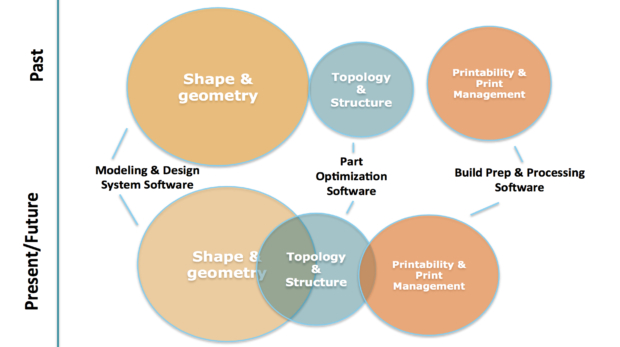

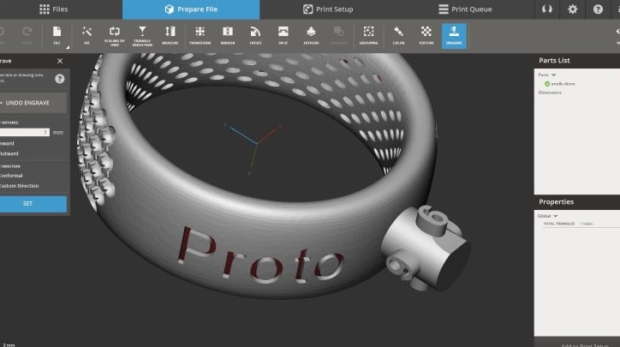

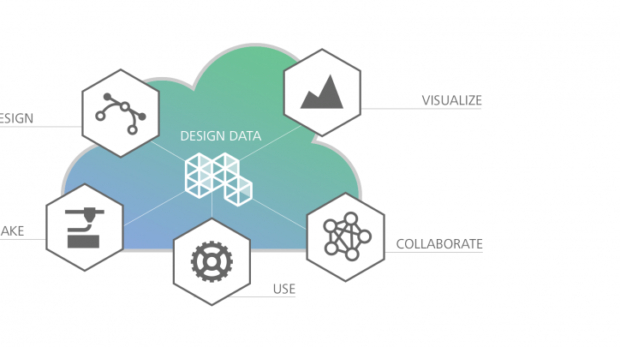

After spending a bulk of the last few years developing one of the most powerful and all-encompassing 3D printing cloud services on the entire market, 3DPrinterOS seems prepared to unleash their platform to the global 3D printing community. This week, the Silicon Valley-based company 3DPrinterOS announced that they would expanding their cloud operating platform on a global level by moving their service to Microsoft Azure, which is an open, flexible, professional-grade cloud computing platform. The recent move to Microsoft should certainly help 3DPrinterOS garner some much-deserved attention, as their cloud infrastructure is already utilized by the likes of Ford, Cisco, Duke University, CalTech, and many other businesses and educational institutions. Focused on integrating their platform into universities and enterprises around the globe, Microsoft Azure seems to be the optimal choice for the 3DPrinterOS platform. “We are extremely excited to collaborate with Microsoft Azure to serve our Enterprise Clients with its highly secure, hyper-scale global cloud,” said 3DPrinterOS CEO John Dogru. “It was a challenge to find the right company that had the cloud infrastructure, compliance, security, and reliability around the world including countries like China and Europe.” So, those who are unfamiliar with the cloud service may be asking, what exactly does the 3DPrinterOS platform do? Well, in all honesty, it’d be much easier to explain what it doesn’t do. Their virtual factory enhances the entire 3D printing process, all the way from the CAD file to the print bed. By offering a centralized workflow, anyone from IT managers to students can manage a wide-range of 3D printers and designs directly from a web-based browser or through the 3DPrinterOS smartphone app. On Azure’s secure and globally connected network, the 3DPrinterOS platform will be able to continue providing customers with an efficient way to manage up to 1000’s of networked 3D printers, users, and designs, essentially revolutionizing the fragmented world of 3D printing software, which oftentimes requires a handful of different programs and processes to complete one goal. But, with 3DPrinterOS, users are able to manage every part of the 3D printing process from where ever they happen to be, and are able to instantly change print settings, watch a live-stream of the many print jobs taking place from their smartphone, and even use the built-in slicer and instantaneously queue up a new print on the fly. “The cloud is transforming entire industries and creating new opportunities for even the most innovative new businesses,” said Senior Director of Microsoft Azure, Nicole Herskowitz. “The market leading scale and speed of Microsoft Azure helps spur global growth opportunities for companies like 3DPrinterOS who are utilizing cloud computing and IoT connected devices in a completely new model of decentralized manufacturing.” Over the last eight months, the 3DPrinterOS cloud platform has unleashed decentralized manufacturing, building over 62,000 parts in 100 different countries. With this latest move to Microsoft Azure, the future looks extremely promising for 3DPrinterOS, who are taking the limitless and relatively cloud platform and creating the powerful 3D printing management platform that the industry has been in desperate need for. As they continue to expand into universities and enterprises throughout the world, 3DPrinterOS is simplifying the time-consuming and currently fractured 3D printing process, cutting out the middle man and handling everything that happens in between the CAD file and print bed.