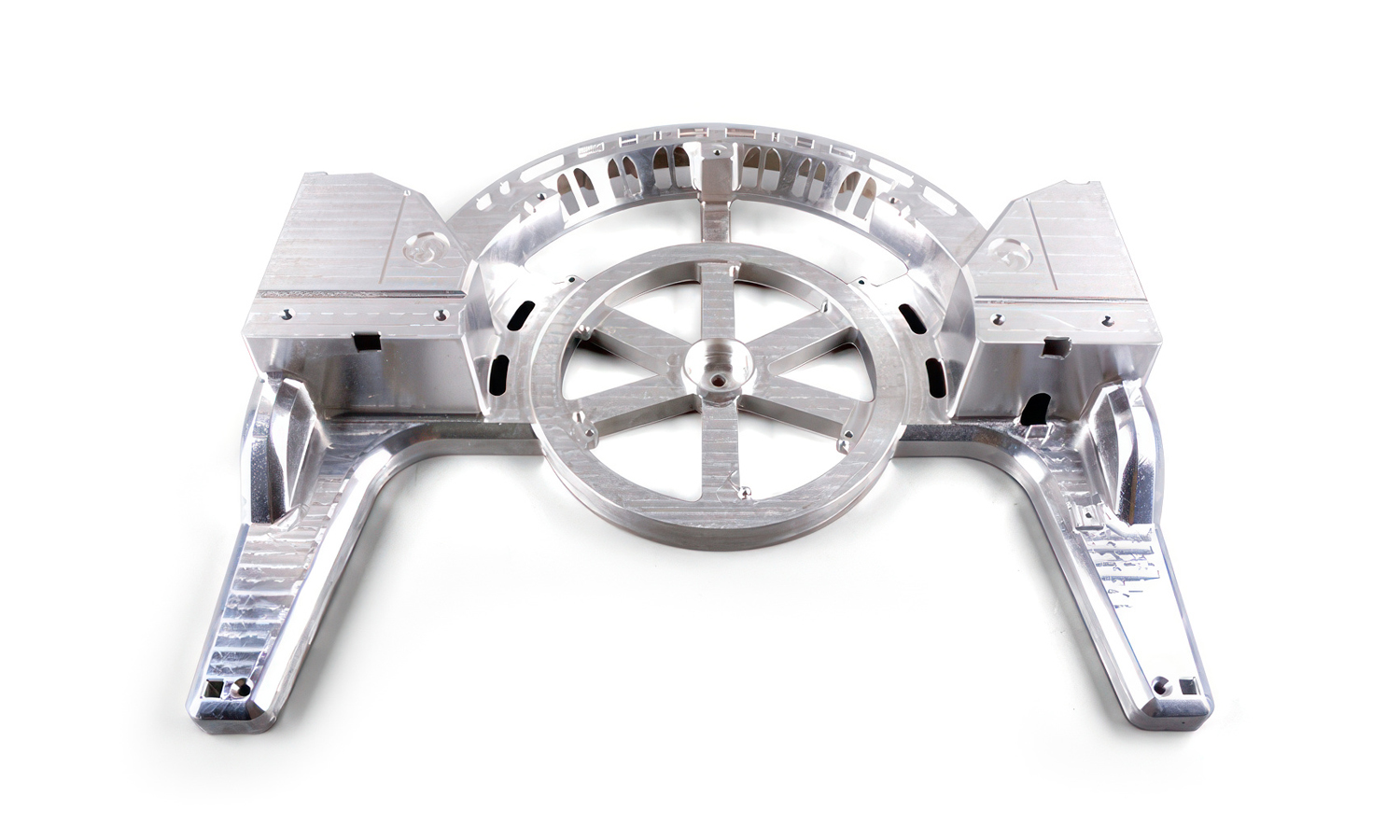

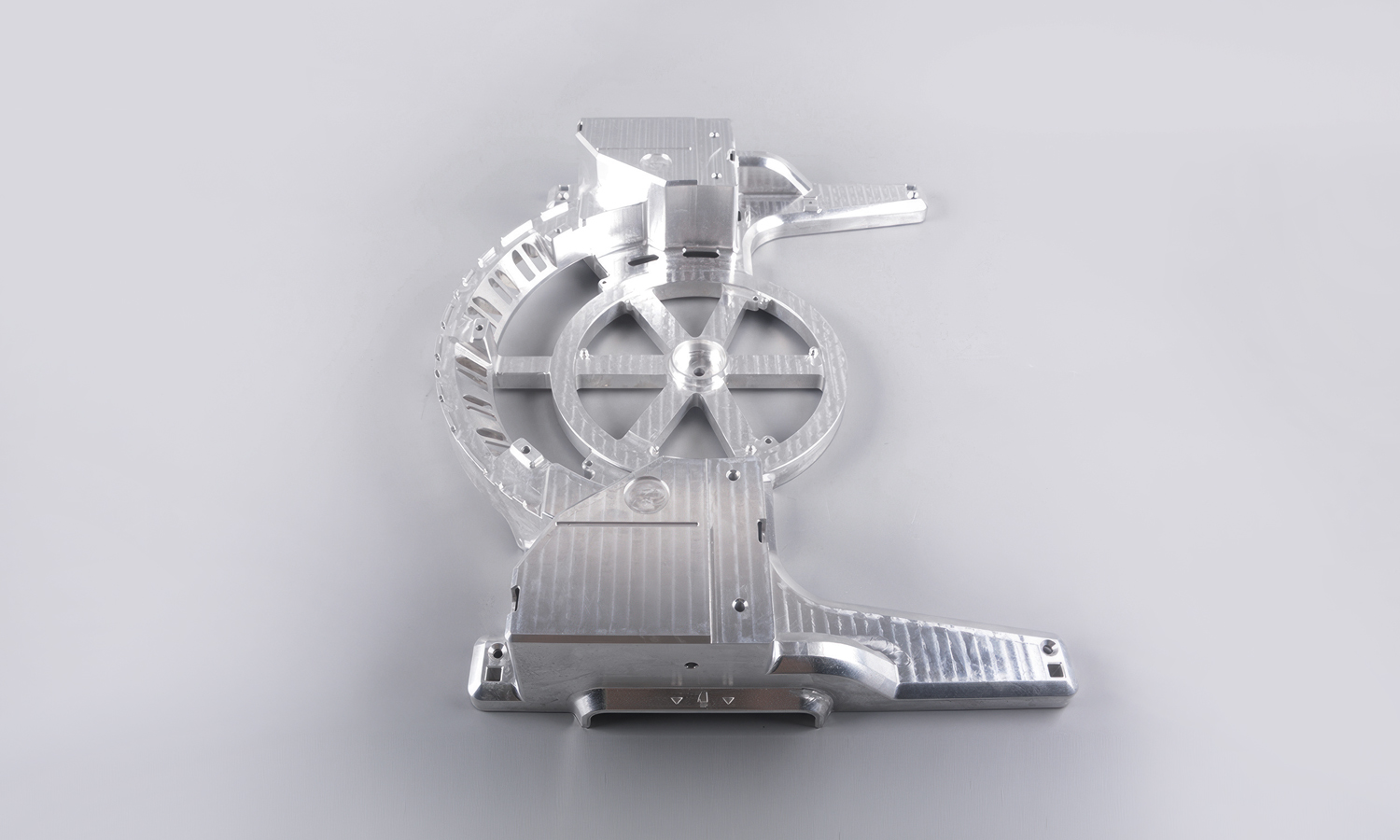

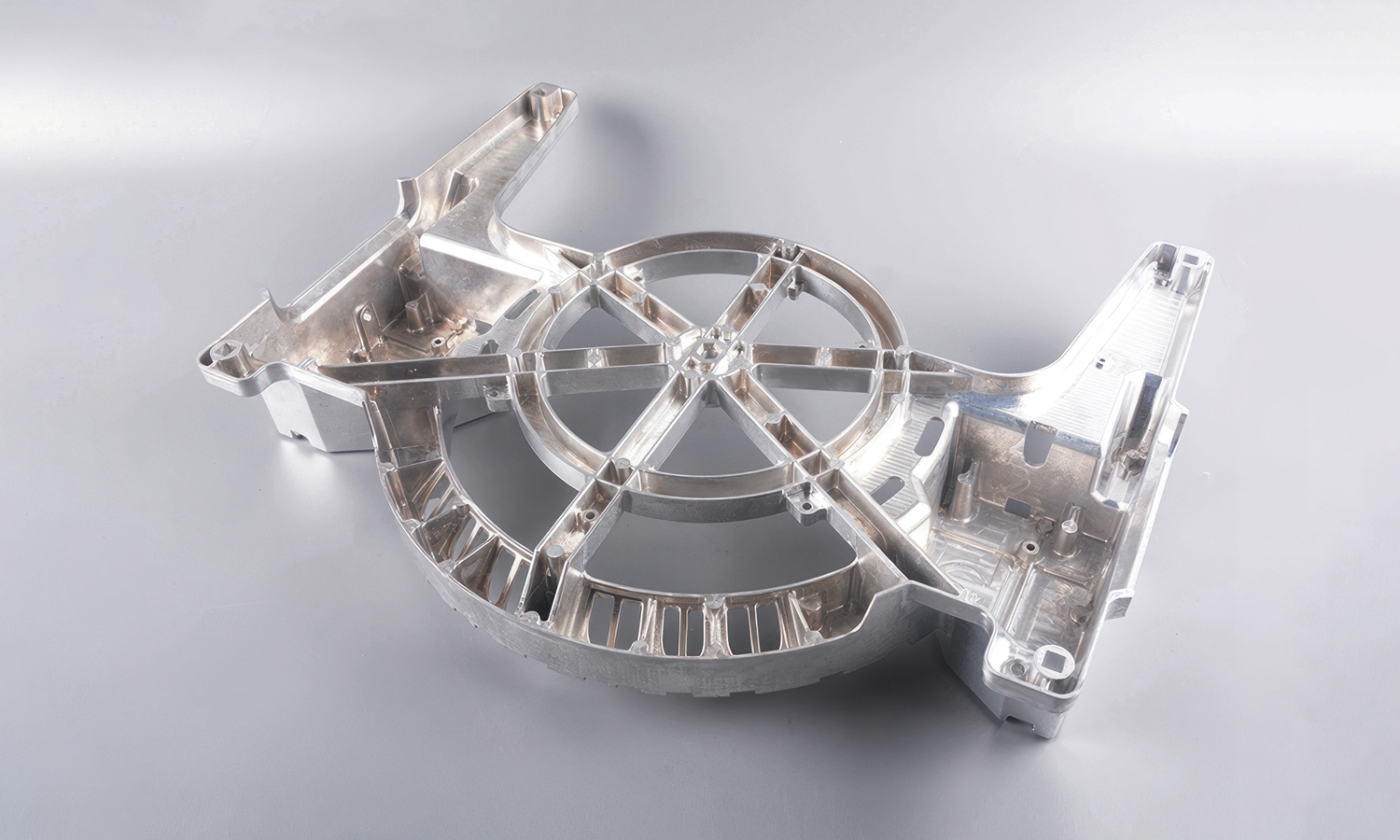

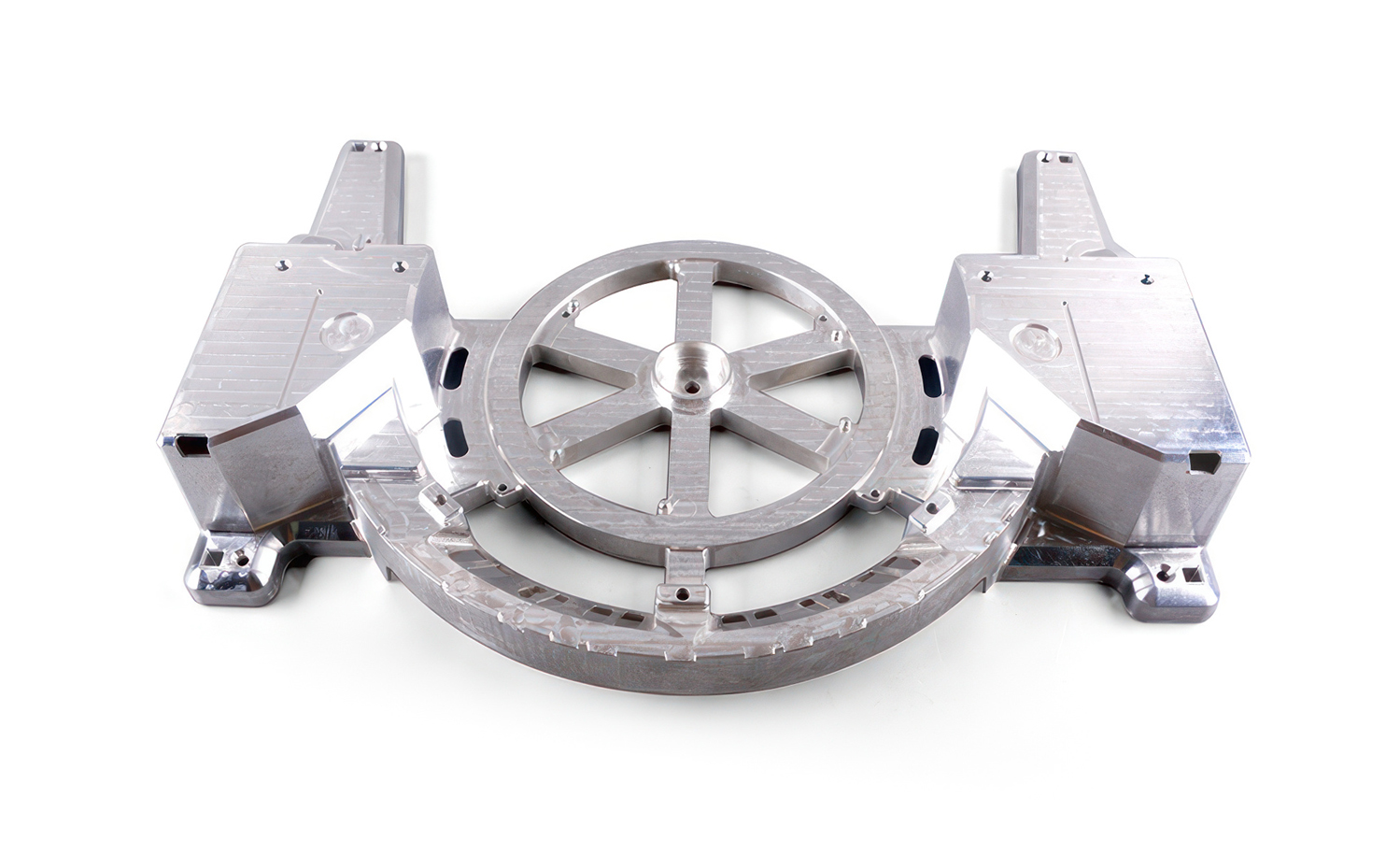

The base assembly of a compound miter saw is the unsung hero of precision cuts. It’s the stable foundation that ensures accuracy, supports the material, and houses critical mechanisms. For a component this vital, the choice of material and manufacturing process is paramount. That’s why CNC machining Al6061 aluminum alloy is an ideal solution for creating robust and accurate miter saw bases.

The part shown, with its intricate geometry, precise angles, and structural strength, perfectly exemplifies the capabilities of CNC machining. Al6061, a popular aluminum alloy, brings a host of benefits to this application:

- Exceptional Strength-to-Weight Ratio: Miter saws need to be sturdy yet manageable. Al6061 provides the necessary rigidity to withstand operational stresses without making the saw unduly heavy, enhancing portability.

- Superior Machinability: CNC machining thrives on materials that allow for precise material removal. Al6061 is highly machinable, enabling the creation of complex features, tight tolerances, and smooth finishes crucial for the accurate alignment of saw components.

- Corrosion Resistance: As a tool often used in various environments, good corrosion resistance is a significant advantage. Al6061 naturally forms a protective oxide layer, contributing to the longevity of the part.

- Durability and Reliability: The T6 temper of 6061 aluminum means it has undergone heat treatment, significantly increasing its strength and hardness, making it highly durable for the demanding conditions of a power tool.

Creating such a sophisticated part requires advanced manufacturing capabilities. From initial design to the final polished component, CNC machining ensures that every angle, slot, and mounting point is precisely replicated according to specifications. This precision is what translates into accurate cuts for the end-user, making the saw a reliable and effective tool.

When you require high-precision, custom metal parts like this compound miter saw base, FacFox offers expert CNC machining services that deliver superior quality and accuracy. Leveraging advanced machinery and a skilled team, FacFox can transform your designs into tangible, high-performance components, ensuring your products meet the highest standards of engineering and functionality. Partner with FacFox for reliable and efficient manufacturing solutions.

Solution

- Step 1: Material Selection and Preparation. An appropriate billet of Al6061 aluminum alloy was selected, ensuring it met the required specifications for strength and machinability. The raw material was then cut to a size slightly larger than the final part’s dimensions to accommodate machining operations.

- Step 2: CAD Model Generation and CAM Programming. A detailed 3D CAD (Computer-Aided Design) model of the compound miter saw base assembly part was created or received. Subsequently, CAM (Computer-Aided Manufacturing) software was used to generate toolpaths and NC (Numerical Control) code based on the CAD model, which would guide the CNC machine.

- Step 3: CNC Machining – Roughing Operations. The Al6061 billet was securely fixtured onto the CNC machine’s worktable. Roughing operations were performed using various cutting tools to remove large amounts of material quickly, getting the part close to its final shape while leaving sufficient material for finishing passes.

- Step 4: CNC Machining – Finishing Operations. Following the roughing, finishing passes were executed. Smaller and more precise cutting tools were utilized to achieve the specified dimensions, intricate features, smooth surfaces, and tight tolerances required for the base assembly part. This included the creation of the central circular element, spokes, mounting points, and other complex geometries.

- Step 5: Deburring and Edge Breaking. After the machining operations were completed, the part was carefully deburred. Any sharp edges or burrs resulting from the cutting process were removed to ensure safe handling, proper fit with mating components, and an aesthetic finish.

- Step 6: Quality Inspection. The manufactured Al6061 compound miter saw base assembly part underwent thorough quality inspection. Critical dimensions, tolerances, and surface finishes were verified using precision measuring instruments such as calipers, micrometers, and coordinate measuring machines (CMMs) to ensure compliance with the original design specifications.

- Step 7: Surface Treatment (Optional, but common). Depending on the specific requirements, the part may have undergone a surface treatment, such as anodizing. Anodizing would have been performed to enhance corrosion resistance, increase surface hardness, and/or provide a desired aesthetic finish.

- Step 8: Packaging and Shipping. Finally, the completed and inspected Al6061 compound miter saw base assembly part was appropriately packaged to prevent damage during transit and then prepared for shipping.