Sheet Metal Fabrication Services

Sheet metal prototypes and low-volume production parts shipped in as fast as 2 days

Overview: How Sheet Metal Fabrication works?

The Basics Of Sheet Metal Fabrication

Sheet metal fabrication is the process of forming a piece of metal into a desired shape through bending, stretching, and removal of material. At Rapid, we use press brake punches and die tooling to bend and stretch flat stock into its final geometry. The sheet metal prototyping process is most often used when form, fit, and function are all a priority.

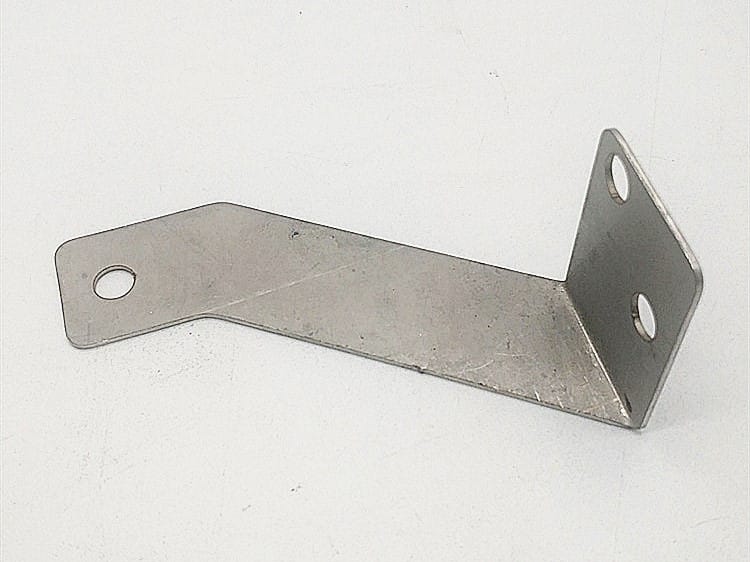

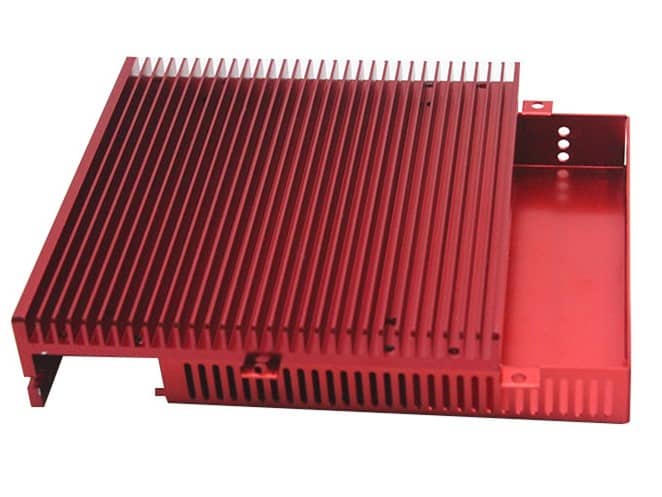

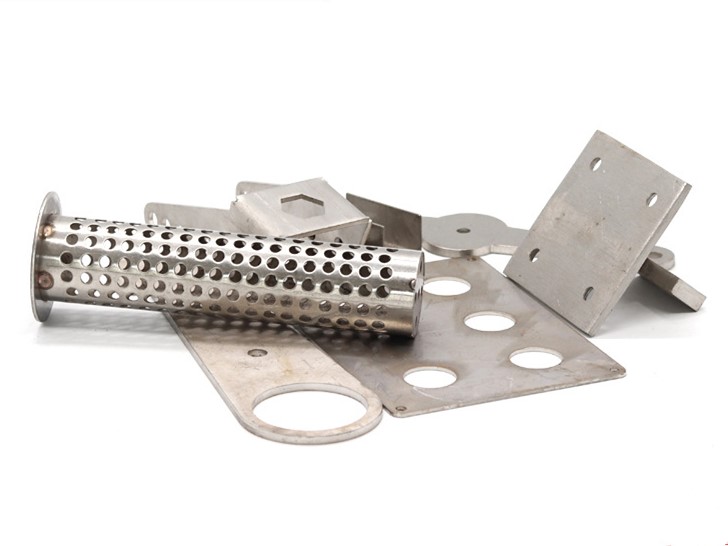

Typical sheet metal parts we manufacture include enclosures, brackets, assemblies, weldments, cabinets, and other components. Whether you need a single sheet metal part or 20 parts, we have the capacity to produce your sheet metal prototypes fast.

Benefits of Sheet Metal Fabrication With FacFox

FacFox offers metal fabrication and welding from prototype phase to product-ready parts. This means your project can be cut, formed, and welded in house, saving you the hassle of working with several shops. As part of our commitment to quality, we provide documentation and traceability for materials certification, materials inspection, and machine calibration. In other words, everything you need for a successful end result.

Features of Sheet Metal Fabrication

Advantages

Drawbacks

Sheet Metal Fabrication Processes

CNC laser technology allows us to manufacture parts quickly and cost-effectively while maintaining the highest quality standards. Custom Sheet Metal Braking (forming/bending) services for laser cut parts, provides precision bending results coupled with superior repetition accuracy. The sheet metal punching machines use punches that pass through the sheet metal, to realize accurate holes and error-free.Laser Cutting

Forming (Bending)

Sheet Punching

Tilting waterjet head with 4 or 5-axis CNC control, cuts more than 4ŌĆ│ sheet/plate metal Welding two pieces of metal together forms a permanent bond in which the metals are heated to a melting point, mixed together and then cooled, creating a single object. This type of bond is stronger than other bonds, such as soldering, which can be reversed. Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.Water Jet Cutting

Welding

Plasma Cutting

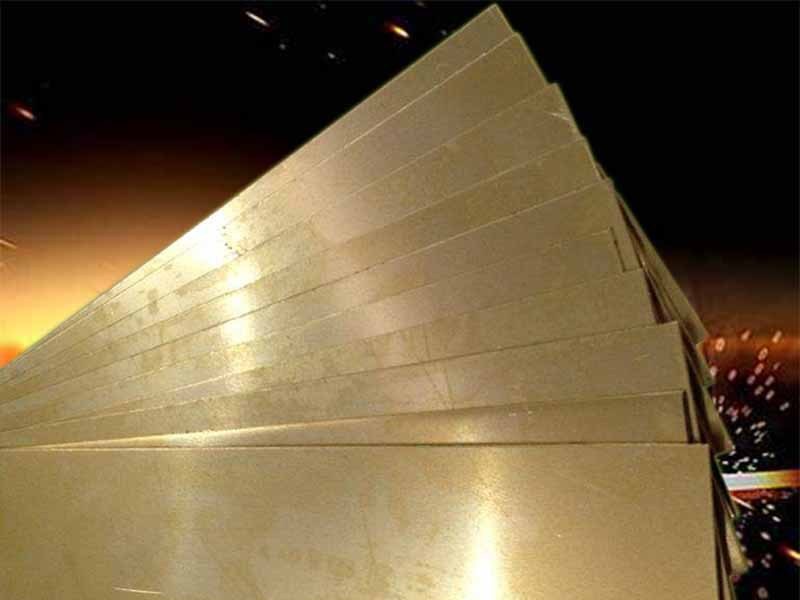

Available Materials

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in coating and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts.

- Electroplating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

Sheet Metal Fabrication Applications

Whether you need a bracket, chassis, enclosure, or any other complex sheet metal design, weŌĆÖll ship 1 to 50+ prototypes in as fast as 4 days. Get the same great service of our prototyping shop higher volumes. Our low-volume production facility can produce up to 50 to 1,000+ sheet metal parts in as fast as 10 days. We provide a partial or complete prototype assembly in 2 to 3 weeks. We help coordinate the procurement of your custom and catalog parts to build your electro-mechanical assembly fast.Sheet Metal Prototypes

Sheet Metal Products

Multipart Assemblies

Industries with Sheet Metal Fabrication

Resources for Sheet Metal Fabrication