World’s largest 3D-printed building completes in Dubai

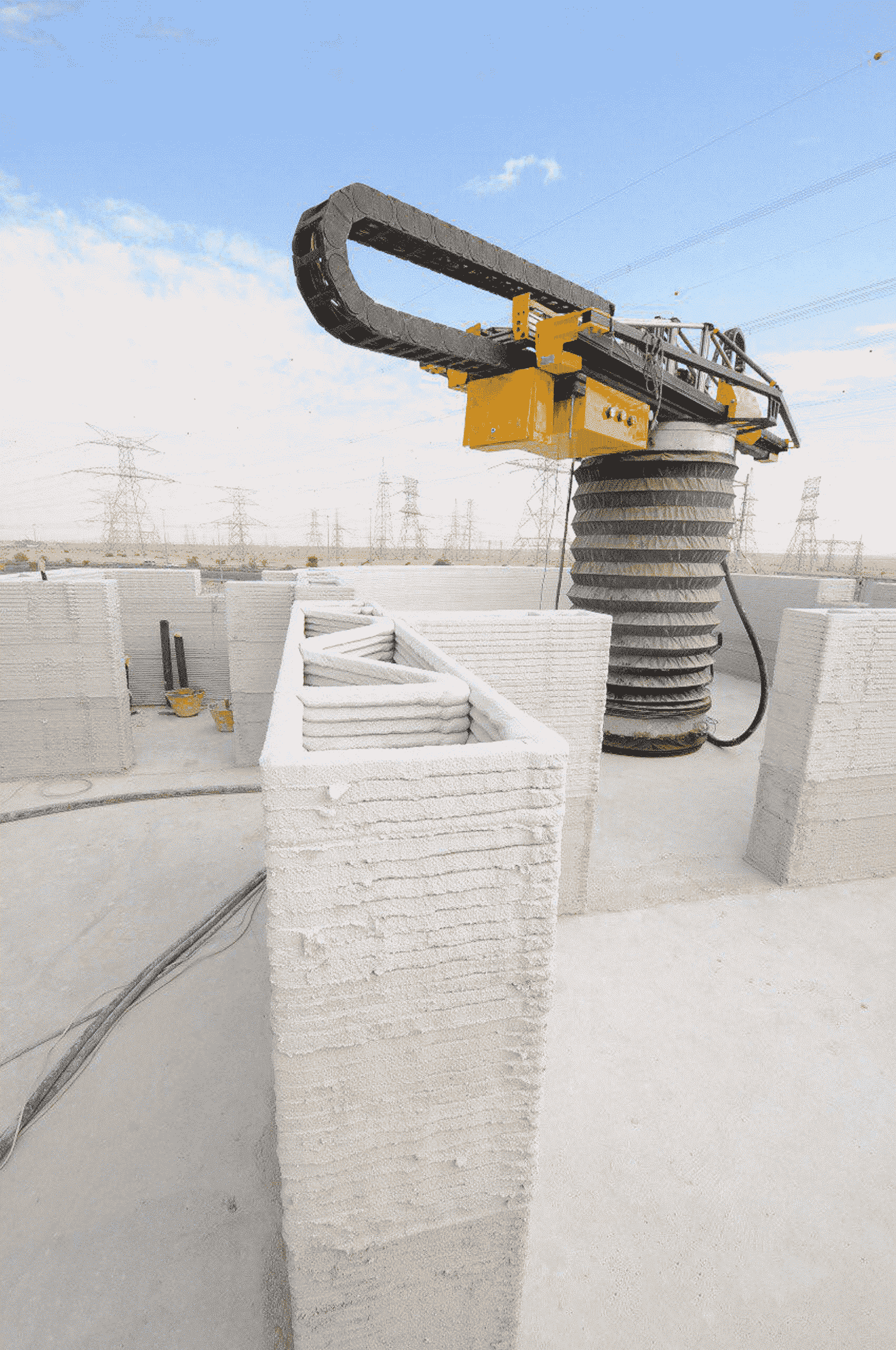

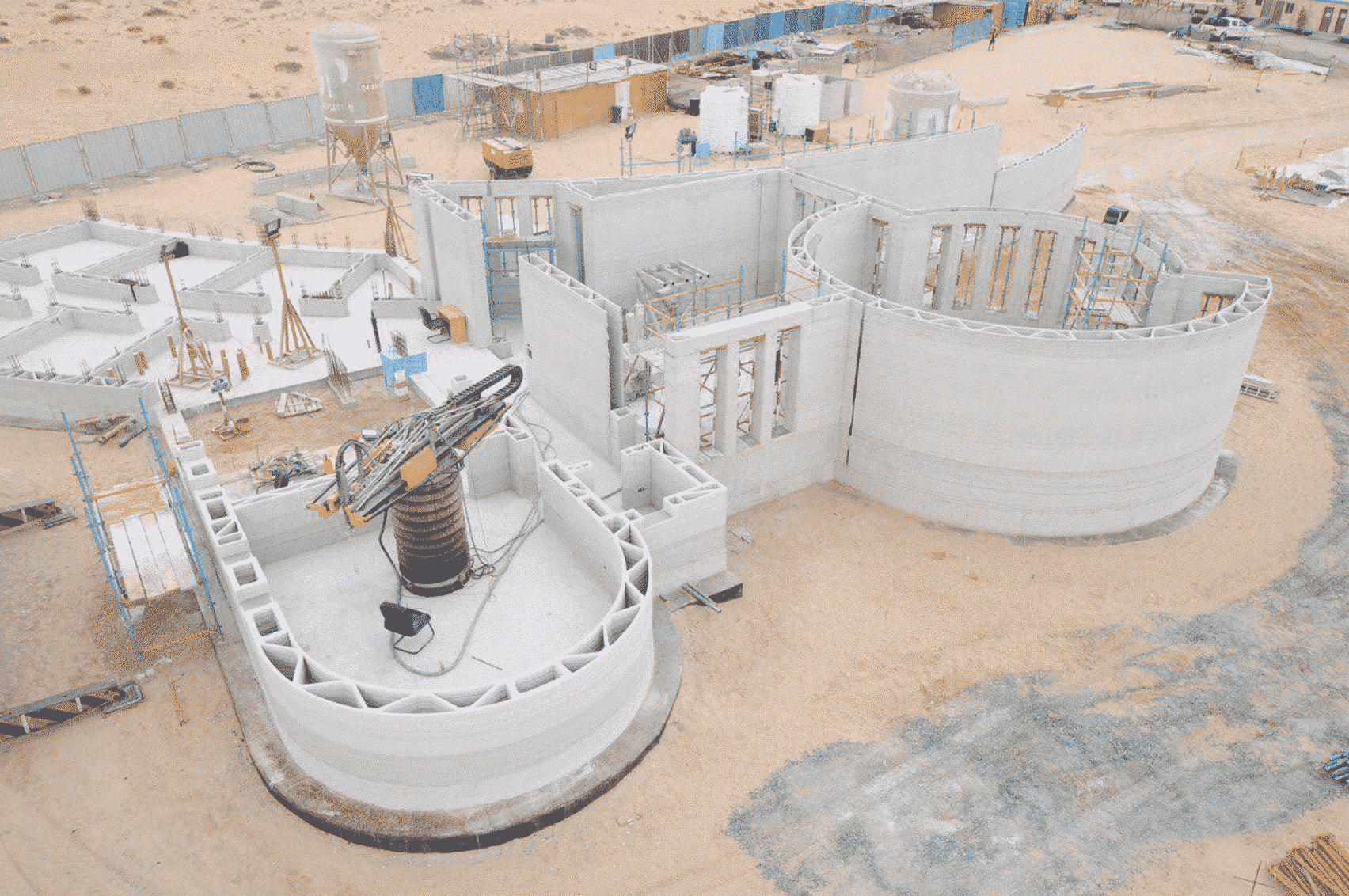

Last week, the world’s largest 3D-printed building completes in Dubai, which is a two-story office for the Dubai Municipality measuring 9.5 meters high with a floor area of 640 square meters. Apic Cor claims that their printing is the largest 3D-printed building ever built.

Apis Cor is a robotic construction company that develops specialized equipment for 3D printing in the architecture industry. Their technology is capable of printing wall structures entirely on-site without extra assembly required.

They employed three workers to operate the 3D printer. The whole construction period of this building is only three weeks.

This project is a huge step forward in the concrete 3D printing industry. Basing on the conventional foundations, Apis Cor uses a crane to reposition the only 3D engaged printer. The main material they fill into the printer is gypsum-based filament sourced from a local producer.

Certainly, concrete and rebar are also needed to reinforce the printed column, which is not strong enough to support the whole building solely. Pre-cast slabs were used for the floors, and conventional windows and roofs were added by a contractor once the walls were printed.

The whole process took place in an uncovered area, meaning such harsh environment requirements for 3D printing material like temperature and humidity were uncontrolled.

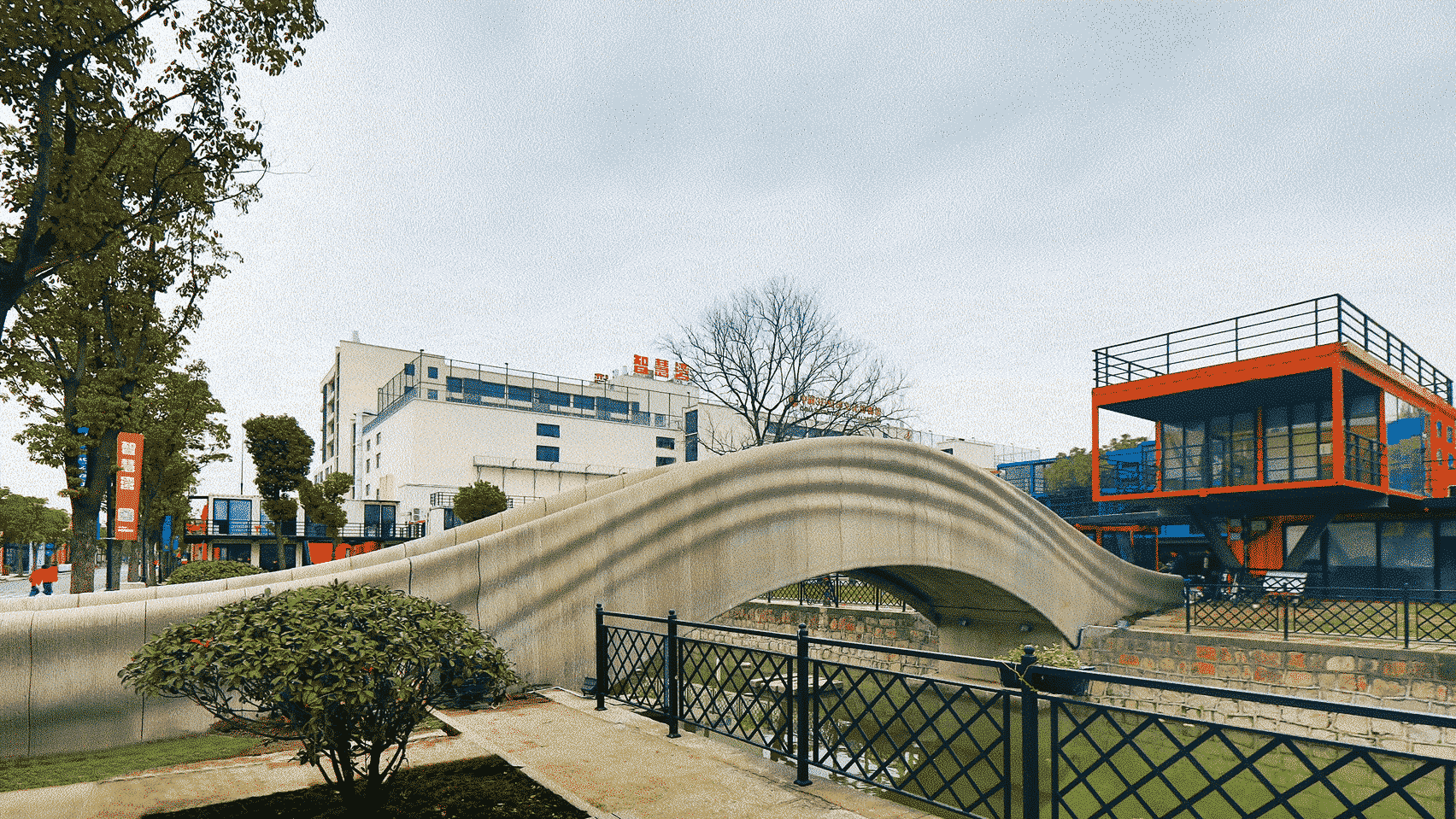

World’s longest 3D-printed concrete bridge opens in Shanghai

Earlier this year in February, Professor Xu Weiguo led his students from the School of Architecture at Tsinghua University and printed the world’s longest concrete bridge in Shanghai’s Baoshan District.

The concrete bridge is a 26.3-meter-long and 3.6-meter-wide pedestrian bridge that spans a canal. The bridge’s arched form is informed by the 1,400-year-old Anji Bridge in Zhaoxian, which is China’s oldest standing bridge.

The single-arched bridge was constructed from 176 concrete units that were printed using two robotic-arm 3D-printing systems. All of the components were printed within 450 hours.

All the components of the bridge are printed using a composite of polyethylene fiber concrete and admixtures. The designers said it’s eco-friendly, cleaner and cheaper compared with the traditional building method, cause the main body doesn’t need any templates or reinforcing bars before printing, which constitute 1/3 of the original cost.

The institution believes that the bridge marks a step towards the emerging technology being utilized more regularly on real-world engineering projects.

The bridge is embedded with a monitoring system that will record how the concrete deforms over time. This information will be used to further help develop the use of 3D printing for engineering.

World’s largest 3D-printed home in America

The S-Squared team printed a home on West Main Street in Patchogue, which is measured about 500 square feet with 8-foot walls and a 12-foot roof. Measurements and photos were submitted to Guinness World Records and Wikipedia.

It took only about 12 hours to print, plus a little extra time to install the roof. The retail cost would be about $10,000-$15,000 to build, outfitted with plumbing and electric. The homes are all printed by S-Squared 3D printers and 4D commercial’s machine/system called ARCS — automatic robotic construction system — which measures 18 feet tall by 32 feet wide. All homes are fire, hurricane, tornado and mold resistant.

The company says the cutting-edge technology has the potential to be the next big thing to help improve community infrastructure, with practically zero carbon footprint. By reducing the manpower and resources, the home printer can build a house in a fraction of the time, which relieves the impact on the environment and cutting costs by using eco-friendly materials and methods.

Leave A Comment