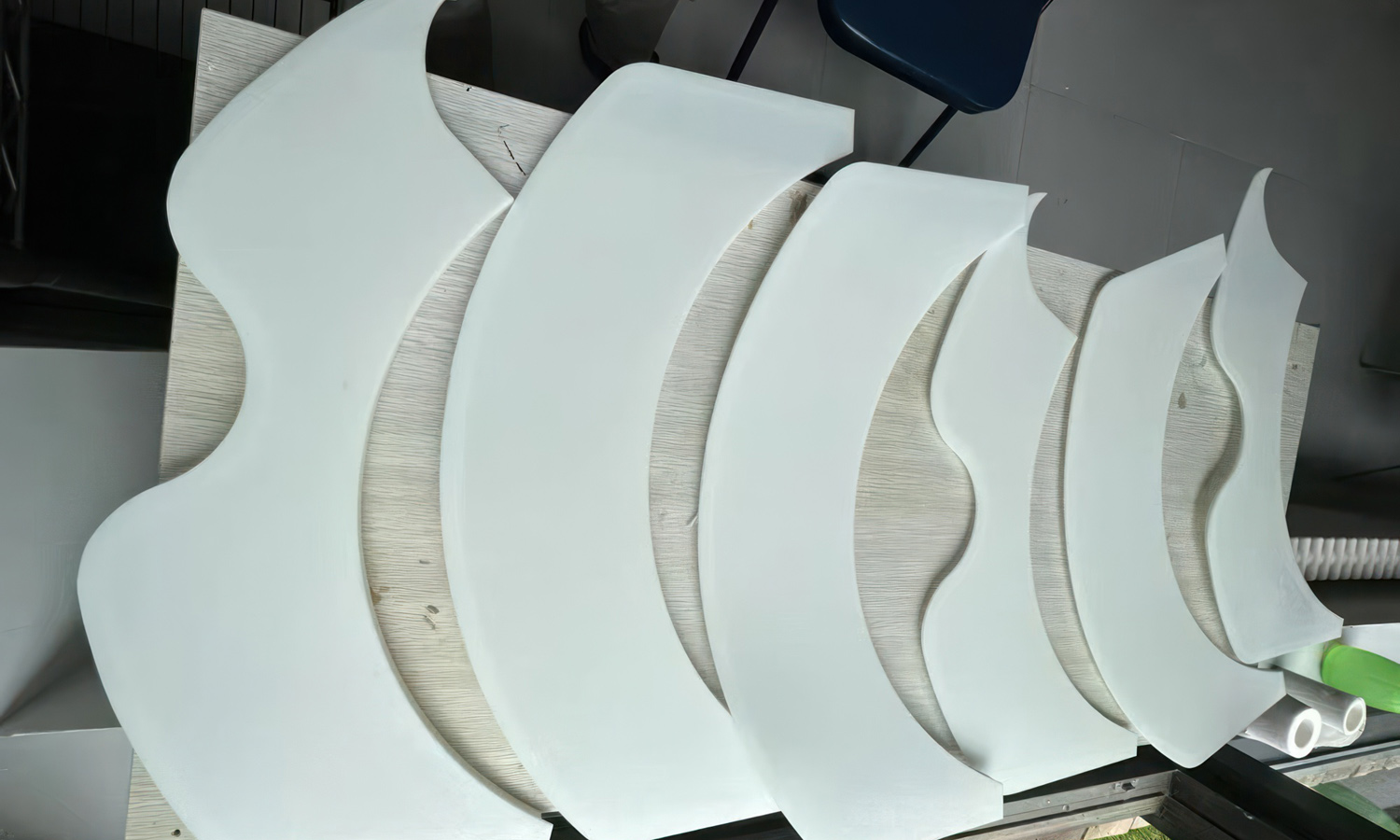

Material Resin

Quantity 6 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

Looking for pristine white resin boards with a sleek, curved design that resembles a blade? Look no further than FacFox’s top-tier Stereolithography Apparatus (SLA) 3D printing service!

We specialize in bringing complex shapes to life, and these white, blade-like boards are a perfect example. Their thin, curved design might seem simple, but achieving a smooth, flawless finish with this level of detail can be tricky. That’s where FacFox’s SLA 3D printing comes in.

Here’s what makes FacFox’s SLA printing perfect for your blade-like resin boards:

- Unmatched Precision: SLA printing offers incredible resolution, ensuring your boards boast razor-sharp curves and a truly blade-like aesthetic.

- Superior Smoothness: SLA printed resin produces an unparalleled smooth surface, ideal for white boards that demand a flawless finish.

- Complexities Made Easy: Don’t be fooled by the seemingly simple design. Our SLA technology tackles intricate details and thin geometries with ease.

FacFox: The Partner for Your Blade-like Board Printing Needs

At FacFox, we understand the importance of precision and quality. Our SLA 3D printing service is the perfect solution for bringing your vision of white, blade-like resin boards to life.

Ready to get started? Contact FacFox today and experience the difference SLA printing can make for your project!

Solution

- Step 1: Model Examination. A digital 3D model of the blade-like board was created, then examined and modified to meet the minimum printing requirements.

- Step 2: Resin Selection. High-quality white SLA Durable Resin was chosen specifically for its ability to deliver a smooth surface finish when cured.

- Step 3: Layer-by-Layer Printing. The digital model was then sliced into incredibly thin layers. A laser beam precisely cured each layer of resin onto a platform, meticulously building the board one layer at a time.

- Step 4: Support Structure Removal. Once the printing process was complete, the blade-like board was carefully separated from the build platform. Any temporary support structures added during printing were then meticulously removed.

- Step 5: Post-Processing. The board underwent a post-processing stage, which may have included washing to remove excess resin and potentially curing under UV light to ensure complete solidification.

- Step 6: Quality Control. Finally, the white, blade-like resin board underwent rigorous quality checks to ensure it met the desired specifications for dimensional accuracy, surface finish, and overall functionality.