- Mass Production DLP 3D Printed EPU Resin Sneaker Shoe Soles

- SS304 Bionic Mechanical Part Cast from SLA 3D Printed Resin Pattern

Material Resin, Metal

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

Topology optimization is a powerful technique that can help engineers design optimal shapes for mechanical parts, taking into account the material properties, the applied loads, and the boundary conditions. However, creating these optimized parts can be challenging, especially if they have hollow or overhanging structures that are difficult to produce with conventional methods.

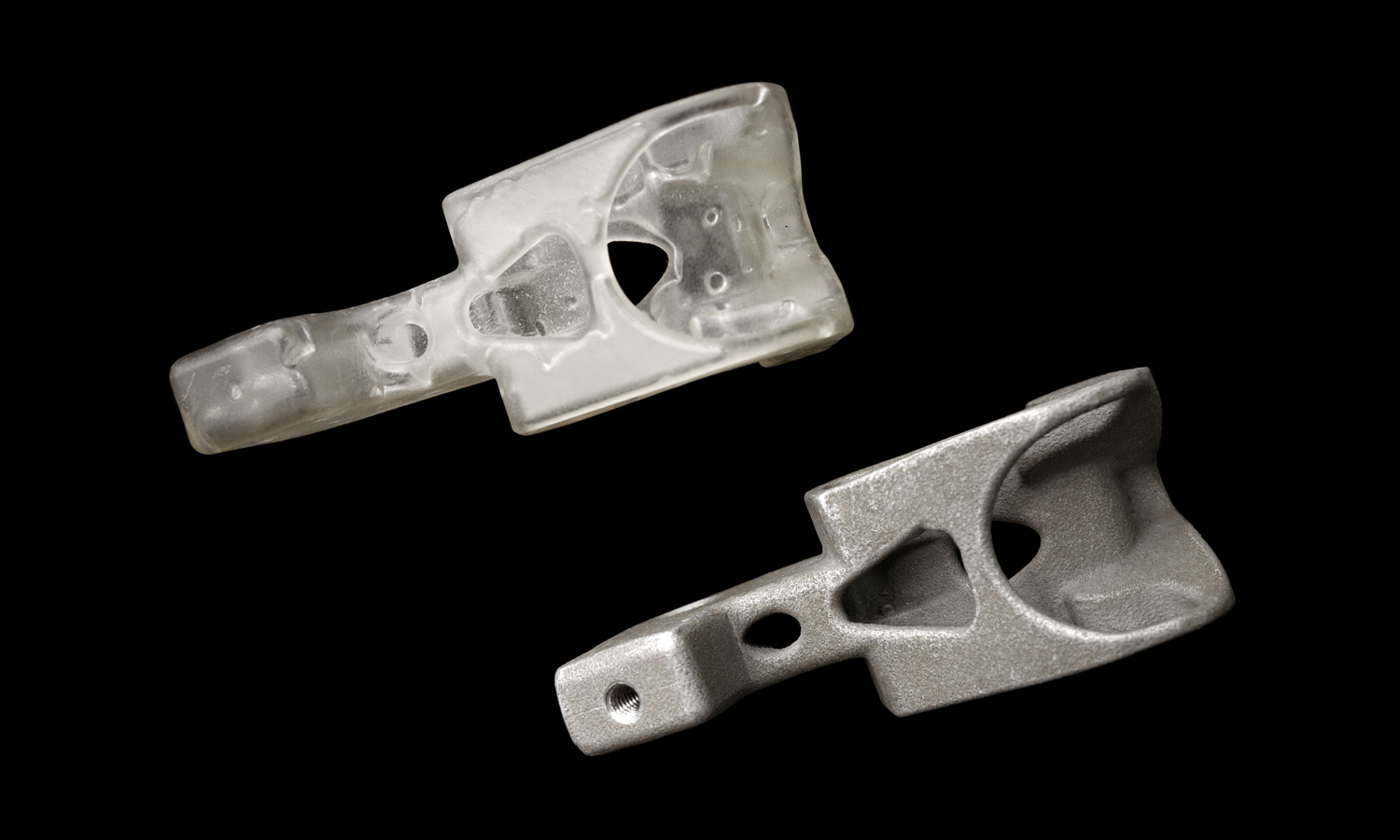

One solution to this problem is to use 3D printing and casting to create the topology optimized parts. This approach involves printing a hollowed resin pattern of the part using a SLA 3D printer, and then casting the part with aluminum. The resin pattern is made from a special castable resin called Somos Element, which is formulated for SLA 3D printers and offers excellent dimensional stability, accuracy, and surface finish. The pattern is then placed in a ceramic shell mold and heated to melt out the resin. The resulting cavity is then filled with molten aluminum to create the final metal part.

At FacFox, we use Somos Element to print the hollowed resin pattern of the topology optimized mechanical part. We also use software to process the 3D model of the casting pattern into a hollow structure, which greatly reduces the consumption of resin raw materials and saves a lot of cost. This process virtually eliminates resin expansion during post-processing and significantly reduces the amount of ash left over from the pattern removal step.

When the client specifies the size and material of the part they want, we enlarge the casting pattern based on our experience about the metal’s shrinkage rate. Also, the part needs chamfering to remove any sharp edges or burrs. We use advanced tools and techniques to ensure that the final metal part meets the client’s specifications and expectations.

If you are interested in creating your own topology optimized metal parts using 3D printing and casting, you can contact FacFox for a quote and consultation. We offer professional and affordable manufacturing services for various industries and applications, using advanced technologies and quality materials. You can upload your 3D model to our website facfox.com and choose from a range of options for materials, finishes, colors, and quantities. You can also browse our portfolio of previous projects via facfox.com/case/ to see some examples of our work. We will deliver your parts to your doorstep with fast turnaround time and excellent customer service.

Solution

- Step 1: A 3D model of the topology optimized mechanical part was created using computer simulation, taking into account the material properties, the applied loads, etc.

- Step 2: The 3D model of the casting pattern was processed using software to create a hollow structure, which reduced the consumption of resin raw materials and saved a lot of cost, also decrease the ashes. The model was also chamfered to remove any sharp edges or burrs.

- Step 3: The hollowed resin pattern was printed using a SLA 3D printer, which used a laser to cure liquid resin into solid layers. The resin used was Somos Element, which was a special castable resin that offered excellent dimensional stability, accuracy, and surface finish.

- Step 4: The resin pattern was placed in a ceramic shell mold and heated to melt out the resin. The resulting cavity was filled with molten aluminum to create the final metal part.

- Step 5: The metal part was removed from the mold and finished with trimming and cleaning.