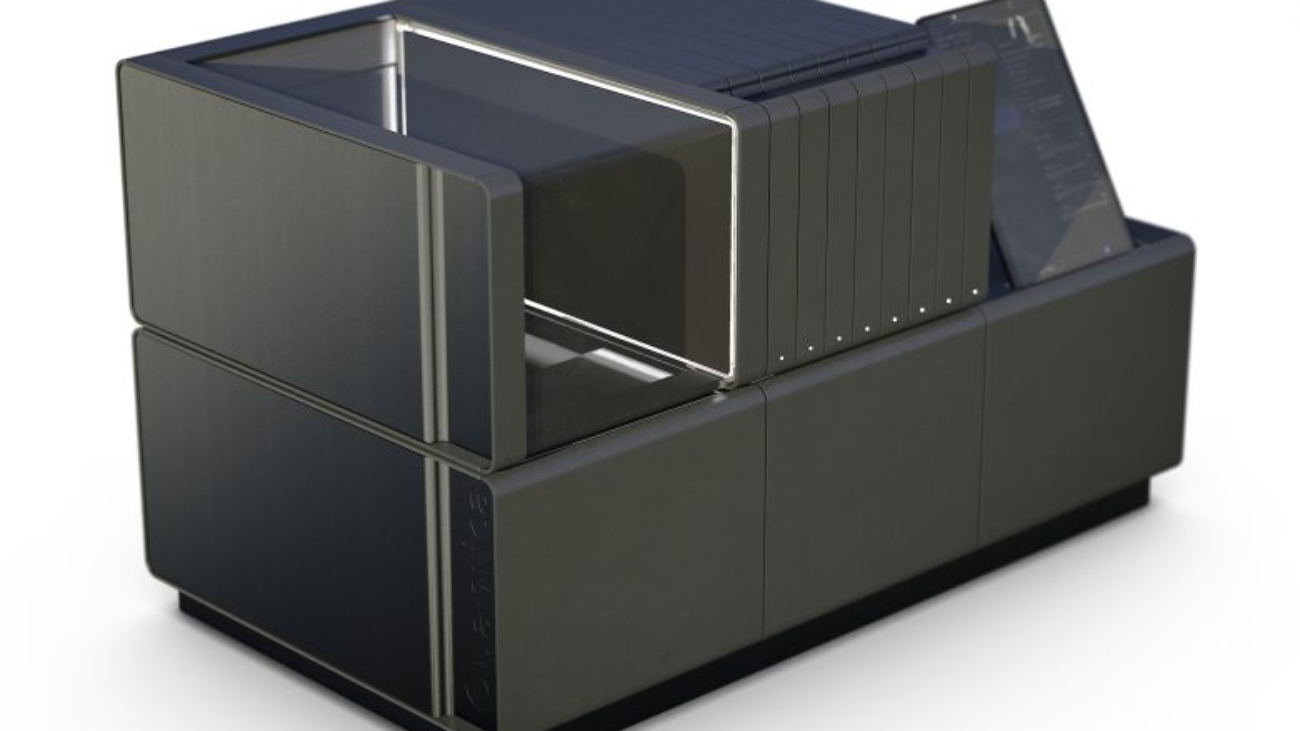

Last year at Formnext, Quantica announced its T1 Pro, an R&D system that showcased the company’s multi-material, ultra-high viscosity jetting capabilities, known as NovoJet. This year, Quantica will be back at Formnext 2022, introducing the company’s new Desktop system – the NovoJet C-7.

NovoJet C-7 is an open printing platform, well-suited for 2D and 3D application development. The printer was created for research institutes, R&D labs, and other organizations looking to develop new additive manufacturing materials and workflows. Beyond feasibility testing and application development, the printer can also be used for customized, low-volume production – enabling a seamless transition from lab to production.

With the NovoJet C-7, users are able to experiment with materials, thanks to the system’s ability to handle a wide range of fluids, with viscosities exceeding 380mPa•s at jetting temperature – equating to approximately 4000mPa•s at ambient temperature, in addition to experimenting with liquids with high particle loading.

Manufacturing on Demand

The multi-material system also allows for new material combinations, and can control up to seven material channels – giving users access to new material combinations with better mechanical properties, color fidelity, and aesthetics, and can be customized for research and development needs.

The power of Quantica’s NovoJet printhead technology is its ability to print materials that are 15x more viscous than legacy inkjet printheads – opening new possibilities for delivering high-value, end-part products with properties such as high-toughness, temperature resistance, conductivity, biocompatibility, and flexibility.

Multiple industry partners, mainly within the dental, medical, and electronics space, have begun collaborating with Quantica to develop targeted solutions based on the novel capabilities.

“This new system unlocks enormous possibilities for the material deposition industries, giving material developers the ability to move past the limitations of low-performance fluids and start developing new formulations with better properties of interest. In the end, we empower organizations to build products in new and exciting ways,” said Ramon Borrell, CTO of Quantica. “Quantica is already exploring several applications in the dental, healthcare, consumer goods, and electronics industries. We are excited to support these, and the many other, industries in breaking down current inkjet barriers and limitations.”

You might also like:

Additive productivity: a new era in FFF professional 3D printing: The gradual adoption of FFF 3D printing has shown that, regardless of its speed, it can be the most competitive manufacturing method to produce prototypes, customize products, meet individual needs, and to carry out small batch production.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment