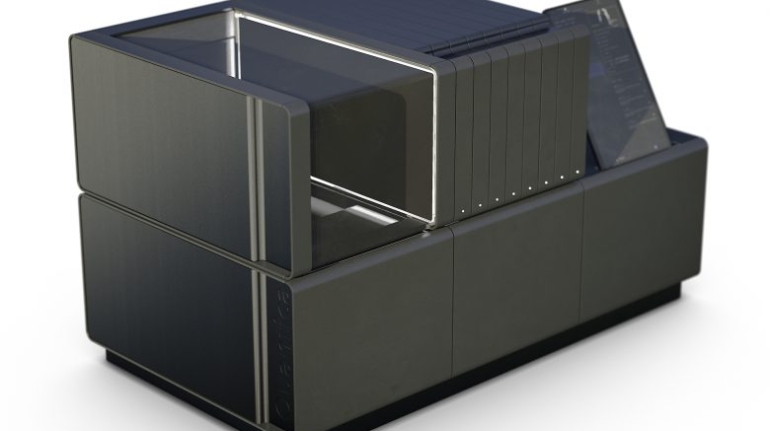

New Massivit 10000-G 3D printer to debut at Formnext 3D Printer Hardware

Massivit 3D Printing Technologies (Tel Aviv Stock Exchange: MSVT), a leading provider of unique gel deposition (GDP) large-scale 3D printing systems, will unveil the new Massivit 10000-G and its flagship Massivit 10000 to the global additive manufacturing market at the upcoming Formnext exhibition and conference in Frankfurt, Germany that takes place on November 15th-18th.