CNC Laser Cutting Services

Sheet plastic and metal prototypes and low-volume production parts shipped in as fast as 1 day

Overview: How CNC Laser Cutting works?

The Basics Of CNC Laser Cutting

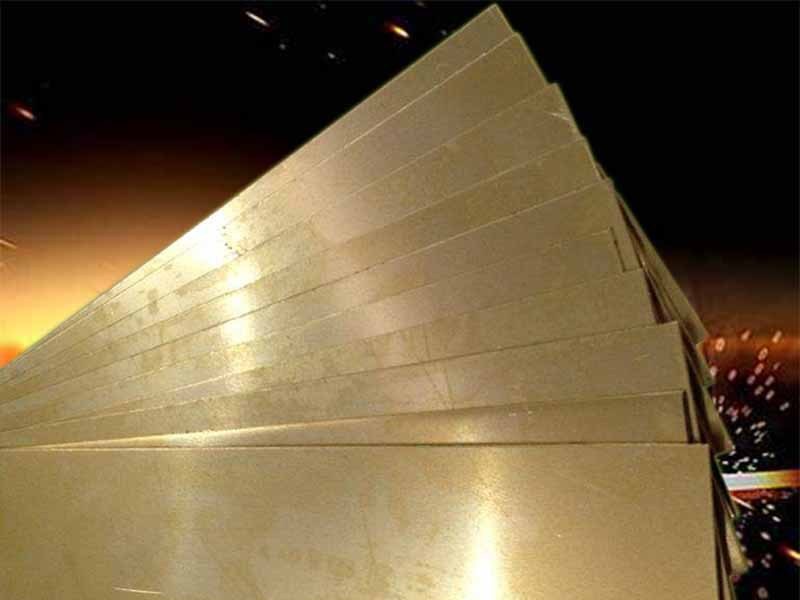

Laser Cutting In Progress

Laser cutting generates the first 2D flat of the sheet metal fabrication. Turnaround time for laser cutting is faster than punching, saving you time on shorter runs, and is more precise and consistent cut than mechanical cutting.

CNC laser cutting produces consistent clean edges to the most exacting tolerances. It is a flexible, versatile manufacturing solution for fabricating parts with complex geometries that require distortion-free finishes.

How Laser Cutters Works

Laser focusing optics are used to direct electrical energy into a high-density light beam, and CNC is used to manage either the workpiece or the laser beam. The material processed by the laser cutter is then melted, burned, vaporized, or blown away by a jet of oxygen or nitrogen.

Benefits of CNC Laser Cutting with FacFox

Over the past decade, we have proven our expertise in CNC laser cutting services, consistently manufacturing products to high quality and precision standards. We deliver value on all of our projects – unmatched quality products supported by superior customer service at competitive prices.

- Custom shapes and complex geometries

- High repeatability in production

- Minimal work hardening and metal distortion on completed parts

- Rapid turnaround, with overnight delivery available for rush orders

- Finishing services offered through our network of trusted partners

- Short runs through full production

- No tooling cost reduction

Features of CNC Laser Cutting

Advantages

Drawbacks

CNC Laser Cutting Processes

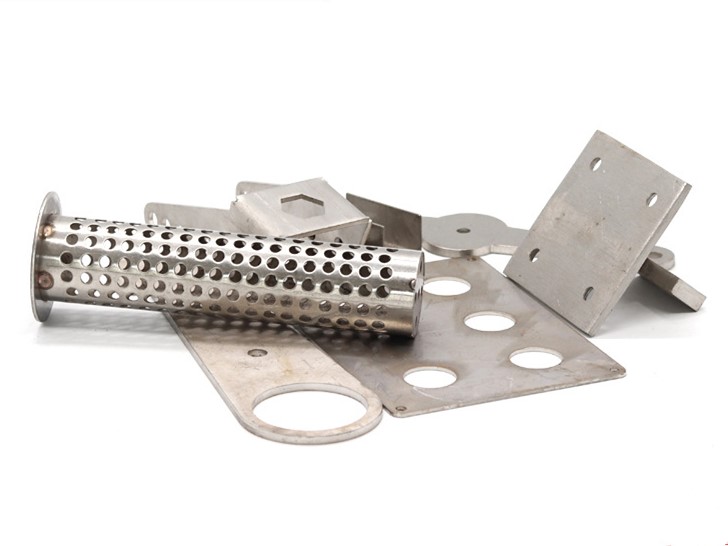

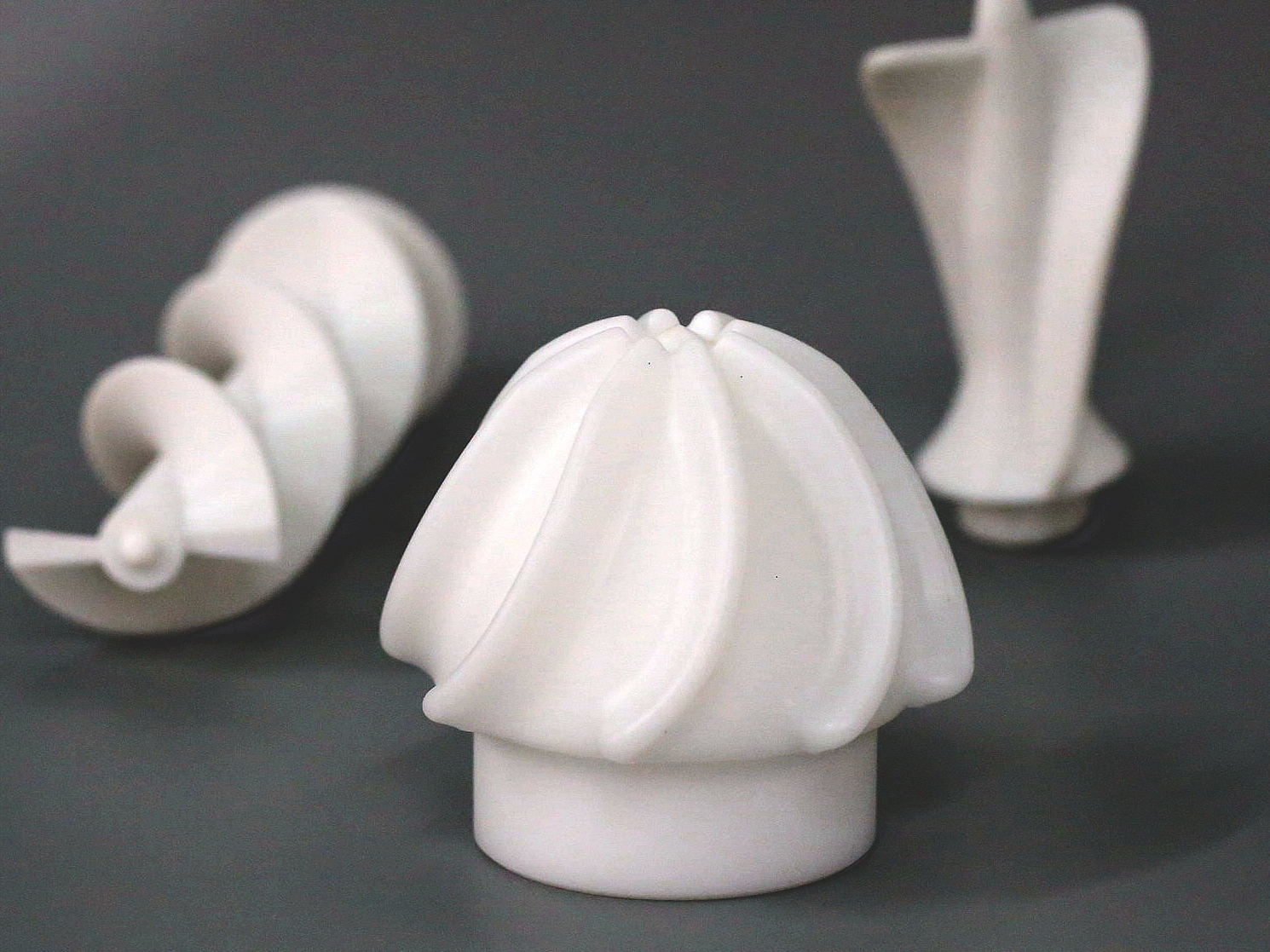

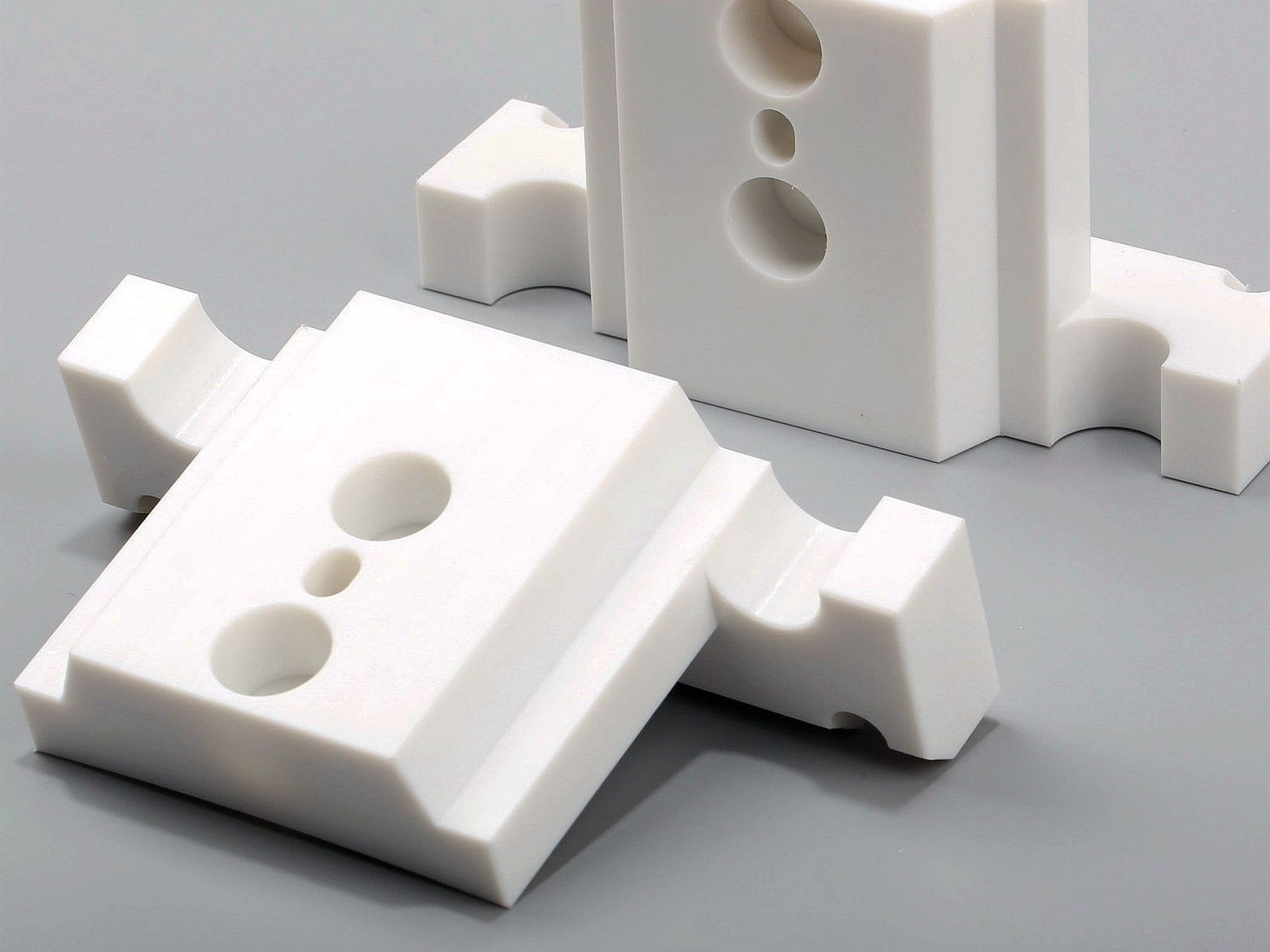

2D CNC laser cutting produces consistent clean edges to the most exacting tolerances. It is a flexible, versatile manufacturing solution for fabricating parts with complex geometries that require distortion-free finishes. 3D laser cutting is used to cut slots, holes, corners, and other features in parts such as tubes, channels, angles, and beams. Using a 5-axis laser cutter, 3-D laser cutting is fast, precise, and repeatable. Multi-axis machinery can produce precision parts with complex geometries and surface features in one process.2D Laser Cutting

3D Laser Cutting

Available Materials

Available Finishes

The finish option with the quickest turnaround.

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants.

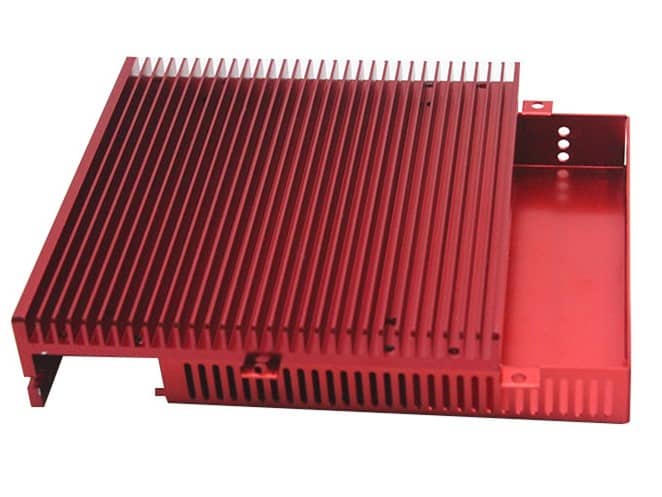

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in coating and is then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware and automobile and bicycle parts.

- Electroplating

- DonŌĆÖt see the finish you need? Submit an RFQ with ‘Suggest’ option, weŌĆÖll look into a finishing process for you.

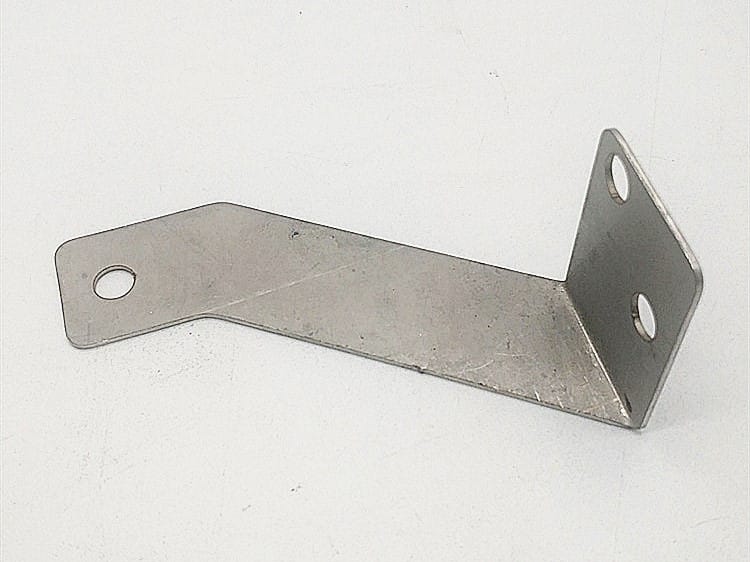

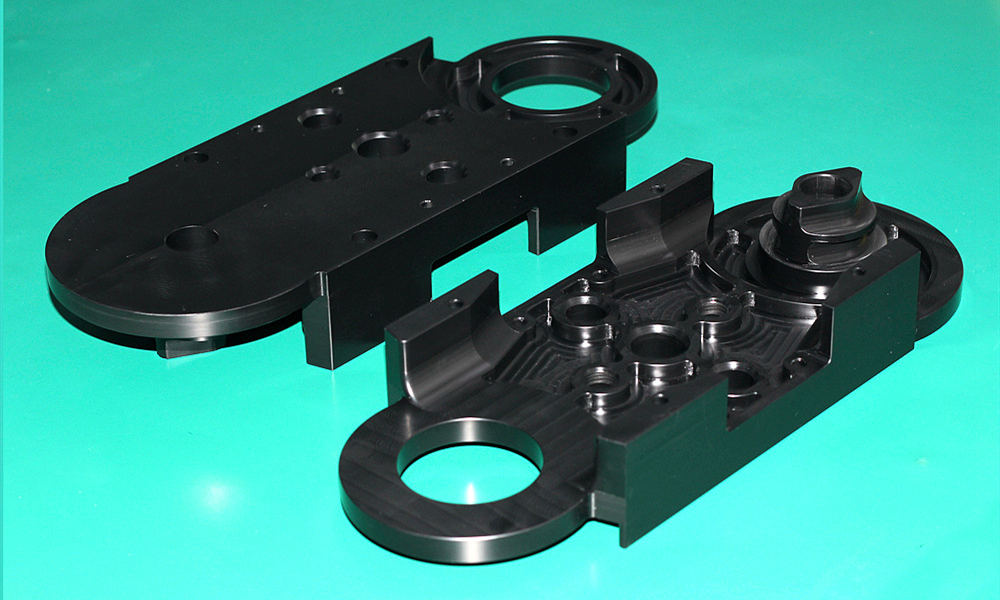

CNC Laser Cutting Applications

Whether you need a bracket, chassis, enclosure, or any other complex sheet plastic/metal design, weŌĆÖll ship 1 to 50+ prototypes in as fast as 4 days. Get the same great service of our prototyping shop higher volumes. Our low-volume production facility can produce up to 50 to 1,000+ sheet pastic/metal parts in as fast as 10 days. We provide a partial or complete prototype assembly in 2 to 3 weeks. We help coordinate the procurement of your custom and catalog parts to build your electro-mechanical assembly fast.Prototypes

End Products

Multipart Assemblies

Industries with CNC Laser Cutting