Originated in Japan, the fashion toys market has grown rapidly in China in the past few years, from 6.3 billion yuan in 2015 to 20.7 billion yuan in 2019, with a compound annual growth rate of 34.6%. Its sub-categories mainly include: blind box toys, figures, art toys, BJD toys (Ball-jointed Doll, also known as ball joint dolls), adult assembled toys, GK figure kits (unpainted garage kits) and so on. The fast-developing anime culture and 3D printing technology are expected to drive the rapid growth of the fashion toy market. Here’s the story of 3D printing and fashion toys, and how FacFox is involved.

Duties

Let’s make it clear what are designer’s duties and what FacFox does. The whole process of making fashion designer toys goes like this.

Inspiration collection and design

Inspiration is the basis of the background setting, customers love to know the stories of the toys and how they are created. The designers will find inspirations from many websites, draw a lot of versions of drafts, and then exclude the ones that lack originality.

3D modeling and rendering

In short, modeling is to transform a 2D sketch into a 3D model, which is conducive to the control of details from all angles.

Of course, because it needs physical manufacture in the end, it involves whether the model can be smoothly produced. There will be a long model revision and color matching process.

During this part, the designers will need our help. Sometimes our modelers will help them build 3D models. If the clients can do it themselves, we will examine the models thoroughly and point out the problem with prototyping and batch production. The designers will take our advice to avoid high-risk structures and reduce production costs.

Prototyping and low-volume production

Those who pay attention to the blind box toys may know what are the red, white and grey garage kits.

We generally print the heads with DLP Ultra Detail Resin, which is red; and print the main bodies with SLA Durable Resin, which is white.

Before printing, we will spray putties onto the models to examine printing issues and make adjustments. Those are what we called grey models.

Mass production

Grey and white garage kits actually need to be opened, that is to say, we have entered the mass production link. We will have two batches of color testing before the finished product, but we are not sure if there are others.

After the four steps, a blind box fashion toy was finally born. We, together with the designer and the modelers, are responsible for making high-quality toys.

Technology

At present, in the field of light curing, FacFox mainly introduces two solutions, DLP and SLA printing technologies. We usually combine them together, printing the head with DLP technology, and printing the body with SLA technology.

DLP 3D Printing:

- Application: The head or whole body of the action figures has high requirements on skin and hair.

- Advantage: Pay more attention to detail performance. The prints would have a smooth surface and excellent textures.

- Build volume: 192 x 120 x 180 mm

SLA 3D Printing:

- Application: The main body, base, costume, and props of blind box toys and action figures.

- Advantage: Compared with DLP, SLA has significant advantages in terms of printing speed, build volume, etc. It can print larger format.

- Build volume: 1700 x 800 x 600 mm

Toy

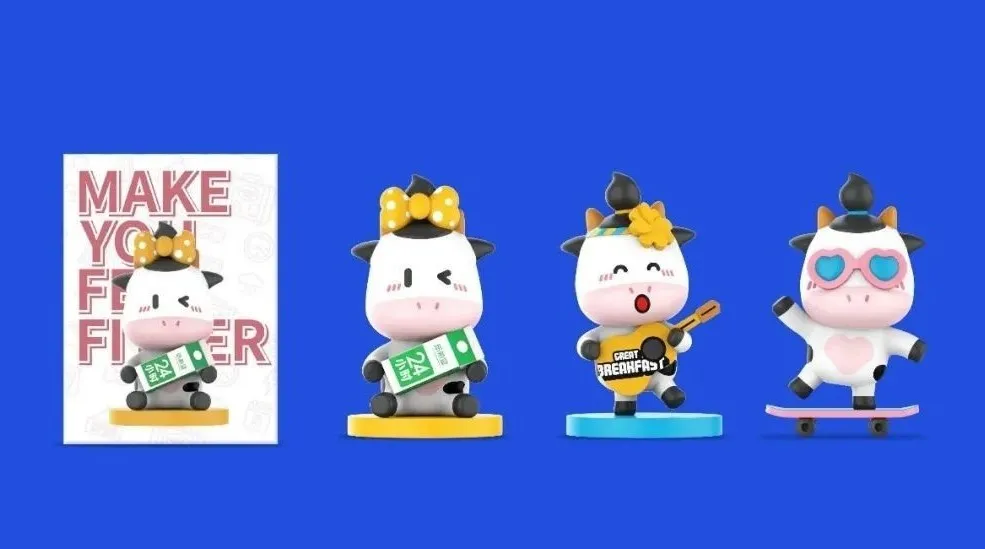

Mass-produced 10cm-high blind box toys

The blind box toys with a height of 10-15cm are the best-selling on the market. It has the characteristics of fast response time, timely production, and keeping up with hot trending IPs.

The industry’s pain points include the complex mold opening process and long development cycle. 3D printing can effectively optimize the traditional process, replace the clay molding technique of prototyping, reduce costs, and shorten the creative cycle.

Process

- 3D printing.

- Mold making and batch production with injection molding, urethane casting, electroplating, etc.

- Model revision

- Painting

- Packing

Advantage

1. The traditional clay modeling craftsmanship is also a kind of constantly revised creation. 3D printing enables the creation and modification to become easy and low-cost in the first stage.

2. The traditional process takes about 6 months to complete the first batch of finished products, while 3D printing can help shorten the process to 3 months.

3. Some models need to be split into different parts for mass production. 3D printing technology directly completes the decomposition in the software.

4. Reduce the number of mold making and significantly reduce costs.

5. Data can be scaled and processed repeatedly.

Low-volume produced 25cm-high action figures

When the height of the figure exceeds 25cm, the market has changed a lot. 3D printers can help designers further optimize the process, greatly shorten the development cycle and reduce mold-making pains.

Process

- 3D printing

- Urethane casting

- Model revision

- Painting

- Packing

Advantage

- Can directly print less than 5 pieces with 3D printing technology.

- Allow for printing hollowed models and injecting the resin inside.

- Greatly shorten the development cycle.

- Greatly expand the business patterns such as pre-sales and customization.

Material

For fashion toys 3D printing, high-temperature resistant, moisture-resistant, water-resistant photosensitive resin materials that can present excellent surface quality and perfect details are preferred.

The photosensitive resin is composed of two major parts, namely photoinitiator and resin. Resin is composed of prepolymer, diluent, and a small number of additives.

The amount of photoinitiator and diluent has an important influence on the curing speed and curing quality of the photosensitive resin. When the proportion of photoinitiator and diluent is appropriate, not only the curing speed is fast, but the curing quality is also better.

FacFox always insists to buy the most high-performance materials and is experienced in prepare the compound.

Future

The integration of 3D printing technology and the animation industry will help the fashion toys industry complete a revolutionary upgrade.

The pace of development of the times has never stopped. At the animation exhibition in recent years, we strongly felt that there are more and more 3D printed masterpieces and the market is becoming more mature.

Here is our vision for the future.

1. Differentiated low-volume rapid response and flexible production.

2. Distributed manufacturing and intelligent production management.

3. Material breakthroughs that can replace traditional materials.

4. Meet the needs of diversified markets, and meet the industry’s special technical support needs for multi-color printing, stop motion animation, soft models, intelligent models, etc.

Leave A Comment