UltiMaker has added PET Carbon Fiber (CF), an easy-to-use and versatile composite material, to its portfolio of high-performance materials for S series 3D printers. UltiMaker PET CF offers superior strength, high heat resistance, and high chemical resistance for strong high-performance thermoplastic applications for a wide range of industries.

With its exceptional mechanical properties, UltiMaker PET CF empowers engineers to produce stronger and more accurate parts for a multitude of applications, such as manufacturing tools, jigs and fixtures, and end-use parts. Engineers can also leverage the benefits of the material for their engineering prototypes – enabling easy and extensive testing of technical concepts and functions. Moreover, the material offers a reliable solution for replacing broken or hard-to-source production parts. By utilizing its strong mechanical and thermal properties, manufacturers can swiftly print replacement components. The material’s excellent strength and stiffness make it ideal for high-performance applications – delivering enhanced part performance under demanding conditions.

One of the standout features of PET CF is its ability to achieve even higher strength, stiffness, and temperature resistance through annealing. By annealing printed parts, engineers can achieve a temperature resistance of up to 181°C, increase strength by up to 30%, and stiffness by up to 10% – resulting in parts that excel in challenging environments.

Manufacturing on Demand

“We are thrilled to introduce the UltiMaker PET CF, UltiMaker’s first composite material that has been optimized for UltiMaker S series printers,” said Nadav Goshen, CEO of UltiMaker. “PET CF’s ability to achieve higher strength and temperature resistance through annealing sets it apart from other materials, while its versatility allows engineers to use it for a number of applications. The material represents a significant advancement in our portfolio and reinforces our commitment to delivering cutting-edge solutions.”

Exhibiting low moisture sensitivity compared to other carbon fiber materials, PET CF requires limited drying. When stored in the UltiMaker Material Station, it remains well-conditioned – enabling a reliable printing experience and consistently high-quality prints. The material is compatible with dedicated support materials, such as UltiMaker PVA and Breakaway – offering users full design freedom and enabling the creation of complex composite parts without limitations.

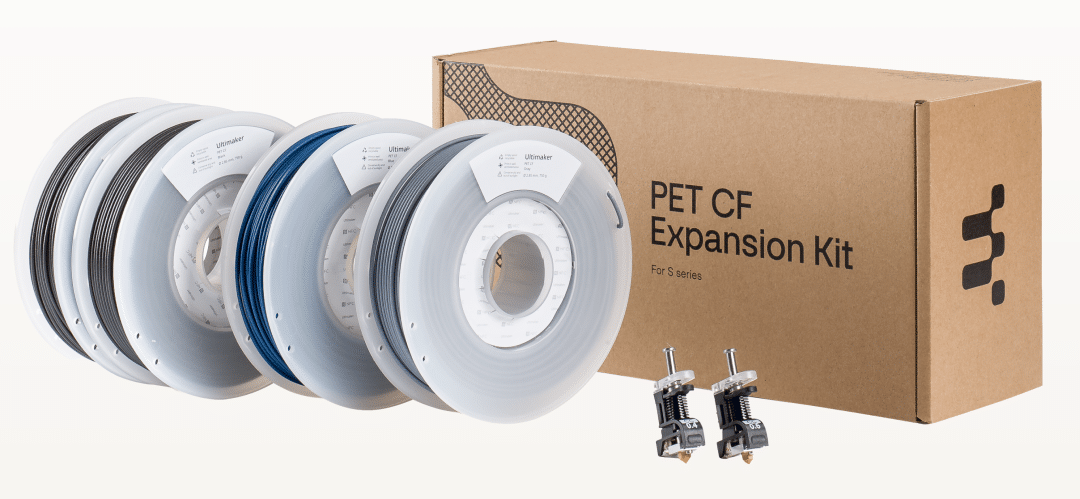

UltiMaker also offers PET CF in multiple colors, including black, gray, and blue. This feature allows users to color-code their carbon fiber prints – catering to specific use cases or aesthetic requirements. The material is fully integrated into the UltiMaker platform through NFC-equipped spools – offering a seamless experience that makes use of NFC material recognition, a dedicated Print Core CC, support material compatibility, and intent profiles.

For users who want a complete composite printing solution, PET CF will also be available as part of the UltiMaker PET CF Expansion Kit. The Expansion Kit includes two spools of PET CF in black and one spool each in both blue and gray. It also includes one 0.4mm Print Core CC and one 0.6mm Print Core CC.

You might also like:

3D Systems and Oerlikon partner to scale metal AM: As part of this agreement, Oerlikon AM is acquiring its fourth 3D Systems DMP Factory 500 system, the first Oerlikon AM is adding in the U.S., to be part of the manufacturing workflow in its North Carolina facility. This will help expand Oerlikon’s end-to-end supply chain solution for high-precision, complex aluminum components for the U.S. market.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment