Thermwood Company, an Indiana-based company that develops, produces and sells technology-based products, recently demonstrated its ability to manufacture large-scale additive manufacturing (LSAM) through 3D printed yacht hull molds measuring 51 feet. It shows the situation where only one mold is needed to make a large boat (such as a yacht).

This is what Thermwood calls a new method of mass production.

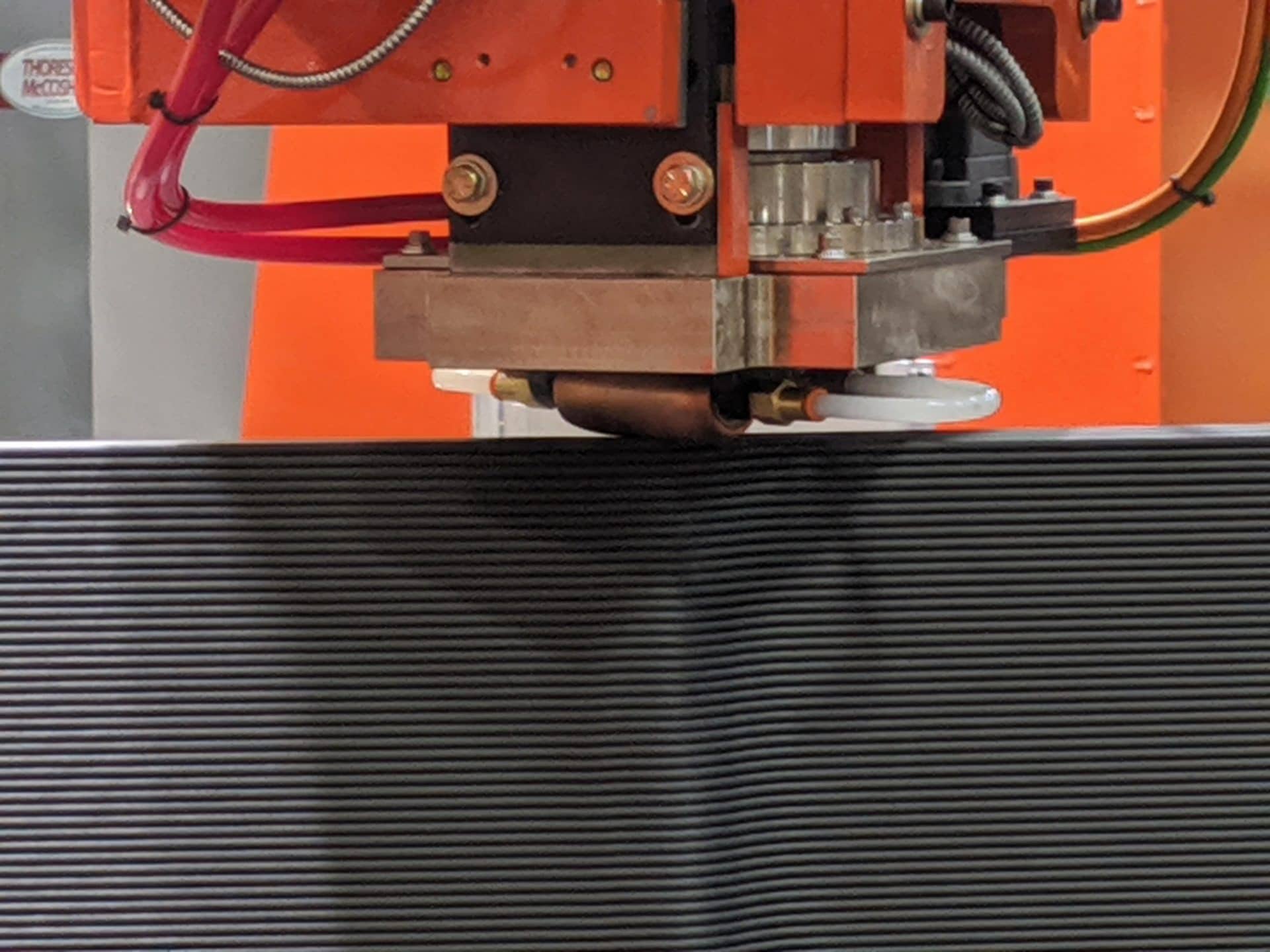

The 3D printed yacht section of the test mold is made of Techmer PM’s carbon fiber reinforced ABS. ABS was chosen because of its physical properties and lower cost compared with other reinforced thermoplastics.

3D printed yachts – journey deadline

Thermwood has already 3D printed a full-scale cruise ship master pattern, which has been used to produce multiple production hull molds. Although this proves the value of additive manufacturing of small boat tools, large ships (such as yachts) requires a different approach. In these cases, since only a single mold is required, it is desirable to print the mold itself instead of printing the plug or pattern from which multiple production molds can be made.

In order to show the industry how the 3D printed yacht mold works, Thermwood printed a 10-foot section from a 51-foot-long yacht hull mold. This rather unique mold design was specifically developed for additive manufacturing. It is printed in sections, each about five feet tall. Then use high-strength polymer cables to chemically and mechanically combine these 3D printed parts and divide them into two halves. The two mold halves are then bolted together to form a complete master mold for the yacht hull.

The demonstration

The process of 3D printing a yacht

There are several interesting aspects to this design. First, each mold part has a shaped rocker. After the mold is fully assembled, it is placed on the floor of these rockers. At this point, the mold can be turned over to tilt about 45 degrees to the left and right, just like a huge rocking chair. This makes it easier to access during the stacking process. A set of molded wedges are clamped to the rocker to hold the mold in the desired position. After the hull is laid and fully cured, the mold is rolled to a horizontal position, and the printed wedges are clamped on both sides to keep it level. Then the two mold sides can be loosened and slid apart to release the finished hull.

Thermwood’s 3D printed test pieces show that this method of 3D printing yacht hull molds will work in practice. The printed part of the test mold is made of carbon fiber reinforced ABS from Techmer PM. ABS was chosen because of its physical properties and lower cost compared with other reinforced thermoplastics.

Some thermoset materials can work directly on the ABS molding surface using only traditional demolding methods, but other thermoset materials are based on solvents that can chemically attack the ABS polymer.

To prevent this, Thermwood has tried several protective coatings, including traditional anti-mold gel coatings. Although practically all tested coatings work at room temperature, large thermoset molds usually receive a certain amount of heat due to the exothermic reaction that occurs during the thermoset curing process. Thermwood tested each coating at 200 o F and found that some of them work well at room temperature and high temperature, while others work well at high temperature at room temperature.

Although this approach seems to be available today for certain thermoset plastics, the ideal approach is to develop a low-cost polymer that is chemically resistant to other thermoset solvents and does not require a protective coating.

Fine details

These demos were printed and finished on Thermwood’s 10 x 10 foot LSAM MT, which is the smallest and lowest cost additive manufacturing system currently available for Thermwood. The entire mold part is composed of four printed parts, weighing 4,012 pounds, and printing time is 65.5 hours. The original idea was to use it as the core of the Thermwood Additive Manufacturing trade show display, however, due to the cancellation of the trade show, it has become the main exhibition for Thermwood visitors and potential customers.

Bottom line

In short, the answer is yes, we can 3D print large yacht hull molds. The Thermwood demonstration showed that if you need very large parts, you don’t necessarily need very large machines. With a little imagination and some creative engineering, very large structures can be manufactured, even on smaller, lower-cost additive manufacturing systems. Although the size of LSAM MT is not small, it does meet the needs of many companies who want to make larger parts but cannot fully handle Thermwood’s large systems.