Raise3D, the global provider of additive manufacturing solutions for SMEs and LSEs, is introducing a breakthrough in FFF professional 3D Printing, with the launch of a Hyper Speed Upgrade Kit (HUK3) for the Pro3 Series 3D printers, their flagship professional product.

The gradual adoption of FFF 3D printing has shown that, regardless of its speed, it can be the most competitive manufacturing method to produce prototypes, customize products, meet individual needs, and to carry out small batch production.

Until today, however, it was common to see 3D printing only as a complement to traditional manufacturing methods, either because of its speed when considering professional solutions, or its high price if industrial-level solutions are taken into account.

Raise3D is thrilled to announce a breakthrough technology that challenges all the existing limitations of FFF 3D Printing. It’s a breakthrough, it’s revolutionary, it’s a game-changer, it’s literally the next level for professional FFF 3D Printing, and Raise3D is truly excited about it!

Technology

In the wake of the development of high-speed for the RMF500, Raise3D managed to apply its learnings to its Pro3 series printers, achieving a speed 3.8 times faster than the current best professional printer available in the market.

The challenge was never to just instruct an FFF printer to print at a higher speed. Telling an FFF 3D printer to print at high speed is quite simple, and most manufacturers and users have tried it at some point. The challenge was to be able to do so in while keeping the same quality of layer adhesion and surface finish, in addition to the structural stability of the whole printer.

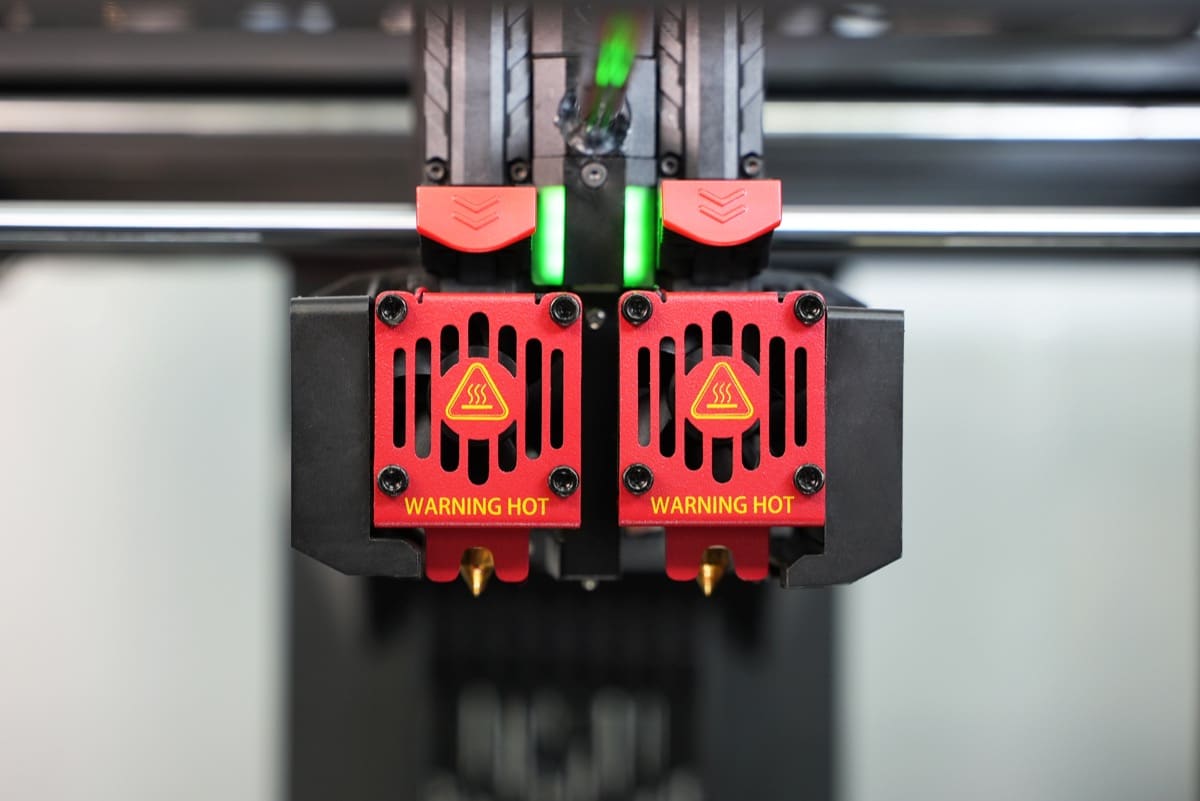

Raise3D can proudly reveal that its R&D team has achieved this goal, initially for its Pro3 series dual extrusion 3D printer, for which the whole of Raise3D’s ecosystem – hardware, software, and filament – had to be adapted.

The Pro3 Series’ strong and stable frame allows the printer to maintain high dimensional accuracy and excellent surface quality while running at extremely high acceleration and high speeds. Also, the Pro3’s advanced onboard processors allowed Raise3D’s R&D team to fully unleash the power of

innovative motion planning techniques, and process over 600,000 steps per second to implement an active vibration cancellation algorithm.

The hyper-speed solution is partially protected by Raise3D’s existing patents.

Competitive arena

Raise3D’s analysis of the current competitive arena in the professional market is that with the Hyper Speed Upgrade Kit, the Pro3 Series’ current lead in terms of technology becomes even clearer, and besides the already existing overall quality, it will undoubtedly be the fastest professional dual- extrusion printer on the market for some years.

This represents an opportunity for Raise3D to push the FFF market to the next level and to substantially increase its current customer base, which is needed in order to fulfill its ambitious development plan. For these reasons, it has been decided to make the Hyper Speed Upgrade Kit for the Pro3 Series, or HUK3 for short, available at an exceptionally affordable price until the end of the year.

Performance

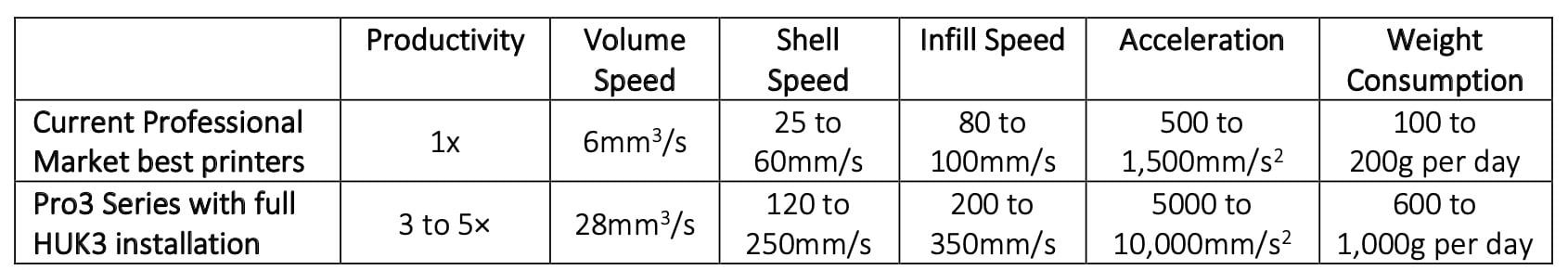

The results reached with the installation of the HUK3 on the Pro3 series, and the use of filaments from the high-speed line of filaments, are impressive and make it clearly stand out from all other professional printers:

Current Professional Market best printers Pro3 Series with full HUK3 installation.

Edward Feng, Raise3D’s global CEO, commented: “The results we’ve achieved with this technology breakthrough are truly remarkable, far better than we could anticipate, and makes us feel confident it will be a milestone, not only for Raise3D, but even for the whole FFF-based3D printing industry.” He added: “Our competitive superiority at a technological level has been increasingly recognized over the last years. With the HUK3 allowing customers’ ROI to multiply by more than 3 times, we now want to reach more than 3 times the customers we have so far, and have so decided to offer, until the end of the year, an exceptional price of almost 1/3 lower than the retail price planned for 2023.”

Filaments available

One of the challenges Raise3D faced while pushing for higher speed was the limitation coming from the filaments’ flowability.

In FFF, as it is known, the deposited material lines are fused by the residual heat of the material and the pressure of the moving nozzle. However, when the printing speed increases by a factor of 4, the filament has a very short time to melt from solid to a molten state, leaving the extruded material in a semi-molten state, with a hot shell and cold core, which can cause nozzle clogging and poor bonding quality between layers. Raise3D and their partners worked together to solve this challenge and is now launching two new filament lines for high-speed printing: the Hyper Speed and the Hyper Core.

The Hyper Speed is comprised of the more widespread filaments, while the Hyper Core is oriented towards more professional and industrial filaments, such as fiber-reinforced materials for industrial and end-use parts production and heavy-duty applications such as tooling, jigs & fixtures.

Both filament lines are optimized with balanced molecular weight and flowability, which allows them to have excellent interlayer bonding quality and Z-direction strength, a smooth surface quality, and absolutely zero warpage, making it perfectly suitable for many functional parts.

The Hyper Speed line will initially have available PLA and ABS, but other materials, like PETG, PC, ASA, and ESD-safe, among others, are already in the pipeline to be released.

Manufacturing on Demand

During 2023, the Hyper Core line will also launch its first filament, PPA CF, which is a carbon fiber-reinforced composite filament with superior heat resistance, strength, and stiffness.

To enhance the number of materials available for their customers, Raise3D will now invite filament manufacturers to join a specific new stage of their Open Filament Program (OFP), focused on high-speed filaments.

Additive productivity, ROI, and batch size

The application of the Hyper Speed Upgrade Kit to Pro3 series printers allows it to achieve a speed on average 3.8 times faster than the current best professional printer available in the market. From Raise3D’s calculations, the boost in productivity is such that 3D printing service providers may be able to pay back their investment in Pro3 series printers in a matter of weeks.

The increased productivity shall also have a substantial impact on traditional manufacturing processes, like injection molding and CNC, in particular when the part produced may be subject to frequent or regular design changes.

With an increased productivity of over 3 times, the all-in cost of a Pro3 series printer becomes extremely affordable when compared to the usual price of even just the tooling required in other manufacturing processes. This, together with the full flexibility provided by additive manufacturing, now makes FFF 3D printing very competitive as a manufacturing method, even for sizeable batches and will make print farms / print factories more and more common.

Sales process

The HUK3 is available to all customers who already have or will purchase Pro3 series printers and can be purchased directly from Raise3D’s website (www.raise3d.com) for customers based in the USA, or from any Raise3D’s authorized resellers for customers based in Europe or in the Rest of the World (Find a Reseller (Europe) or Find a Reseller (Rest of the World)).

Once the purchase is made, the authorized reseller will provide a link for a Raise3D page where the customer can access a software update and receive the installation instructions for the hardware.

If the purchase is made until the end of 2022, an exceptional offer is available.

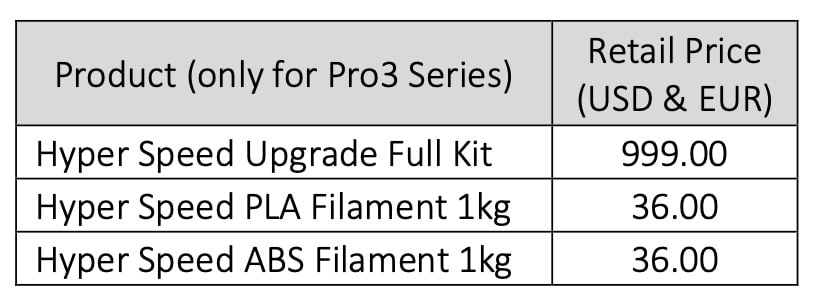

Pricing

The HUK3 includes software upgrades, 2 high-flowrate Pro3 hot ends, a smart auto frequency calibrator, a spool of Hyper Speed PLA, and a spool of Hyper Speed ABS.

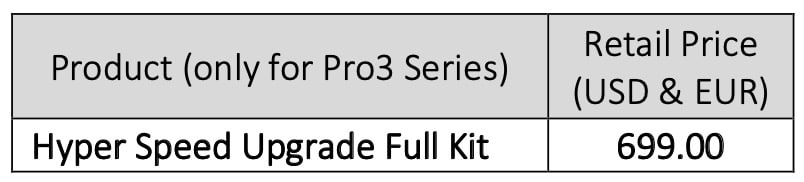

The prices of the HUK3 and the filaments for US and EU are listed below. In other territories, prices may differ.

For customers who already own Pro3 series printer(s) or will purchase it and the HUK3 until December 31st, 2022, the following exceptional offer for HUK3 will apply.

Future

The Hyper Speed will also be available for the RMF500, the industrial printer developed for Fast Production of Large composite End-use Parts, and Raise3D is now also working to make it available for the other printers in their portfolio that have the same mechanics as the Pro3 series.

Webpage, launch event and showcase

Raise3D invites everyone to visit their Hyper FFF webpage (Hyper FFF US and Rest of the World, Hyper FFF Europe] and learn all about hyper-speed technology and how it will bring FFF professional 3D printing to the next level.

Also, at 10:00 CET (1:00 PST) on November 10th, 2022, Raise3D will release the video of a virtual launch event where you will learn everything you need to know about this new breakthrough in 3D printing. The launch event video will be available on Raise3D’s official YouTube channel, as well as on the Hyper FFFTM webpage mentioned above.

For those who may also want to see and experience the Hyper Speed live, Raise3D welcomes them in their booth (Hall 12.1, Booth C10) at Formnext 2022, from November 15th to 18th.

Interviews and other questions

If you have any questions or would like to arrange an interview with Edward Feng, Raise3D’s Global CEO, please contact Nadia Yaakoubi (email: nadia.yaakoubi@raise3d.eu).

You might also like:

Quantica introduces the NovoJet C-7 multi-material desktop system: NovoJet C-7 is an open printing platform, well-suited for 2D and 3D application development. The printer was created for research institutes, R&D labs, and other organizations looking to develop new additive manufacturing materials and workflows. Beyond feasibility testing and application development, the printer can also be used for customized, low-volume production – enabling a seamless transition from lab to production.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment