Gallery

About Project

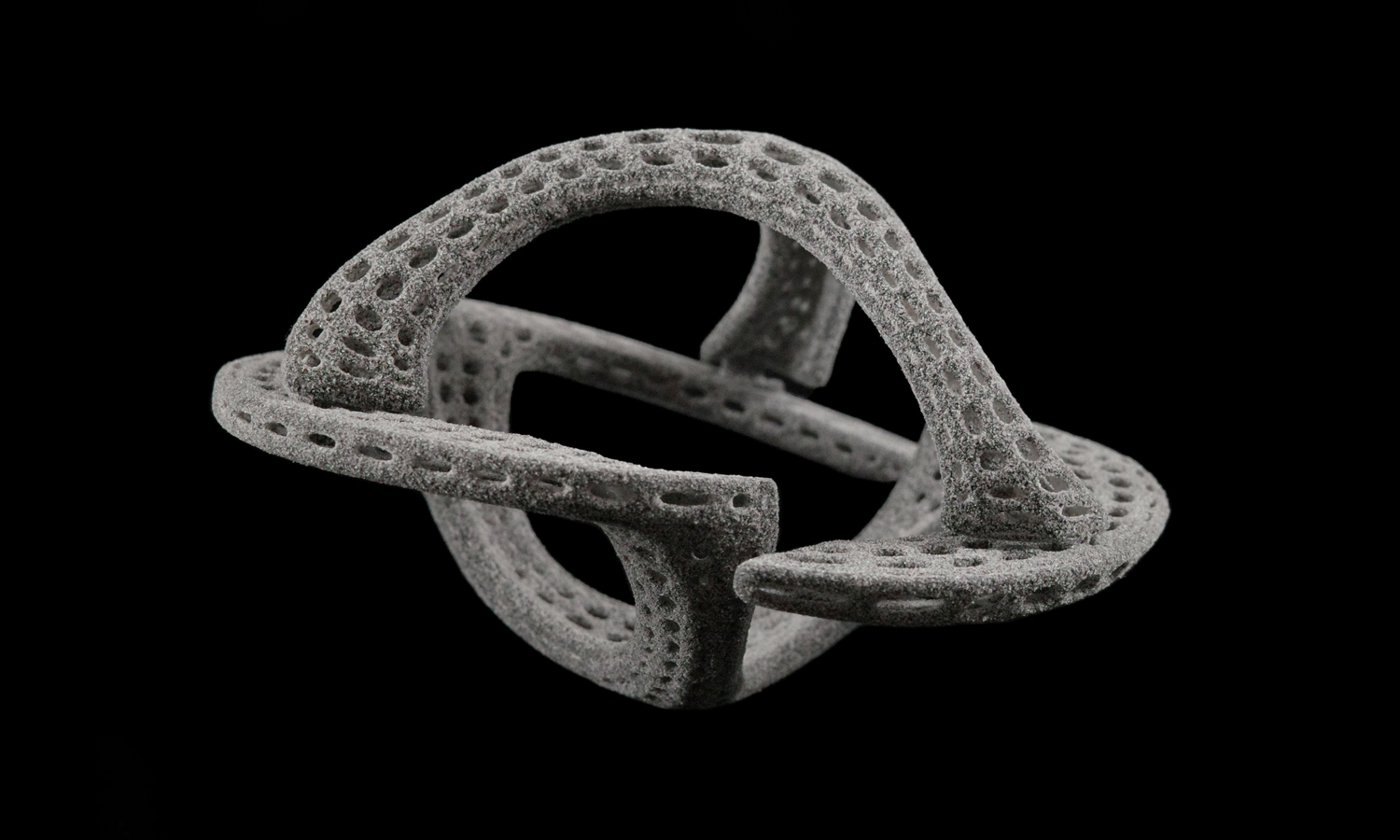

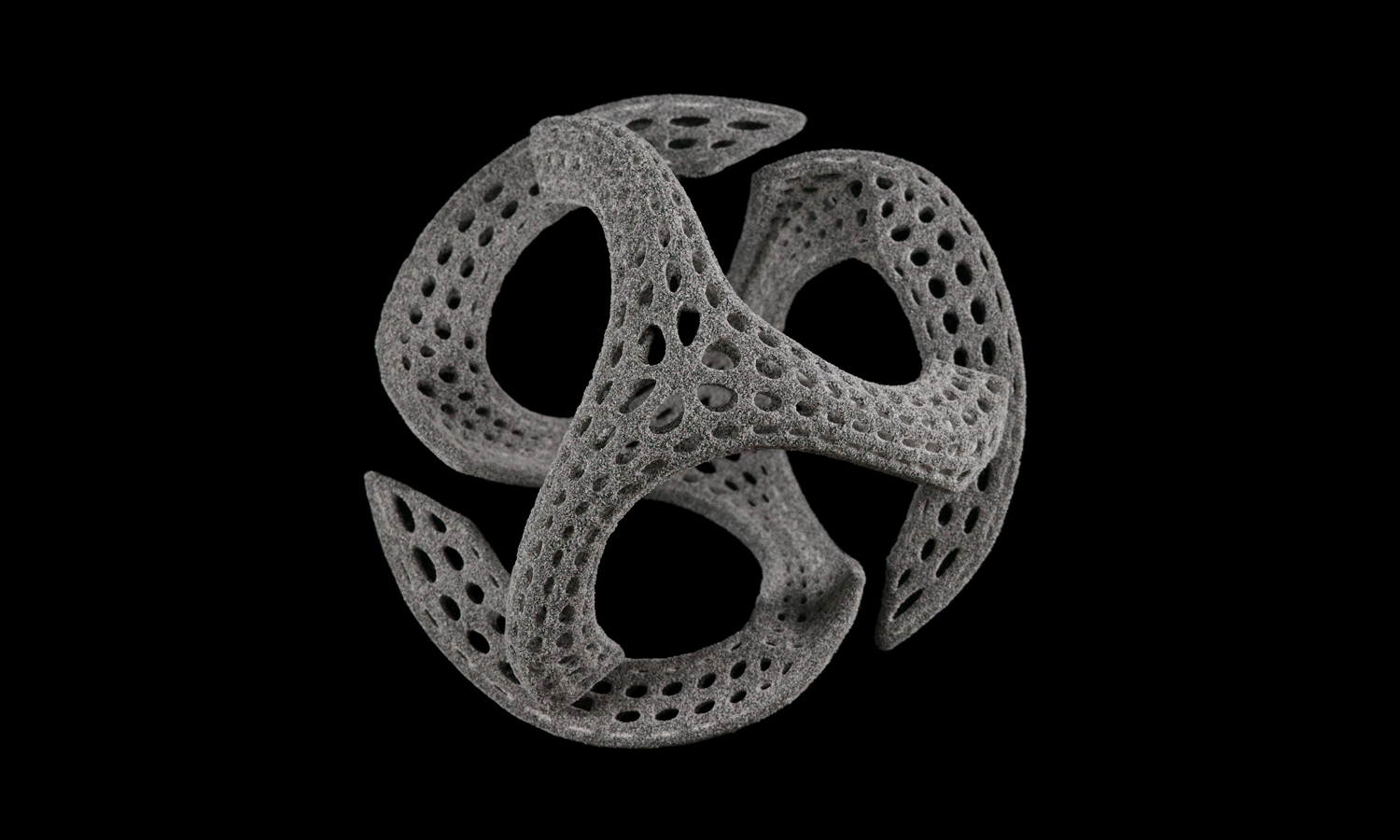

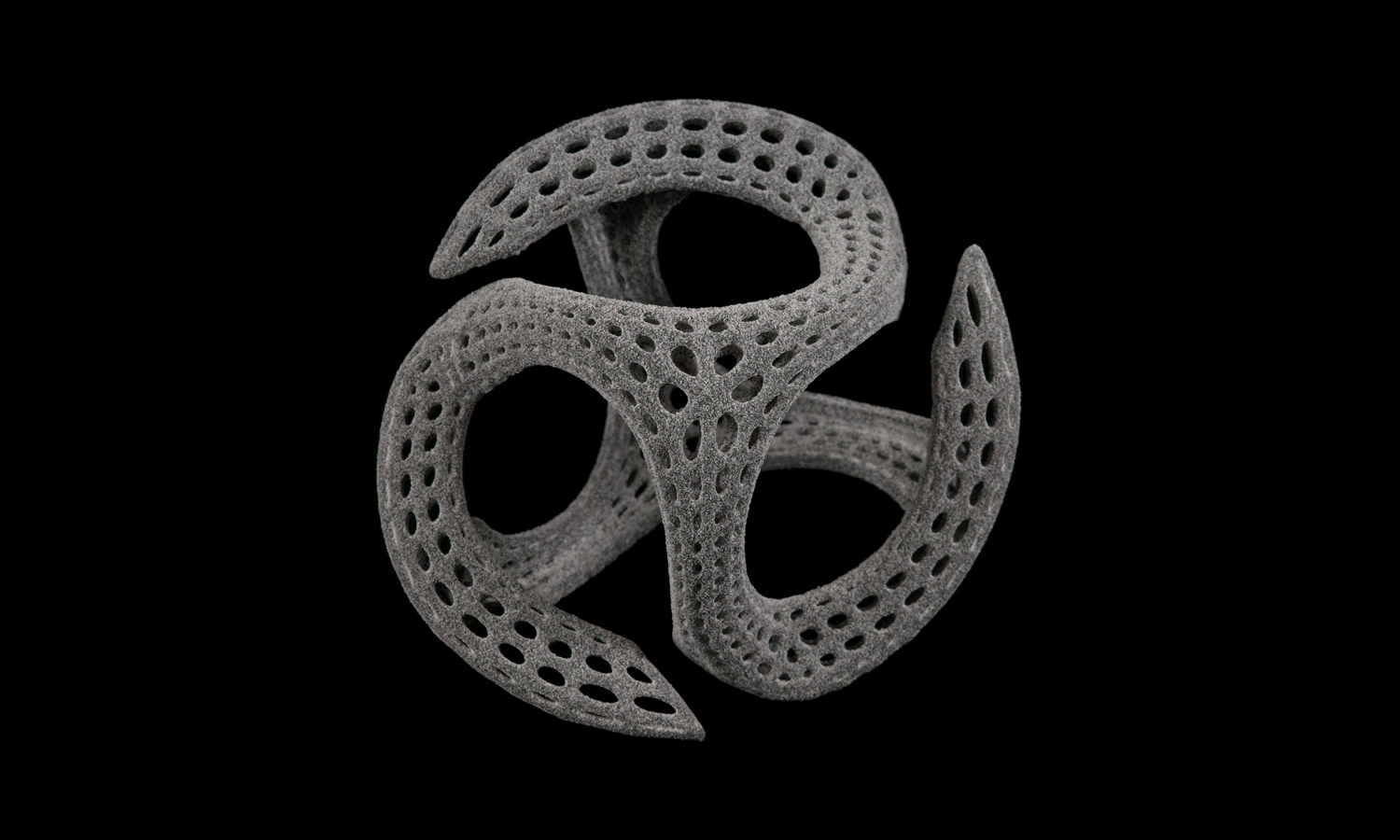

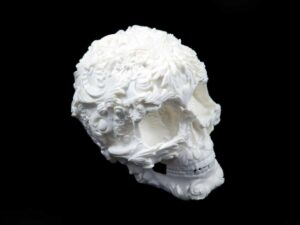

Imagine holding this captivating abstract flower that offers a unique tactile experience. With the advent of SLS (Selective Laser Sintering) 3D printing technology, this imaginative creation has become a reality.

Using the versatile and flexible material known as Thermoplastic Polyurethane (TPU), this flower embodies the perfect blend of artistry and functionality. SLS technology allows for intricate designs to be crafted, yielding hollowed structures with remarkable precision. The raw finishing showcases the grainy texture and dark grey color of the TPU material.

What sets this 3D printed flower apart is its squeezable nature, providing a surprising tactile sensation. Gentle pressure transforms the flower, allowing it to bounce back and take on different shapes, evoking a sense of wonder and interaction. The combination of delicate aesthetics and engaging tactility makes it a truly unique art piece.

Intrigued by this innovative creation? If you wish to explore the possibilities of SLS 3D printing and bring extraordinary designs to life, look no further than FacFox’s TPU printing services. With their state-of-the-art technology and expertise, FacFox can turn your vision into a reality. Whether you need to create functional prototypes, intricate patterns, or artistic masterpieces like the SLS 3D Printed TPU Squeezable Hollowed Flower, FacFox is your trusted partner.

Unlock the limitless potential of SLS 3D printing with FacFox today. Visit their website facfox.com to learn more about their TPU printing services and discover how they can help bring your wildest imaginations to life. Embrace the future of manufacturing and let your designs bloom with FacFox at your side.

Solution

- Step 1: Designing. The flower design was created using 3D modeling software, ensuring intricate details and hollowed structures were incorporated.

- Step 2: Preparing the 3D Printe. The SLS 3D printer was calibrated and prepared for printing, with the TPU material loaded into the printer’s reservoir.

- Step 3: Printing. The flower’s design was sliced into layers, and the SLS 3D printer selectively fused the TPU powder together, layer by layer, using a high-powered laser. This process repeated until the entire flower was formed.

- Step 4: Cooling and Cleaning. Once the printing was complete, the flower was allowed to cool, ensuring its structural integrity. Excess powder was then carefully removed using appropriate cleaning techniques.

- Step 5: Post-Processing. To achieve the desired raw finishing, the flower was left in its original state without additional surface treatment or polishing.

- Step 6: Quality Assurance. The final product underwent rigorous quality checks to ensure accuracy, strength, and overall aesthetic appeal.