Gallery

About Project

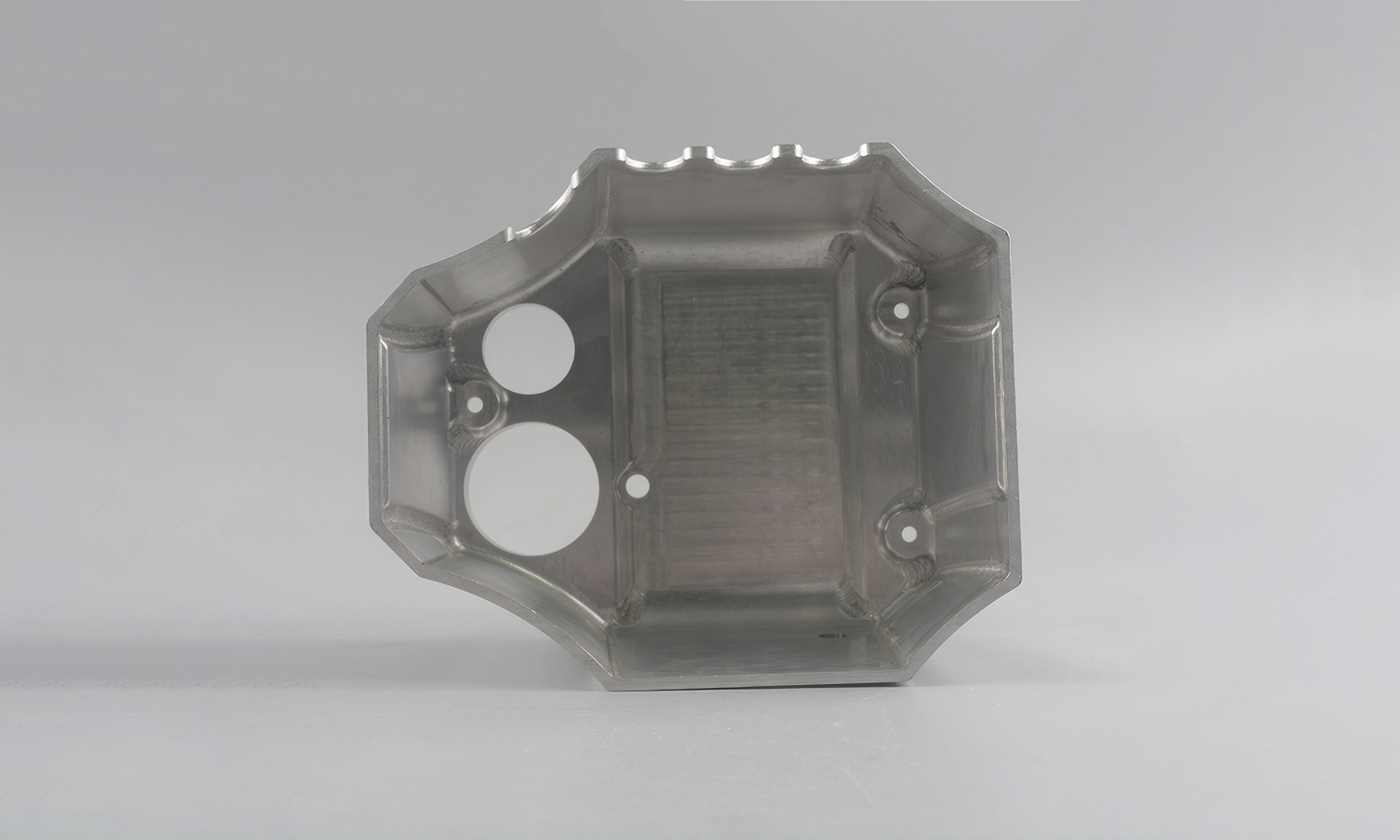

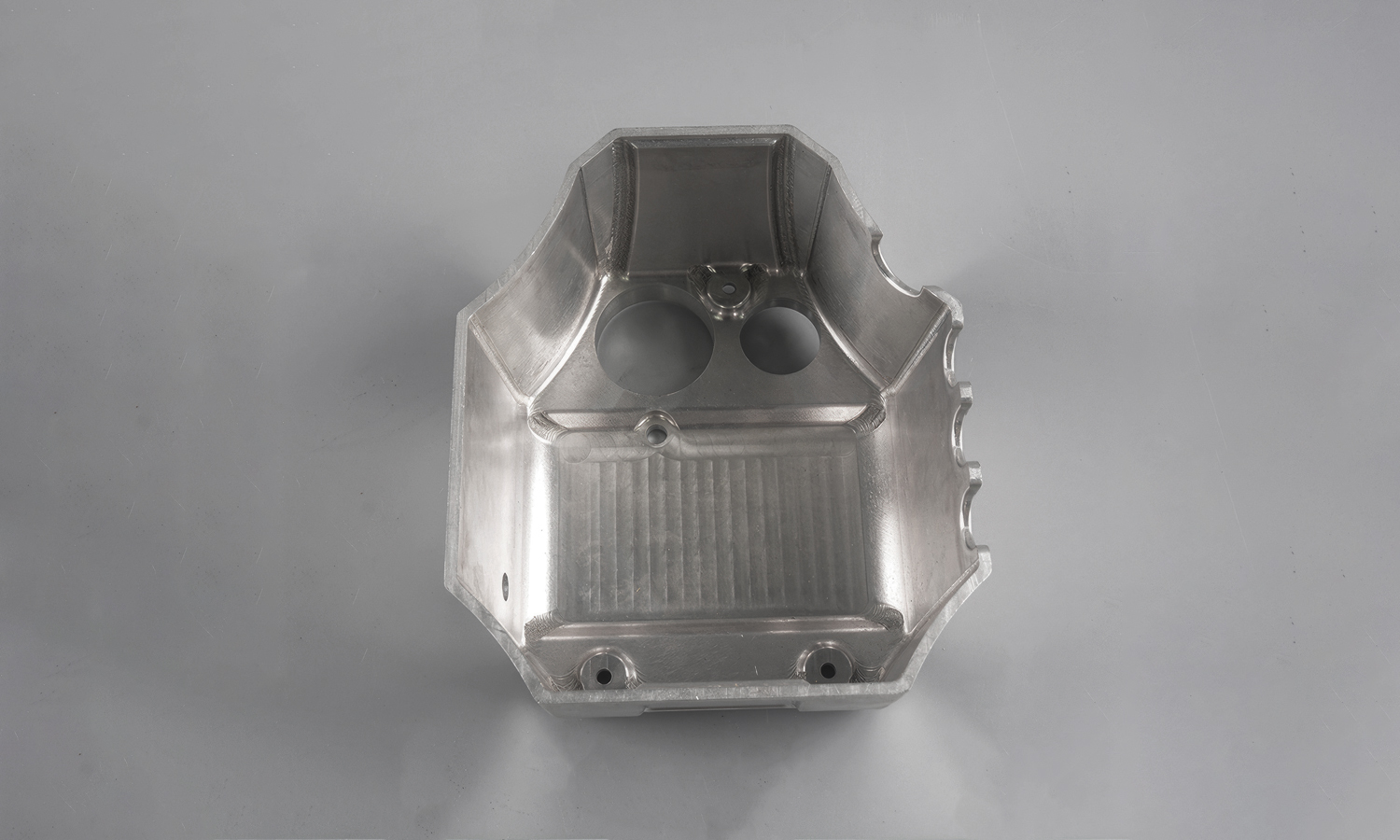

Introducing the CNC Milled Aluminum Alloy Machine Housing-a marvel of modern engineering crafted from high-grade aluminum alloy. This component showcases the epitome of precision, durability, and efficiency. Engineered to exacting specifications, it features a robust rectangular design with perfectly milled circular openings and parallel grooves that ensure optimal performance and structural integrity. The intricate bevelled edges and meticulously drilled screw holes highlight the superior craftsmanship and attention to detail.

Designed for industrial applications, this aluminum machine housing provides exceptional heat dissipation and structural reinforcement, making it indispensable in various mechanical and electronic assemblies. Its lightweight yet sturdy build ensures ease of integration without compromising on strength.

At FacFox, we specialize in delivering top-notch CNC milling services tailored to your specific needs. Our state-of-the-art machinery and skilled professionals guarantee precision and quality in every product, like our CNC Milled Aluminum Alloy Machine Housing. With a commitment to excellence and customer satisfaction, FacFox is your trusted partner for all your CNC machining projects. Explore our services and experience the FacFox difference today.

Choose FacFox for unparalleled CNC milling solutions.

Solution

- Step 1: The raw aluminum alloy material was procured and inspected for quality.

- Step 2: The material was cut to the required size using precision saws.

- Step 3: The cut pieces were clamped securely in the CNC milling machine.

- Step 4: The milling machine was programmed with the exact specifications for the housing component.

- Step 5: The aluminum pieces were milled into the desired shape, ensuring all holes and grooves were accurately cut.

- Step 6: The machined components were removed from the CNC machine and inspected for precision.

- Step 7: Any rough edges or burrs were removed using a deburring tool.

- Step 8: The components were then cleaned to remove any machining residues.

- Step 9: Final inspections were carried out to ensure all dimensions and specifications were met.

- Step 10: The finished aluminum alloy machine housings were packed and prepared for shipment.