The UK’s Engineering and Physical Sciences Research Council (EPSRC) has awarded a team at the University of Nottingham £6 million to develop a toolkit that helps get 3D printing into the country’s hospitals and surgeries.

Using this grant, researchers at the university’s Centre for Additive Manufacturing (CfAM) plan to come up with an instructional toolkit that facilitates the 3D printing of custom medical devices across the NHS. It’s thought the scientists’ platform could allow for the development of treatments such as prosthetic limbs, ‘smart pills’ and even intestinal patches that rebuild tissues damaged through chronic disease.

“This is very exciting work which, through building cellular models, will improve our understanding of how the gut functions,” said Professor Mohammad Ilyas, a consultant at NHS Nottingham. “More importantly, if successful, it will lead to a paradigm shift in clinical management and launch the use of autologous tissue-engineered therapeutics for the treatment of bowel disease.”

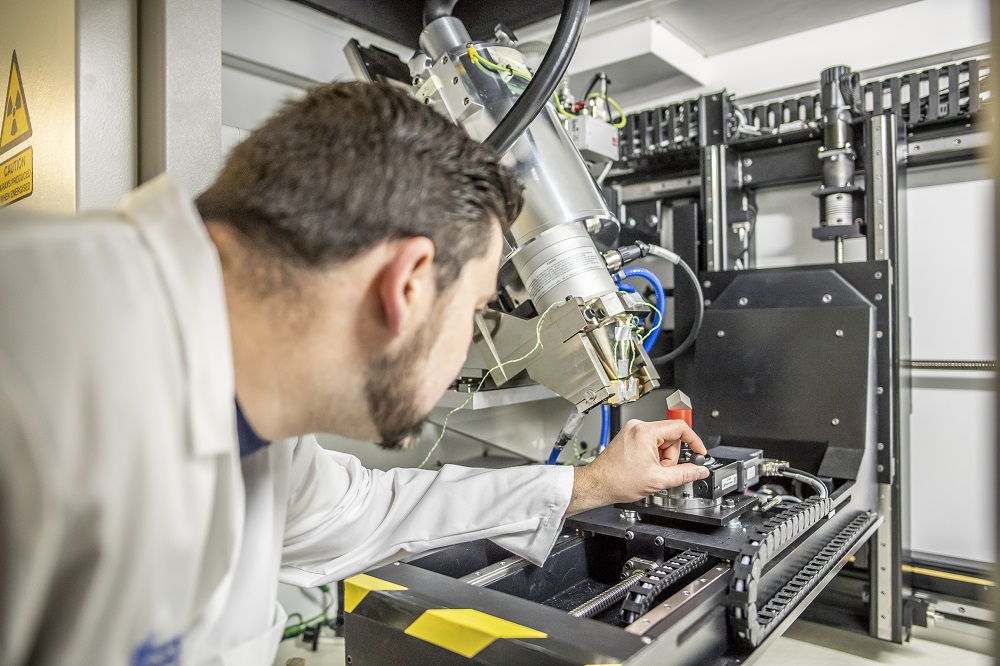

Nottingham’s Centre for Additive Manufacturing

Located on its Jubilee Campus, the University of Nottingham’s CfAM carries out fundamental and applied research in the field of 3D printing. As the technology advances, the team there believes it’ll move beyond the use of single feedstocks into a form of multiple-material printing, in which the functional and structural are deployed in unison to unlock durable, life-changing medical devices.

To help facilitate this transition, Nottingham’s CfAM group is working to investigate the processes, materials, and computational methods, that underpin the 3D printing of multifunctional parts. The group also works with commercial partners to translate its technology into real-world use cases, and it has even set up a consultancy firm, Added Scientific, to properly engage with industry.

In the past, the university’s work has seen it investigate the use of 3D printing for secret information storage and collaborate with University College London to develop a 3D printed brain helmet. Nottingham researchers have also previously contributed to a Massachusetts Institute of Technology (MIT) study into 3D printing’s environmental impact.

Driving AM adoption in the NHS

While medical 3D printing continues to make advances in lab-based scenarios, the technology is rarely used in the wider healthcare sector. No doubt, demand for such patient-specific devices remains strong, but bringing them to market can be a lengthy task, as they face roadblocks around materials and regulatory approval.

To get around these issues, the EPSRC, the UK’s main funding body for engineering and physical sciences research, has tasked Nottingham’s CfAM team with developing a toolkit that improves their pathway from research through to adoption, by giving clinicians faster access to cutting-edge technologies.

Manufacturing on Demand

According to the scientists, medical staff need devices with ‘advanced functionality’ that can be 3D printed quickly, predictably, and reliably, and deliver ‘dial up’ performance. In practice, it’s hoped the team’s platform will facilitate this, by providing the NHS and medtech firms with a toolkit that helps accelerate the process of identifying the right materials and processes for a given job.

“Throughout the pandemic, we saw the COVID-19 vaccines develop at record speed and be implemented safely for the public good,” explained Ricky Wildman, a Professor in Chemical Engineering at the University of Nottingham. “We now have the chance to build on this success to continue to transform the way we get innovation that makes people’s lives better to market and to clinic.”

Once ready, the team’s platform is set to be rolled out across hospitals, pharmacies, and the wider NHS. In doing so, the Nottingham researchers aim to help realize 3D printing’s potential as a way of producing highly-functional biopharmaceutical products, regenerative medicines, biocatalysis solutions, and more, that would otherwise be impossible to create via traditional manufacturing.

“Multi-material, multi-functional additive manufacturing has the potential to revolutionize the way we realize medtech innovation,” added Wildman. “This funding will transform the market adoption of medical devices and therapies that are truly life-saving for patients.”

Although 3D printing is a long way from being deployed at scale in the NHS, it continues to find one-off applications in surgical planning and patient-specific implant production. Late last year, a cancer patient was treated with a 3D bioprinted nose grown on her forearm, by clinicians at the Claudius Regaud Institute and Toulouse University Hospital.

In a more conventional application of the technology, doctors in Dubai also announced that they’d managed to treat a patient’s deformities with 3D printed titanium face implants. The one-of-its-kind case saw the team completely reconstruct the male patient’s facial bones, which had been severely damaged from several benign tumors.

You might also like:

Injured Ukrainian soldiers treated with cutting-edge 3D printed bionic arms: Controlled by sensors activated in the forearm, the firm’s Hero Arm features a moveable thumb and fingers that enable users to grasp objects more effectively than traditional prosthetics allow. Having recently been fitted with Open Bionics’ device, Vitalii Ivashchuk, one of those being treated, says he already has a “very cool feeling” with it, and has expressed his gratitude for its daily functionality.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment