Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

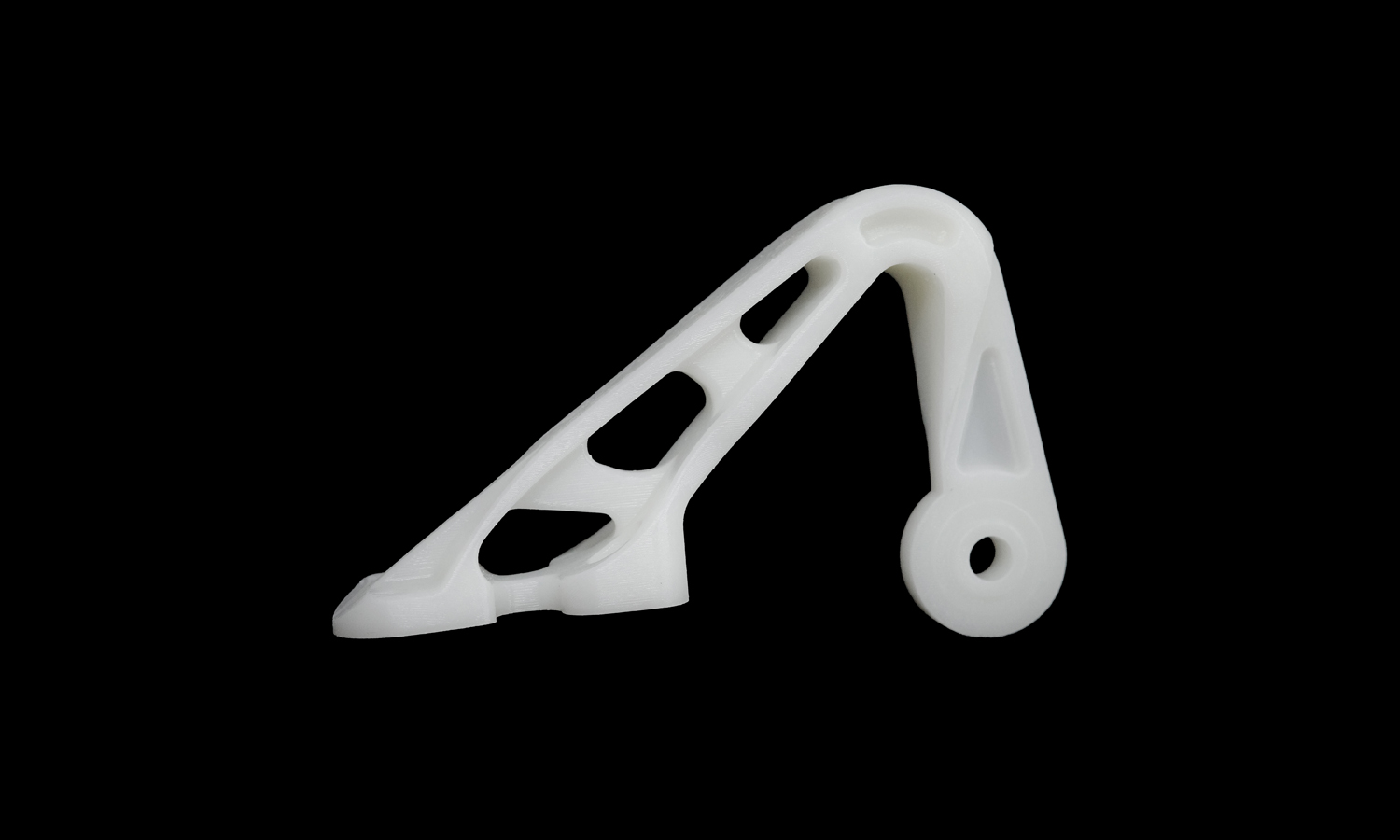

FacFox is proud to present our latest 3D-printed structural component, crafted using the high-performance Somos Ledo 6060 material. This part exemplifies the precision and quality achievable with our SLA (Stereolithography) 3D printing technology.

The showcased component is a meticulously designed structural part featuring multiple geometric cutouts. These cutouts not only reduce the weight of the part but also maintain its structural integrity. The smooth, white finish of the part highlights the exceptional surface quality and detail resolution that can be achieved with Somos Ledo 6060.

Somos Ledo 6060 is a versatile and durable material known for its excellent mechanical properties and fine feature detail. It is ideal for creating functional prototypes, end-use parts, and complex geometries that require high strength and precision. The material’s properties include:

- High tensile strength and elongation at break

- Excellent dimensional stability

- Smooth surface finish

- Good resistance to moisture and chemicals

At FacFox, we specialize in providing top-notch 3D printing services using advanced materials like Somos Ledo 6060. Our SLA 3D printing technology ensures that every part we produce meets the highest standards of quality and performance. Whether you need prototypes, functional parts, or intricate designs, FacFox has the expertise and technology to bring your ideas to life.

Choose FacFox for your next 3D printing project and experience the benefits of high-quality, reliable, and efficient manufacturing with Somos Ledo 6060. Contact us today to learn more about our services and how we can help you achieve your goals.

Solution

- Step 1: Design. A 3D model of the structural component with multiple geometric cutouts was designed.

- Step 2: File Preparation. The 3D model was prepared for SLA 3D printing by optimizing it for the printing process, ensuring proper orientation and support structures.

- Step 3: Material Selection. Somos Ledo 6060 resin was chosen for its high performance, excellent mechanical properties, and ability to achieve fine feature details.

- Step 4: Printing. The prepared 3D model was printed on an SLA 3D printer. A vat of Somos Ledo 6060 resin was used, and a laser selectively cured the resin layer by layer, building the component from the bottom up.

- Step 5: Support Removal. After printing, any support structures were carefully removed from the printed part.