The museum plays a role in connecting now and the past, and provides a good way to enrich cultural life. However, due to historical reasons and many factors, the cultural relics in the museum are occasionally damaged. Therefore, it is particularly important to repair the damaged cultural relics. Restoring their original shapes and textures is extremely important for cultural relics protection and research. significance.

According to statistics, there are currently more than 2 million cultural relics that need to be restored in China, such as bronze, porcelain, calligraphy, and so on. This is a huge project. The hugeness is not only reflected in numbers, but the difficulty in the restoration of cultural relics. That’s why so many cultural relics have not been restored. This not only requires a lot of time and financial resources, but also bears the risk of damage caused by improper repair.

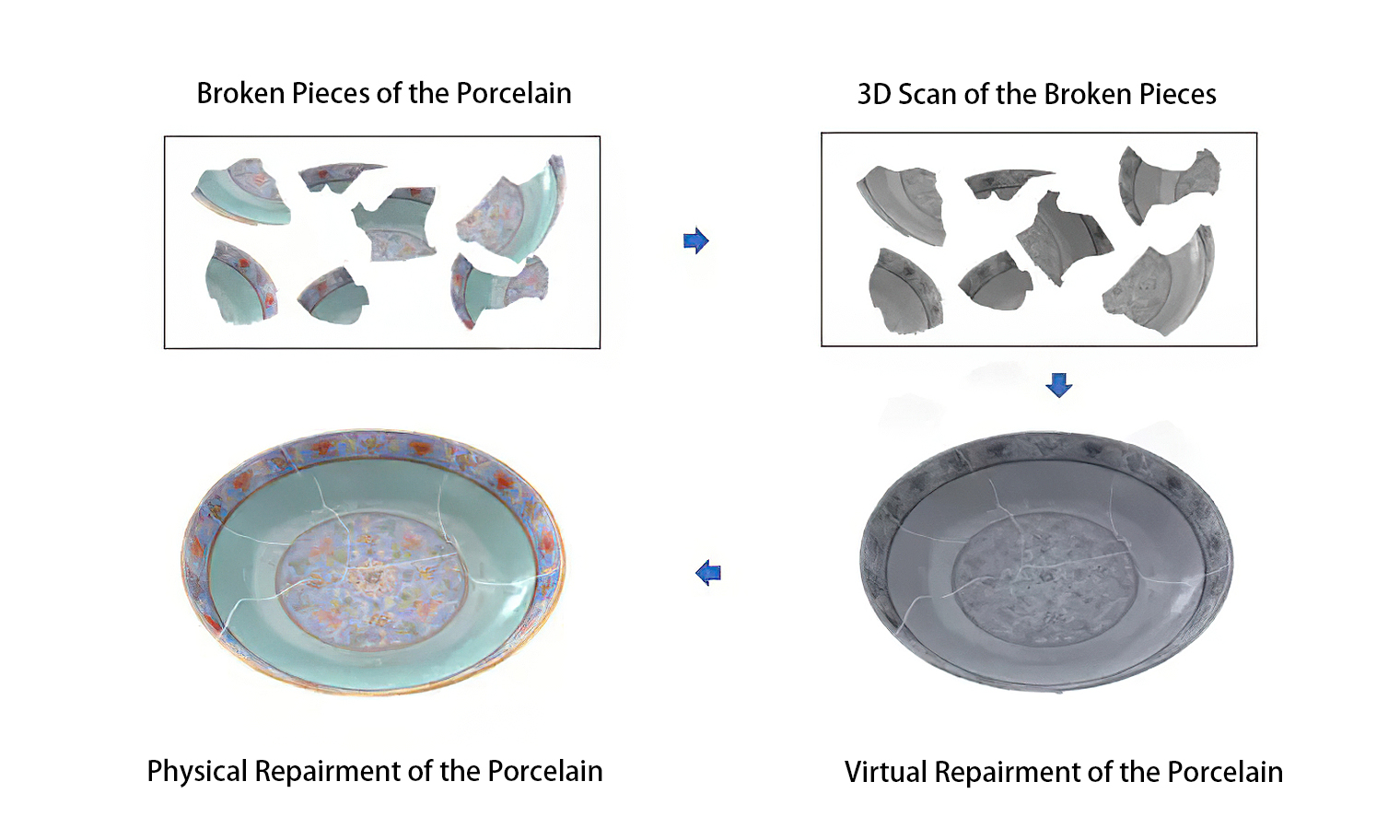

3D scanning technology can fully solve this problem. Compared with traditional methods, the use of 3D scanning technology to collect data has advantages of fast speed and accurate collection. At the same time, due to its non-contact working method, the collection process will not cause secondary damage, and high-resolution imaging will also make post-processing and stitching more accurate and perfect.

The contactless working method is fast and safe.

The 3D scanner does not need to be in contact with the porcelain in the process of collecting data, which avoids possible damage to it due to physical contact.

And the whole data collection process of the porcelain can be completed in 5 minutes.

Compared to the traditional method, 3D scanning has high precision.

Using a 3D scanner, high-precision 3D models can be obtained instantly. Compared with traditional manual measurement, the model data obtained by 3D scanning only has an error of 0.03mm, which brings great accuracy to data inspection and restoration.

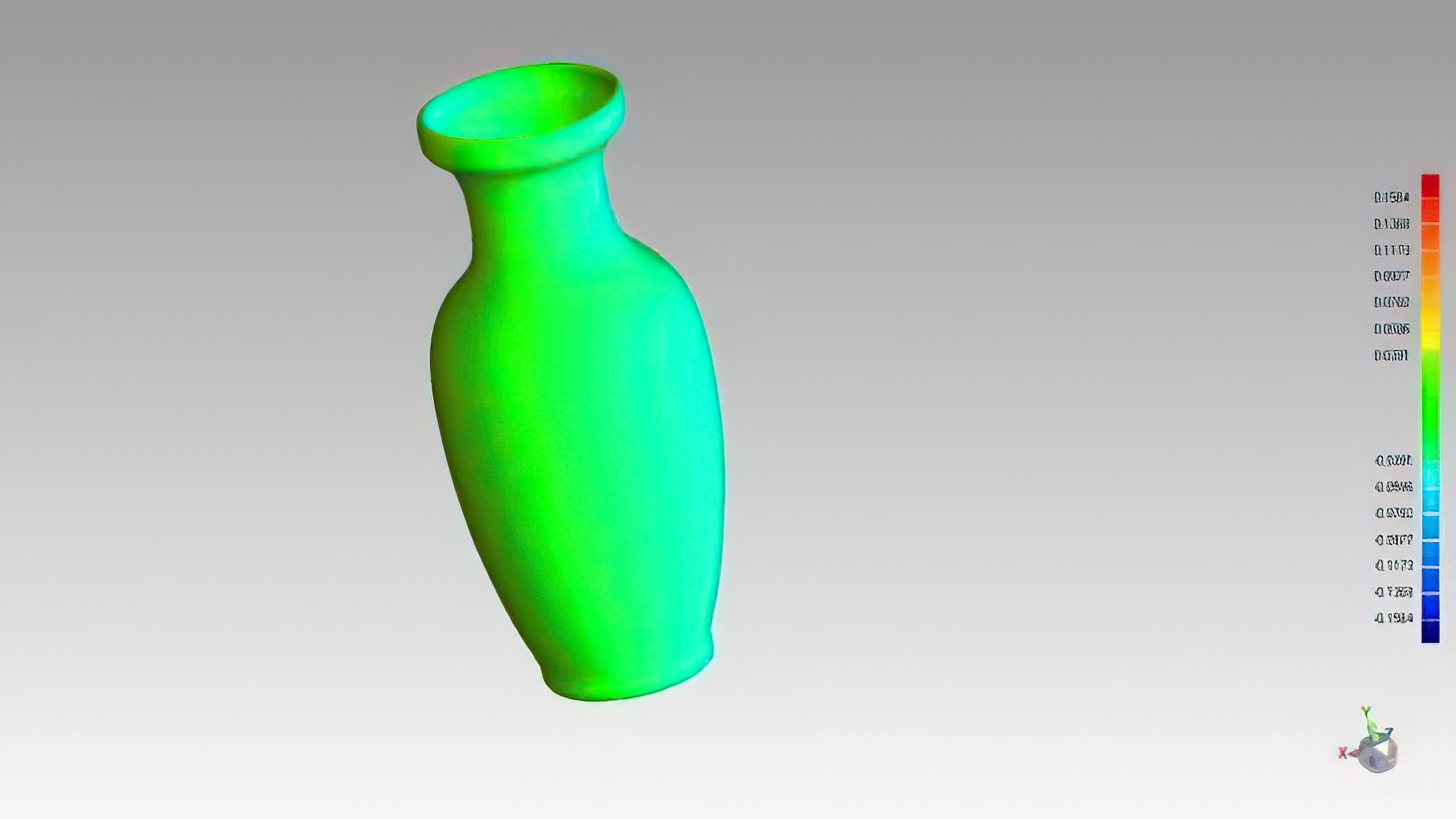

It’s more direct and simpler to distinguish the defects.

The 3D color map can intuitively show the damage level and locations of the porcelain.

3D scan has a high degree of reduction of color and shape.

The 3D scanner can accurately obtain high-precision surface point cloud data in a very short time, less than 5 seconds. The tolerance of the point cloud reaches 0.02mm.

And the scans contain high-resolution texture information, each image has a resolution of 36 million pixels, which means the colors can be perfectly reproduced.

Conclusion

Conclusion

In summary, 3D scanning technology has played an important role in the digital restoration of cultural relics. Virtual stitching can be realized through scanning, and a textured, high-precision 3D model can be generated, which provides accurate data support for the later 3D printing process.

With the improvement of 3D scanning and 3D printing technologies, the restoration of cultural relics will be more efficient and easy.

Conclusion

Conclusion

Leave A Comment