Taking AM From Niche to Mass Adoption through Effective Continental Trade Shows Additive Manufacturing

From the UK, through Germany, to Barcelona. If the biggest limit to a real, widespread adoption of additive manufacturing is industry awareness, trade shows are one of the most effective ways to address it. AM-centric trade shows also need to be able to reach out to companies looking to AM as a solution to real manufacturing challenges, not just a way for AM system and materials manufacturers to confront each other.

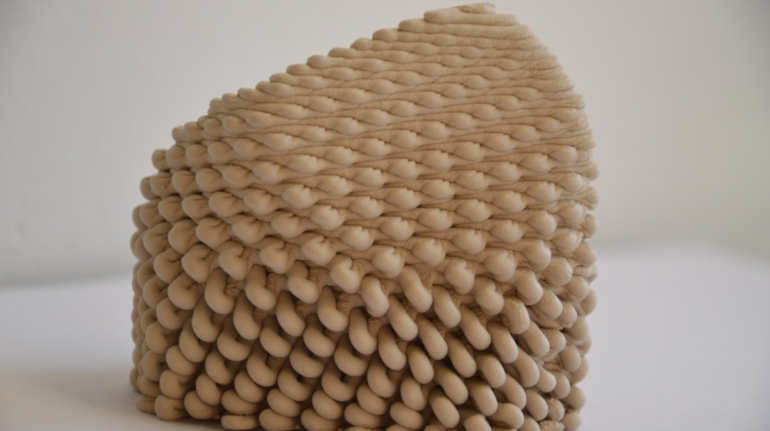

![EnvisionTEC launches new E-Shore A Material for 3D printed footwear [video] Consumer Products EnvisionTEC launches new E-Shore A Material for 3D printed footwear [video] Consumer Products](https://facfox.com/wp-content/uploads/orderfile/image/2020/11/ERrIja.jpg)