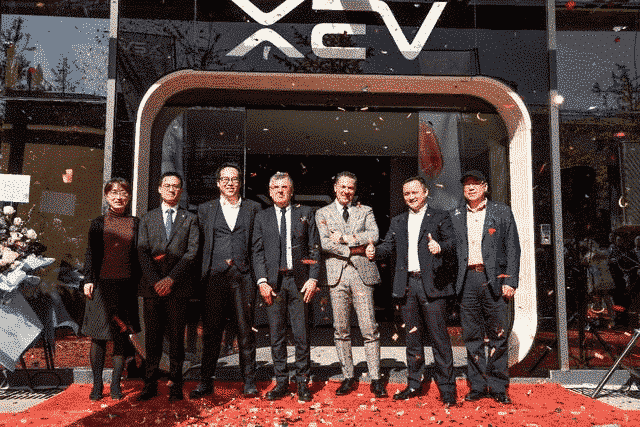

On November 11, 2019, the XEV Shanghai Center officially opened in Baoshan district, Shanghai. As a new XEV innovation center beside the formerly established centers in Italy and Hong Kong, XEV Shanghai will have an integrated R&D capability in industrial additive manufacturing applications, providing intelligent and complete 3D printing solutions for the automotive industry.

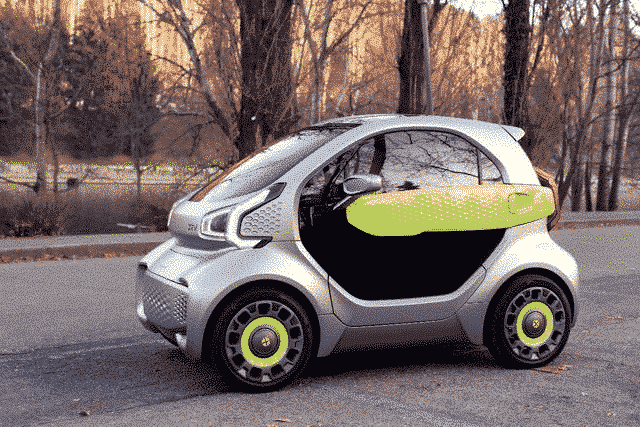

XEV (X-Electrical Vehicle) is an auto manufacturing company with the core technology of 3D printing auto manufacturing and Internet genes. It mainly engaged in R&D, production and sales of high-end and intelligent pure electric vehicles as well as 3d printing equipment. Its products cover small urban travel autos, including SUV, MPV and other pure electric vehicles. Centering on 3D printing technology, XEV is committed to building a complete automobile eco-system and creating the ultimate urban user experience.

Mr. Rudy, the founder and CEO of XEV, delivered the keynote speech at the opening ceremony of Shanghai center. He says, “XEV Shanghai will be one of our top three R&D centers around the world, integrating the best international resources for the future development of 3D printed vehicles. 3D Printing technology does not need molding and large-scale stamping, casting equipment. On the contrary, it can achieve customization and flexible production, save development time and cost, so as to meet the needs of different customers and users.”

In 2019, XEV has entered into an exclusive strategic cooperation agreement with Polymaker, ATMAT and Kuying technology, the leading global suppliers of 3D printing materials, to jointly develop car-scale 3D printing materials, large-size 3D printers and a full set of solutions for high-volume production.

Qu Hang, deputy general manager of Polymaker, said: “mass production is undoubtedly the future of 3D printing for automobiles, and XEV is the first to bring that future into reality. As XEV’s exclusive strategic partner in the field of vehicle 3D printing materials, Polymaker hopes to partner with XEV to provide better performance materials and contribute to the innovation of 3D printed vehicles.”

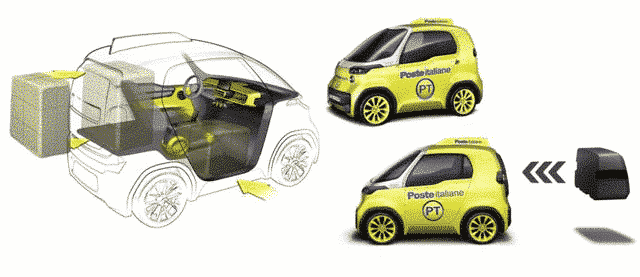

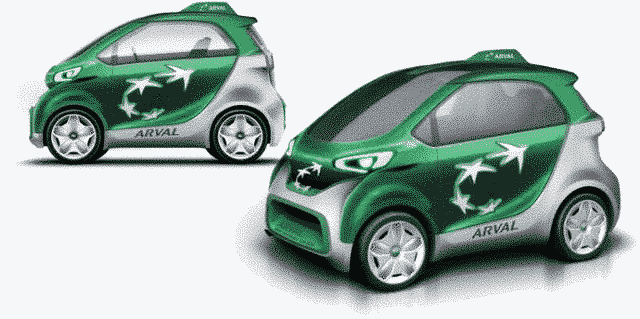

Due to its fast customization and low-cost flexible manufacturing technology, XEV has received pre-orders for 7,000 units from Italy post and ARVAL, Europe’s largest transport company. Recently, XEV is closely preparing for the mass production of the first model “YOYO” and has received strong support from the investor team including China innovation ocean, a new leader in China venture capital.

Entering the mass production stage, XEV will be produced in partnership with China’s top manufacturers, with an annual capacity of 10,000 units and expected to be launched in the fourth quarter of 2020. With the advantages of leading industrial 3D printing additive technology and innovative customized business model, XEV is looking forward to reshaping the new energy vehicle industry and creating better value for users and society.

Leave A Comment