Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

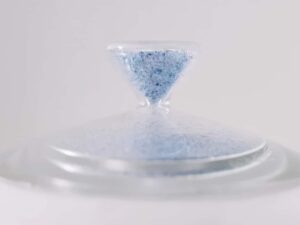

Imagine holding a perfectly weighted, elegantly designed set of cutlery in your hand. The smooth curves fit comfortably in your grip, and the sleek lines add a touch of modern sophistication to your dining experience. Achieving this level of ergonomic design and aesthetic appeal requires meticulous prototyping, and that’s exactly what we’ve accomplished with this set of 3D-printed resin cutlery.

This collection, featuring a large spoon, a small spoon, a knife, and a fork, showcases the power of Stereolithography (SLA) 3D printing for creating functional prototypes. The uniform gray color and consistent surface finish across all pieces immediately identify them as a cohesive set. This visual harmony is further reinforced by the matching design elements: each handle features a series of concentric rings, providing not only a unique visual signature but also a practical, textured grip. This consistent design language across all four pieces is crucial for creating a unified and professional product.

Beyond aesthetics, SLA printing delivers the dimensional accuracy and smooth surface finish necessary for tableware prototypes. Notice the fine details, from the delicate curve of the spoon bowls to the precisely defined tines of the fork. These details are critical for evaluating the functionality and ergonomics of the design. The smooth surface, achieved directly from the printing process, mimics the feel of finished cutlery and allows for accurate assessment of its tactile qualities.

This prototype demonstrates how 3D printing empowers designers to quickly iterate and refine their concepts. Imagine easily testing different handle designs, adjusting the balance of each piece, and even customizing the size and shape to perfectly suit specific needs. With rapid prototyping, the journey from digital model to tangible product is streamlined, accelerating the design process and ultimately leading to more innovative and user-centric tableware.

Are you looking to bring your tableware concepts to life? FacFox’s professional 3D printing services specialize in creating high-quality prototypes with exceptional detail and accuracy. From initial design visualization to functional testing, FacFox can help you realize your vision for the perfect cutlery set. Contact us today to explore the possibilities of 3D printed tableware prototyping.

Solution

- Step 1: A digital model was created using CAD software.

- Step 2: The model was then sliced into layers by specialized software.

- Step 3: Liquid resin was placed in a vat of the SLA 3D printer.

- Step 4: A laser beam was directed to selectively cure the resin, layer by layer, based on the sliced model data.

- Step 5: The build platform was lowered incrementally after each layer was cured.

- Step 6: The process was repeated until the entire cutlery set was formed.

- Step 7: The printed parts were removed from the resin vat.

- Step 8: Excess resin was drained and the parts were cleaned.

- Step 9: Support structures were detached from the cutlery pieces.

- Step 10: The surfaces were post-cured under UV light to achieve final strength and finish.

- Step 12: The cutlery pieces were inspected for quality and dimensional accuracy.