HP to launch new commercial HP Jet Fusion 5400 series 3D Printer Hardware

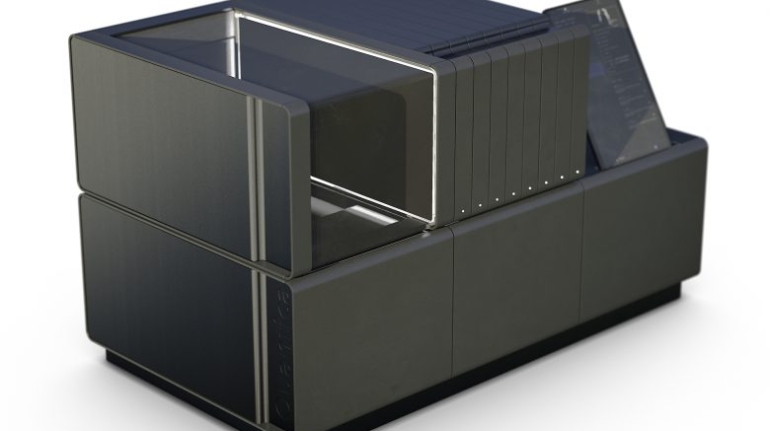

This week at Formnext, the world’s largest additive manufacturing event, HP is showcasing its new commercial Jet Fusion and Metal Jet 3D printing solutions, new post-processing capabilities, expanded Digital Manufacturing Network (DMN), new materials and recycling program, and a variety of industrial production applications. The show marks the first time HP is publicly exhibiting its new HP Jet Fusion 5420W Solution including white applications, and the full modular HP Metal Jet S100 Solution including a new John Deere production application.