- SLA 3D Printed Realistic Black Panther Statue for Hamburger Shop

- LCD 3D Printed Resin Round Missile Silo Terrain Space Model

Material Plastic

Quantity 1 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

Step into the world of architectural elegance with our FDM 3D Printed Pagoda of Fogong Temple Scaled-down Model. This stunning replica captures the essence of the historic Chinese pagoda, known for its intricate design and cultural significance.

Structure and Features

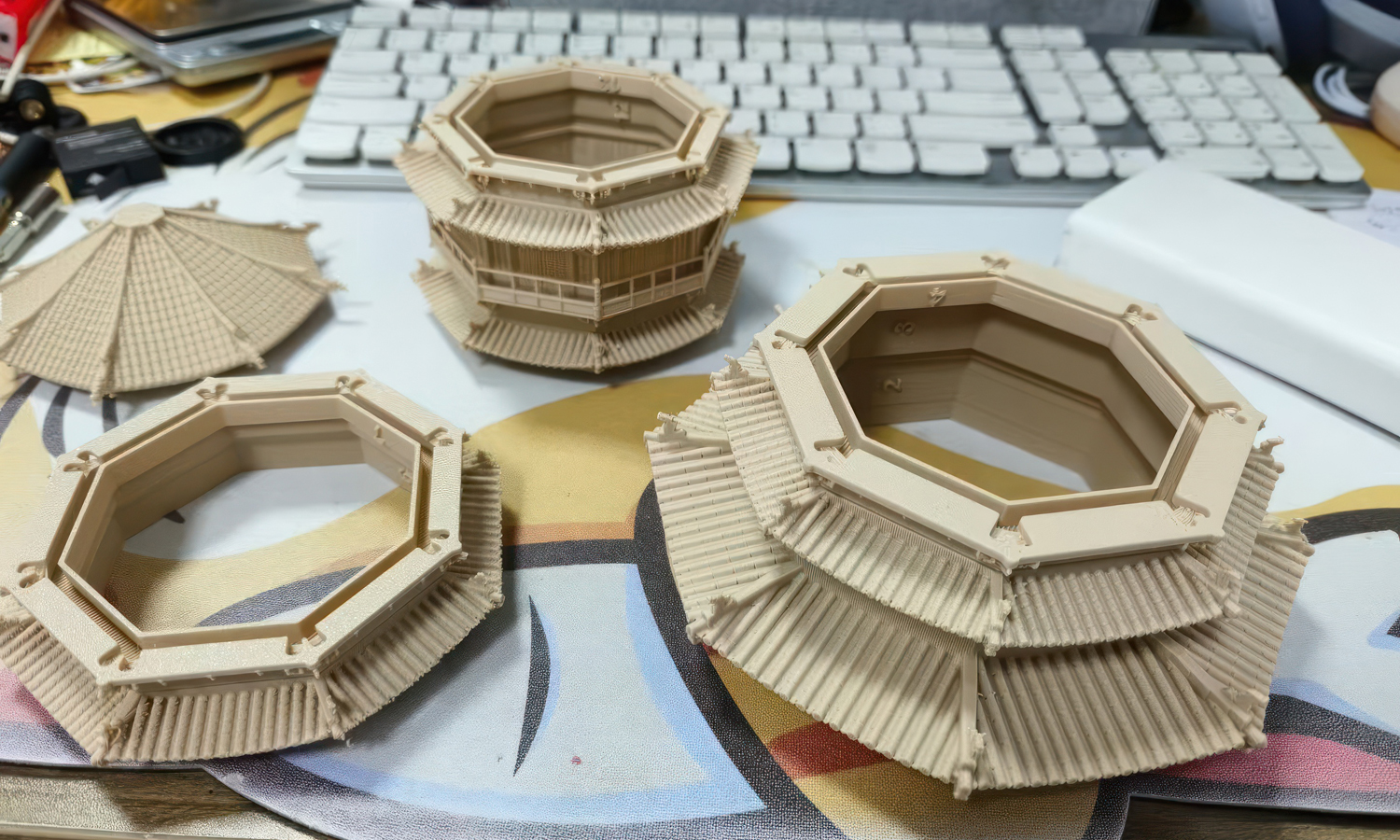

- Multi-Tier Design: The model accurately replicates the multi-tier structure of the original Pagoda of Fogong Temple. Each tier features distinct, gracefully curved roofs that highlight the architectural style of traditional Chinese pagodas.

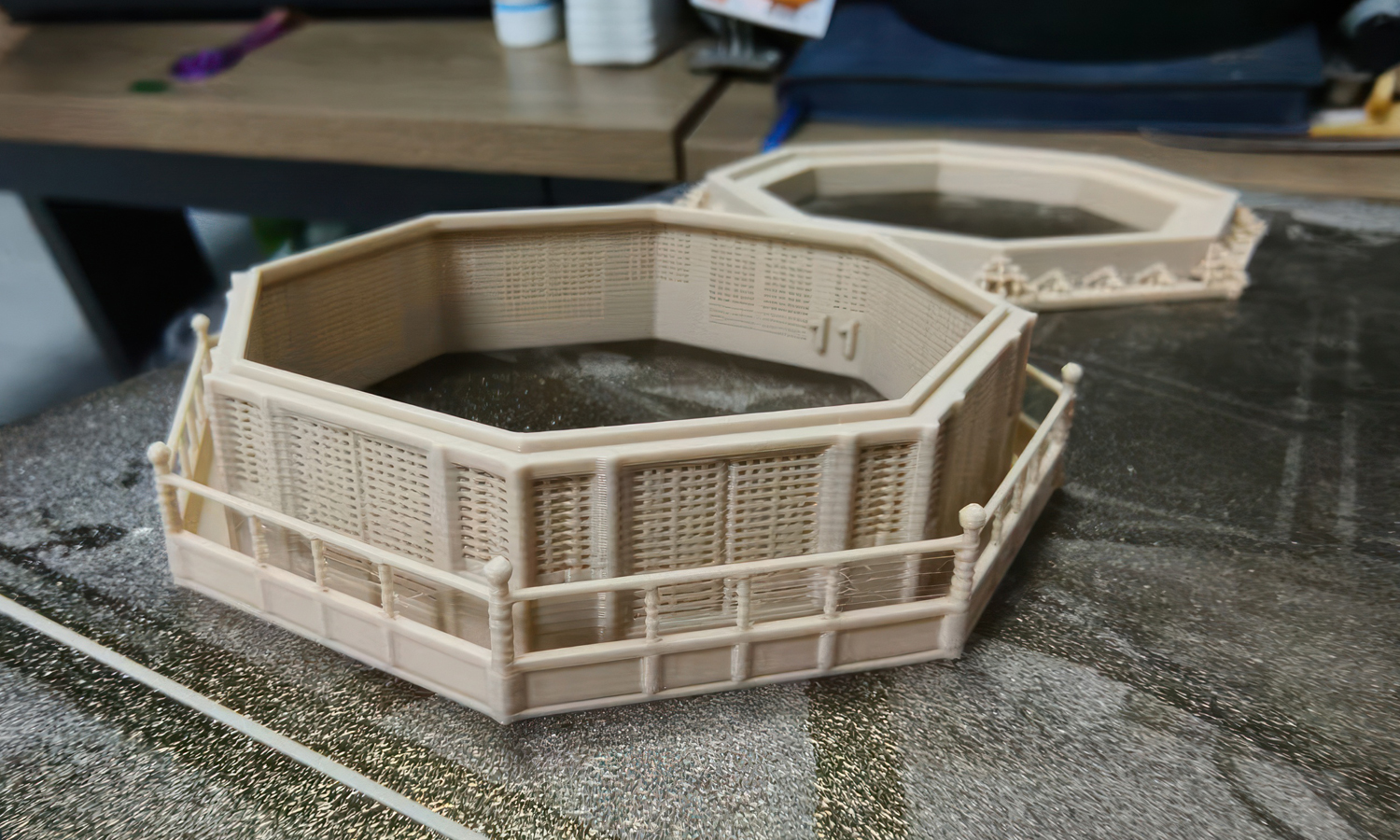

- Intricate Details: The lattice windows, railings, and fine engravings on each level showcase the intricate craftsmanship and attention to detail. The symmetrical patterns and precise elements reflect the historical and architectural significance of the temple.

- Octagonal Base: The model stands on a sturdy octagonal base, providing a strong foundation and enhancing its stability. The base is meticulously designed to mirror the original structure.

Appearance

- Wooden-Color Filament: To stay true to the original pagoda’s wooden construction, a wooden-color filament was chosen for this model. This gives the scaled-down replica an authentic and natural look, adding to its visual appeal.

- Smooth Finish: The surface of the model is smooth and well-finished, with minimal visible layer lines. The smooth appearance enhances the model’s realism and makes it a perfect piece for display.

Promote FacFox’s 3D Printing Service for Architectural Models

If you’re looking to create your own architectural masterpieces, we highly recommend FacFox’s 3D printing service. FacFox specializes in producing high-quality, detailed models with their advanced FDM 3D printing technology. Whether it’s for historical replicas, architectural prototypes, or custom designs, FacFox’s expertise and commitment to quality ensure that your models will turn out perfectly every time.

Discover the possibilities with FacFox and bring your architectural visions to life! ¤ī¤

Solution

- Step 1: Model Download. A 3D model of the Pagoda of Fogong Temple was acquired from a digital library, created using 3D modeling software, or obtained through 3D scanning of the actual structure.

- Step 2: Slicing and Preparation.┬ĀThe 3D model was then uploaded into a slicing software. Within the software, the model was strategically divided into four vertical sections to accommodate the printer’s build volume and the tall, slender structure of the pagoda. Optimal printing parameters, such as layer height, infill density, and support structures, were configured and the model was sliced into layers, generating G-code, the language used by the 3D printer.

- Step 3: Filament Loading.┬ĀA wooden-colored PLA filament spool was loaded into the FDM 3D printer. This filament was chosen to mimic the natural look of the historical pagoda.

- Step 4: Printing Process.┬ĀThe prepared G-code files for each of the four sections were sent to the 3D printer. The printer began the additive manufacturing process, layer by layer. Molten filament was extruded through a small nozzle and deposited onto the build platform, following the toolpath defined by the G-code. Support structures were printed simultaneously to provide stability for overhanging parts of the model, such as the eaves and roofs of the pagoda.

- Step 5: Cooling and Solidification.┬ĀAs each layer was deposited, it was allowed to cool and solidify, bonding to the layer below. This process was repeated until each of the four sections of the pagoda was completed.

- Step 6: Support Removal.┬ĀOnce the printing process was finished, the support structures were carefully removed from each section of the model.

- Step 7: Stringing Removal.┬ĀAny excess stringing (thin strands of plastic left behind during printing) was carefully removed using tools such as tweezers or a deburring tool.

- Step 8: Assembly.┬ĀThe four individual printed sections were then assembled, likely using adhesive, to form the complete pagoda model.