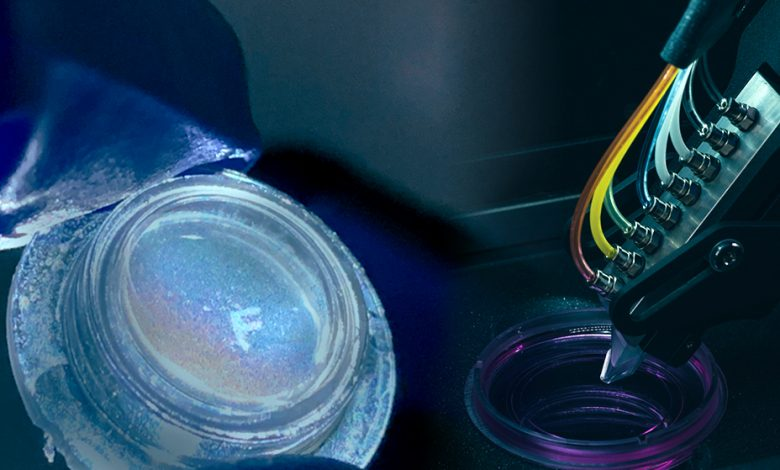

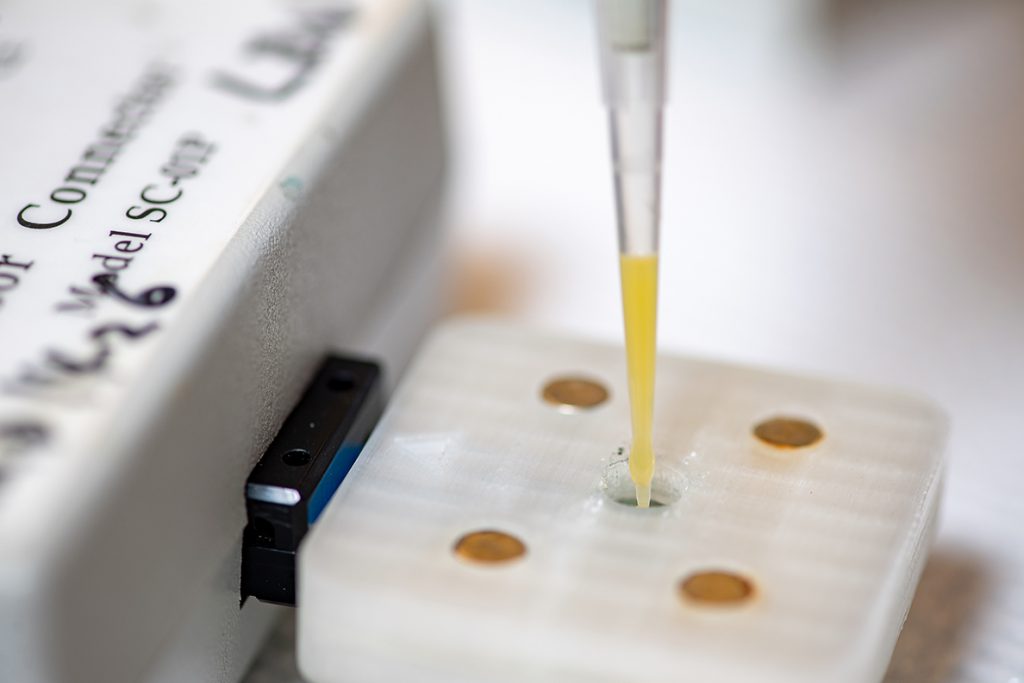

Introducing the 3D Printable Blood Plasma Bio-ink that Accelerates the Wound-healing Process

Scientists at the Irish RCSI University of Medicine and Health Sciences have developed a novel bio-ink that can be 3D printed into tissues capable of fast-forwarding the human wound-healing process.