- Plan Ahead! View FacFox 2025 all-year Holiday Service Calendar Online!

- SLA 3D Printed Resin Rose Bag With Hinge Structure

Gallery

About Project

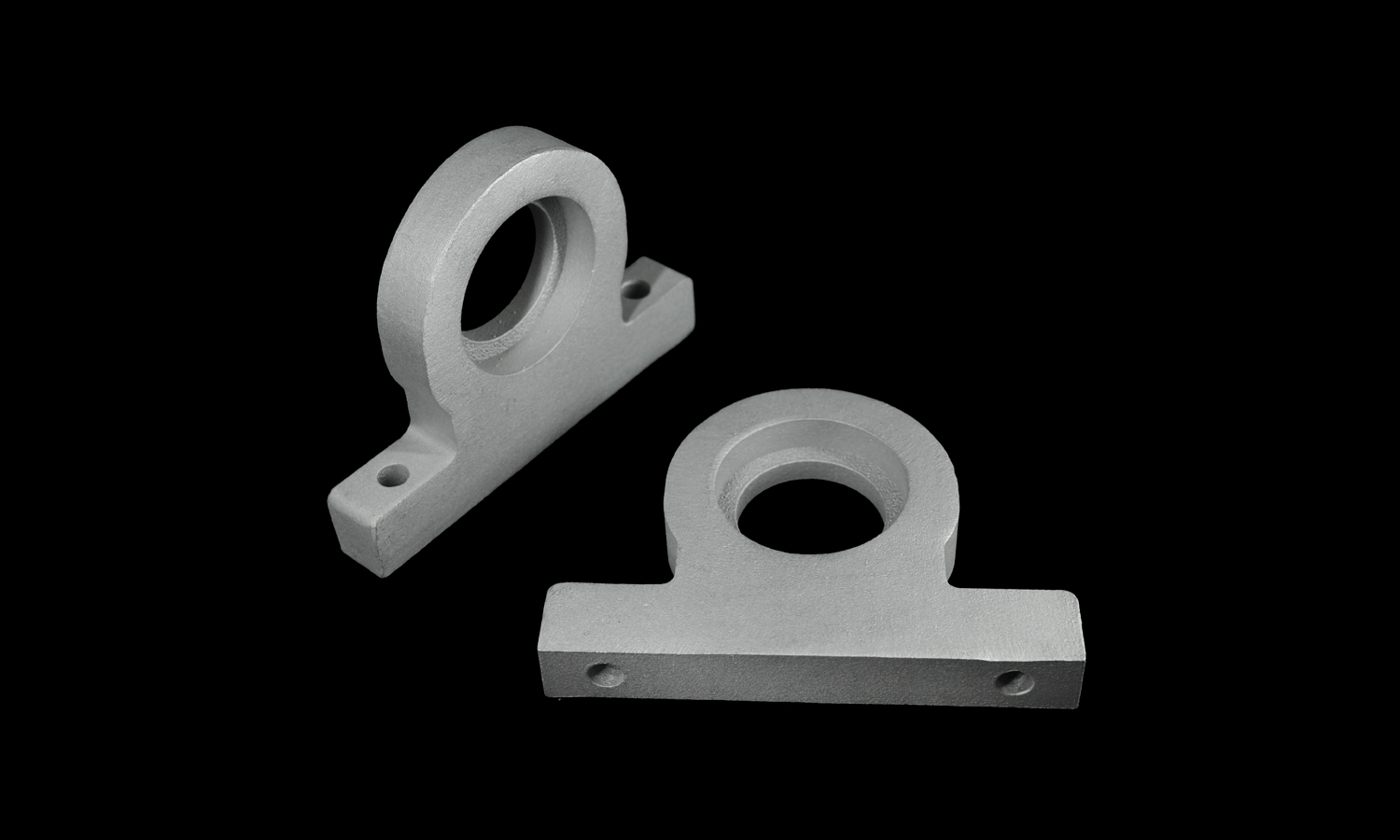

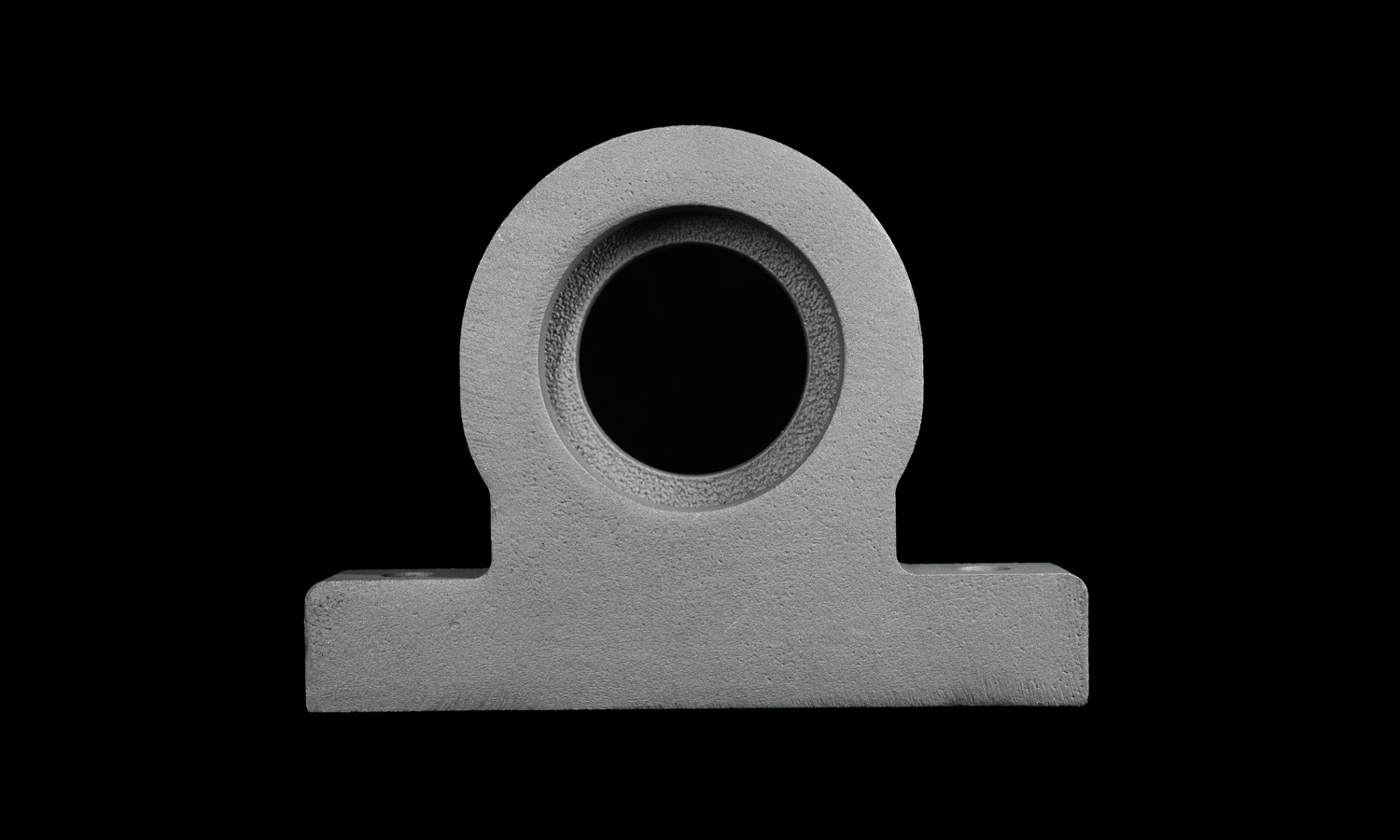

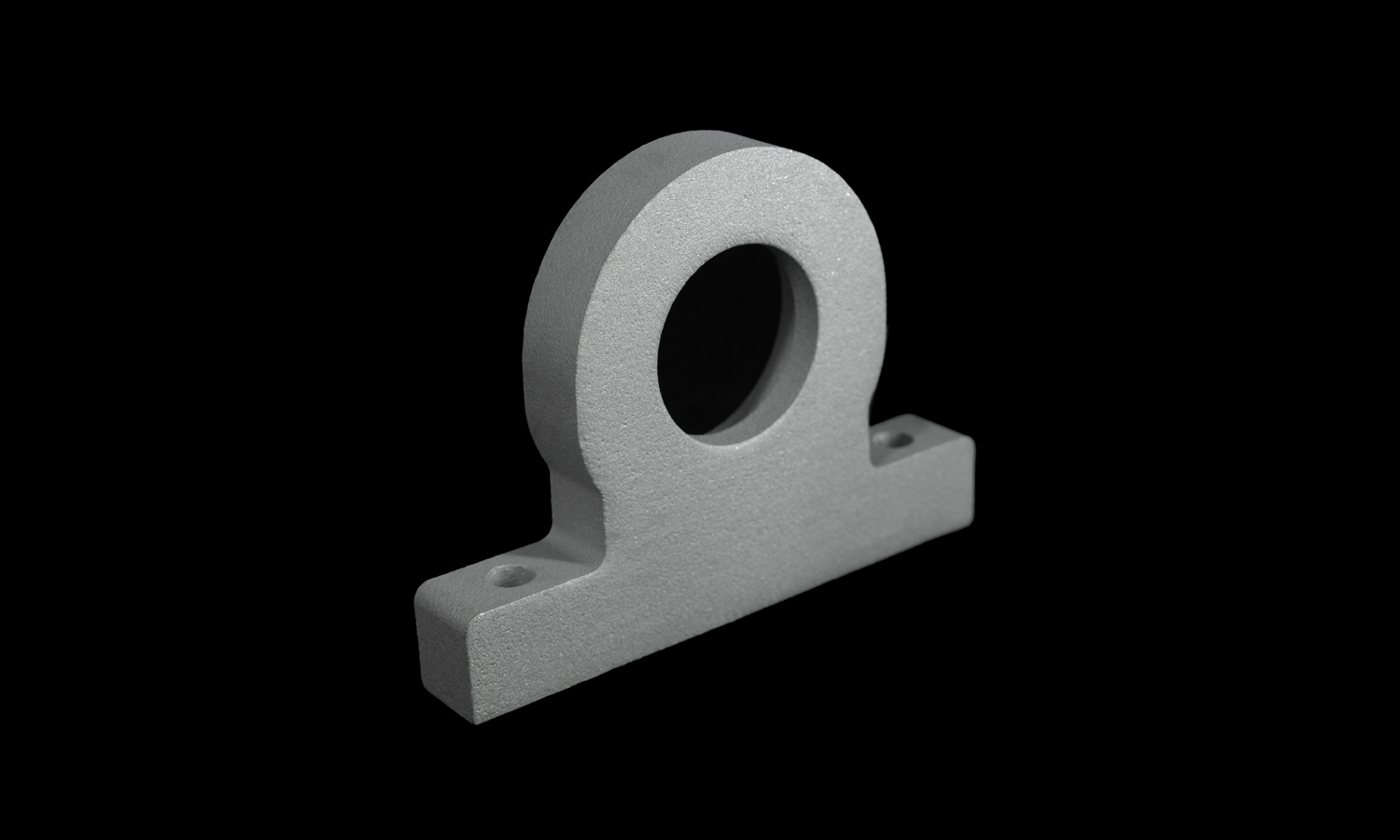

At the cutting edge of engineering and design, our Selective Laser Melting (SLM) 3D-Printed Aluminum Pillow Block Bearings offer the perfect blend of innovation and performance. With a commitment to precision and quality, these pillow block bearings are crafted to meet the stringent demands of modern mechanical applications.

Key Features:

- Material: Crafted from high-grade aluminum, known for its lightweight properties, excellent corrosion resistance, and robust strength. This makes it an ideal choice for diverse mechanical uses.

- Design: The bearing housing boasts a sleek, round design with a central opening perfectly designed to accommodate a rotating shaft. This ensures optimal support and friction reduction, leading to smooth and efficient operation.

- Finishing: The parts come with a raw finish, allowing for further customization and processing. We incorporate an allowance to the model, enabling our clients to achieve their desired dimensions and polish the surface to perfection. The unthreaded holes on the base plates provide flexibility for threading based on specific requirements.

Why Choose Our Pillow Block Bearings?

Our SLM 3D Printed Aluminum Pillow Block Bearings are engineered to support a variety of mechanical needs. Their primary function is to provide robust support for rotating shafts, reducing friction, and ensuring seamless movement. Whether used in industrial machinery, automotive applications, or other mechanical systems, these bearings deliver unparalleled performance and longevity.

Choose FacFox’s Metal 3D Printing Service

FacFox is at the forefront of metal 3D printing technology, offering unparalleled services to bring your designs to life with precision and efficiency. Our expertise in SLM 3D printing ensures that each part is crafted to the highest standards, tailored to your exact specifications.

From raw finishing to meticulous post-processing, we provide comprehensive solutions that cater to your unique requirements. Trust FacFox to deliver exceptional quality and innovative solutions that empower your projects. Explore the future of manufacturing with FacFox’s metal 3D printing services and elevate your mechanical designs to new heights.

Contact us today to learn more about how FacFox can transform your ideas into reality with our cutting-edge metal 3D printing capabilities!

Solution

- Step 1: 3D Model Creation. The initial design for the pillow block bearing was created using computer-aided design (CAD) software.

- Step 2: SLM 3D Printing. The 3D model was then processed for SLM 3D printing. A high-power laser beam was used to selectively melt and fuse layers of aluminum powder, building the bearing layer by layer according to the digital design.

- Step 3: Part Removal. Once the printing process was complete, the finished bearing was carefully removed from the build platform.

- Step 4: Support Structure Removal. Any support structures used during the printing process were removed from the bearing using appropriate methods.

- Step 5: Surface Finishing (Optional). Depending on the specific application, the bearing may have undergone further surface finishing processes, such as polishing or coating, to enhance its performance and appearance.