Dyndrite launches Additive Manufacturing Toolkit, forms new partnerships AM Software

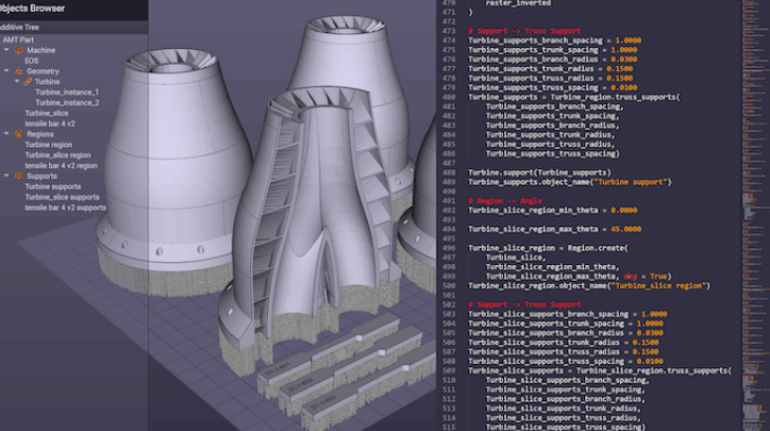

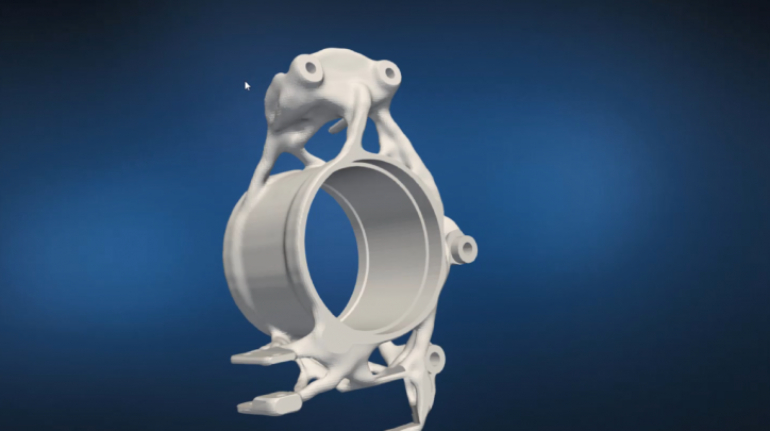

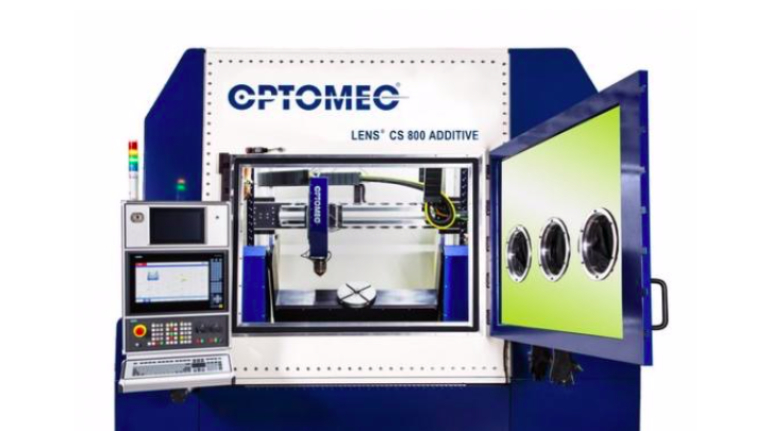

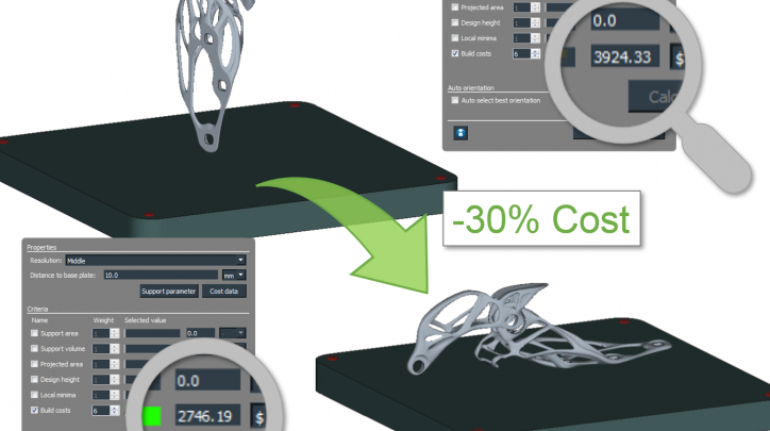

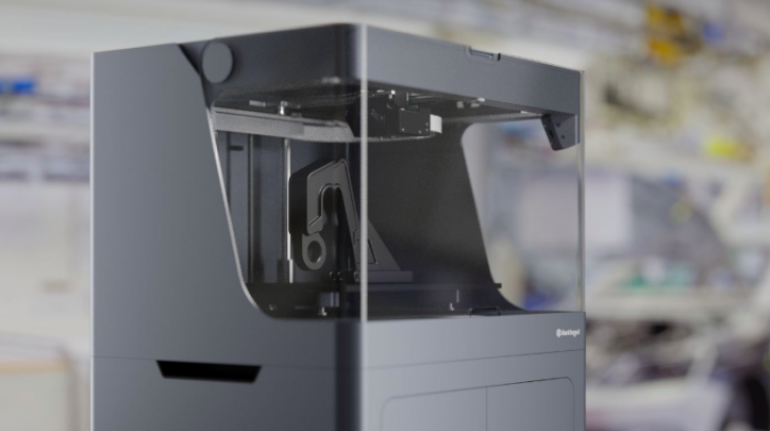

AM software developer Dyndrite Corporation has unveiled its Additive Manufacturing Toolkit (AMT) and accelerated production preparation build processor for 3D printing, which has the potential to improve performance and native CAD-to-print capabilities for AM users. In addition to presenting the software solution at Formnext, the company has announced a series of industry partnerships with EOS, Renishaw and others.