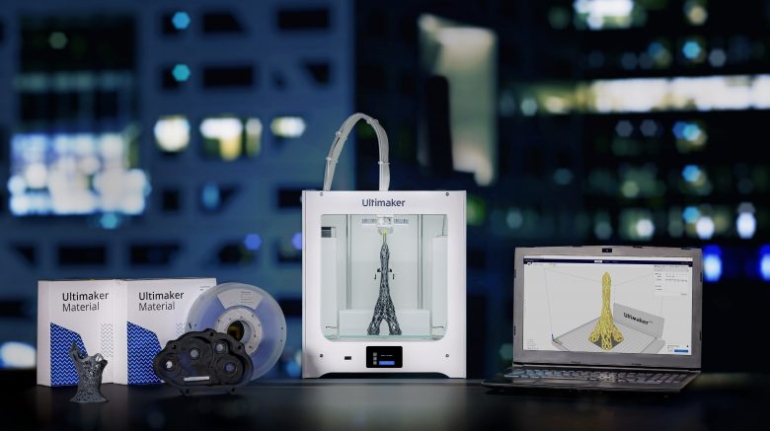

MakerBot Launches METHOD X to Bring Real ABS 3D Printing to Manufacturing

MakerBot is launching METHOD X, a new manufacturing workstation engineered to challenge traditional manufacturing with real ABS (acrylonitrile butadiene styrene) material for durable parts, a 100°C chamber, and Stratasys SR-30 soluble supports. METHOD X can withstand up to 15°C higher temperatures, is up to 26% more rigid, and up to 12% stronger than modified ABS formulations used on desktop 3D printer competitors. MakerBot assures that Precision ABS parts printed on METHOD X have no warping or cracking that typically occurs when printing modified ABS on desktop platforms without heated chambers.