Using an Artec Eva 3D scanner and the large-format Stratasys F900 3D printer, the team at Camosun Innovates is creating replica whale bones to fill in missing pieces of massive displays in museums across the world.

Camosun Innovates is on the campus of Camosun College in Victoria, British Columbia, Canada. It is home to the Camosun Technology Access Centre, an applied research and innovation center that gives local companies access to specialized technology, equipment, and expertise. They help clients develop, test, and refine products, and generally find creative solutions to clients’ most puzzling challenges.

The center is easily one of the most well-equipped for additive manufacturing technology and applications in western Canada, and one of the few to have the Stratasys F900 3D printer.

Camosun Innovates makes replicas of missing whale bones for their client Cetacea Contracting of Salt Spring Island, BC. Cetacea creates marine mammal skeleton exhibits for museums, which, thanks to Camosun Innovates, are now home to 3D printed replica bones. The stand-in parts are used to complete a display when a real bone of that type is not available.

The 3D printed whale bones are precise, durable, and cost-effective, and can be made quickly. Compared to traditional methods of model making, such as hand carving or using silicon molds, using 3D scanning, digital data manipulation, and 3D printing saves many thousands of dollars and shaves nine months off the production time. Since partnering with Camosun Innovates, Cetacea, a small family-run business, has been able to increase its staff and capacity, helping them expand on its mission to create skeletons that inspire understanding and protection of the natural world.

Matthew Zeleny, Applied Research Technologist at the Camosun Technology Access Centre, leads the projects that involve digitization and additive manufacturing.

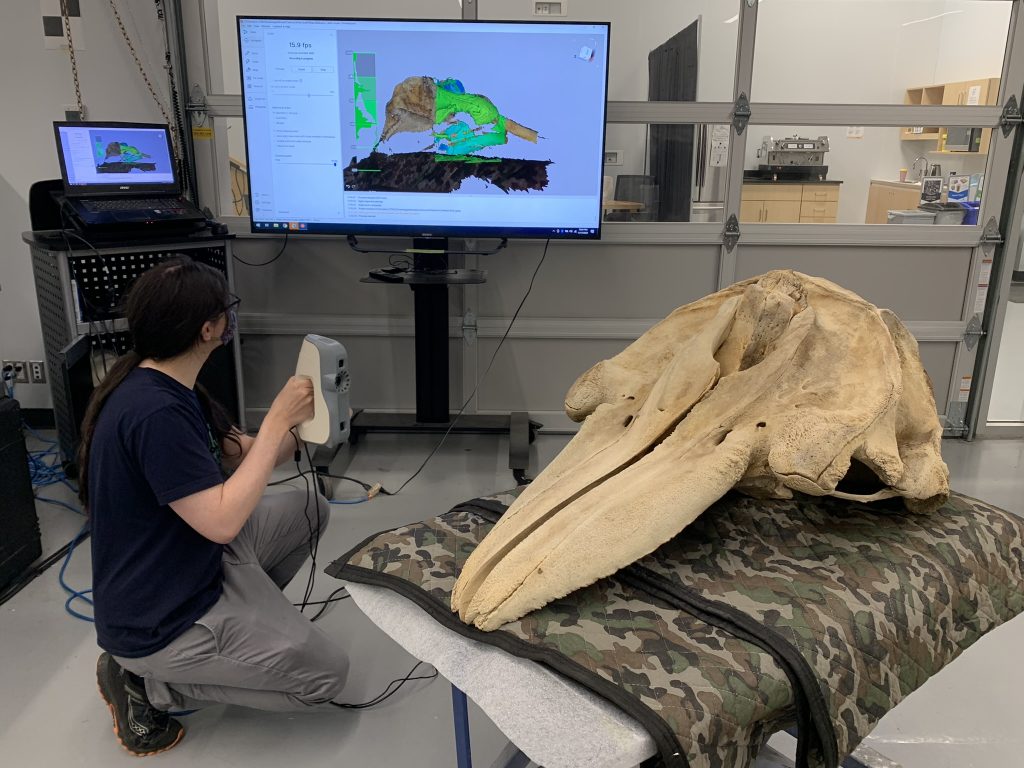

He said that sometimes his team receives the scanned data for the bones and sometimes they do the scanning themselves, using the Artec Eva 3D scanner. The Eva is a handheld, versatile scanner that captures precise measurements in high resolution. Using a combination of Geomagic Wrap, Geomagic Design X, and SOLIDWORKS, Matt’s team works closely with Cetacea, leveraging scanned data for articulation planning and armature design, and to create either full replicas or prosthetic caps for partial bones.

Bones they have scanned in-house include those from a Cuvier’s beaked whale and a baby humpback.

“Manipulating scanned data is like replacing a traditional modelmaker’s hands with our digital hands,” Matt said.

Manufacturing on Demand

Large-scale projects, like printing whale bones, require a large-format, industrial 3D printer (one jawbone replica is 14 feet long). The Stratasys F900 tray measures 36 x 24 x 36 inches and has 18 cubic feet of build volume. It offers 16 different high-performance materials to serve a large array of manufacturing applications.

For the replica whale bones, the team uses white ABS-M30. They print the skeleton pieces in 1.5 mm shelled sections, fill the core with expandable foam, and connect the pieces using ABS plumbing glue.

Matt said the F900’s large build envelope, along with the variety, strength, and thermal stability of the print material, meets the demands of local industry, who want reliable, repeatable results.

“Having a premium commercial unit here differentiates us. We can do things that can’t be done elsewhere in the region.”

He added that it’s also about sharing knowledge and expertise with clients.

“Technology is always evolving, and we are the go-to. People come here not just to use the technology – they want to learn how to use it well. Our mix of technology allows us to find creative ways to blend the technology to get the best possible results.”

With access to premium technology in the center, Camosun College faculty and students from a variety of disciplines can enhance their work and studies. Beyond 3D printing replica whale bones for museums, faculty can take on applied research projects and students get exposure to the advanced equipment and processes they will encounter in the workforce.

The center’s diversity of advanced manufacturing projects is impressive, from laser cutting trays to aid in the safe distribution of Pfizer vaccines to remote communities, to designing and printing custom seating and assistive devices for parasport athletes.

For almost 10 years, Camosun has relied on Javelin for the latest in software, hardware, and technical advice.

“Javelin (now TriMech) is our one-stop-shop. They support us with SOLIDWORKS tools, 3D scanning technology, and 3D printers, and have helped us with grant applications to secure essential infrastructural funding. They provide technology, services, and advice, just like we do for our industry clients.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment