We have seen that 3D printed robots can perform many tasks, from tattooing a person’s arm and gong to vacuuming, building a house, and mowing the lawn. But robots capable of performing complex movements (such as jumping, walking, and navigating in different types of terrain) are either too expensive or too simple to do many things. But a new open-source robot can change this.

Researchers from the NYU Tandon School of Engineering, its Machines in Motion Laboratory, and Germany’s Max Planck Institute for Intelligent Systems (MPI-IS), collaborated to create a quadruped robot, named Solo 8, that’s roughly the size of a dog, quick and easy to assemble, comparatively low-cost, and not at all creepy. But the best thing about the robot is that it is open-source, which means other research laboratories can easily copy and modify it.

Ludovic Righetti, Associate Professor of Electrical and Computer Engineering and Mechanical and Aerospace Engineering at New York University Danden, led the Solo 8 Collaboration Group, whose mission is to make the teaching and research of robotics more convenient. With the support of the Open Dynamic Robot Initiative, Righetti and MPI-IS researchers Felix Grimminger and Alexander Badri-Spröwitz started the project in 2016 with funding from Righetti’s ERC initial funding.

To date, papers on their work have recently been published at the Virtual International Conference on Robotics and Automation (ICRA) and have been published in the Journal of Robotics and Automation Letters.

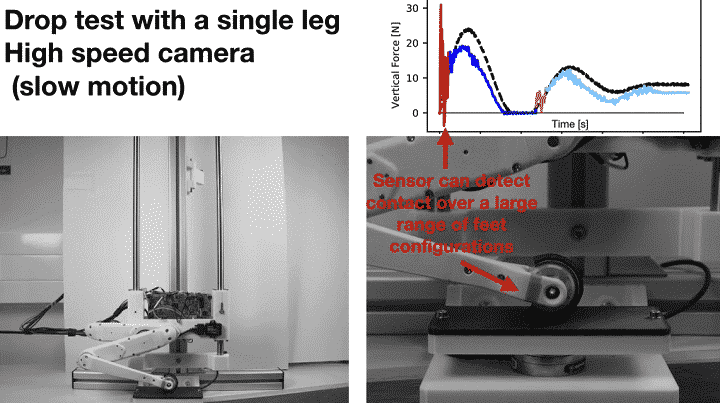

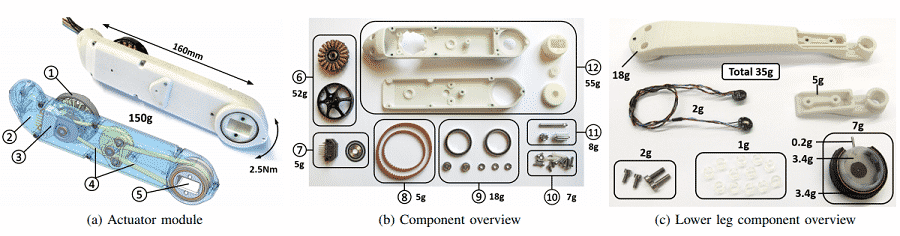

“We present a new open-source torque-controlled legged robot system, with a low-cost and low-complexity actuator module at its core,” the abstract states. “We also present a novel foot contact sensor suitable for legged locomotion with hard impacts. A 2.2 kg quadruped robot with a large range of motion is assembled from eight identical actuator modules and four lower legs with foot contact sensors. Leveraging standard plastic 3D printing and off-the-shelf parts results in a lightweight and inexpensive robot, allowing for rapid distribution and duplication within the research community.”

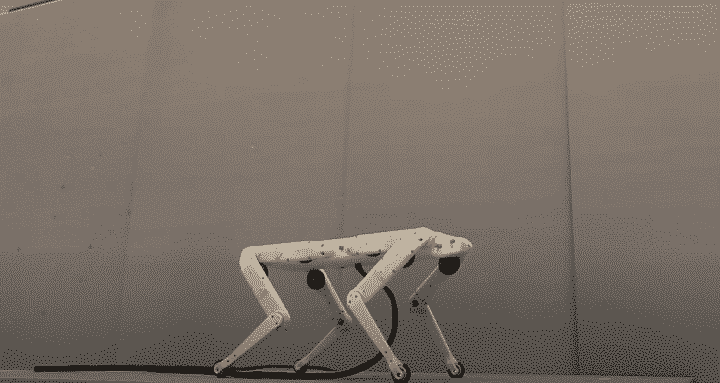

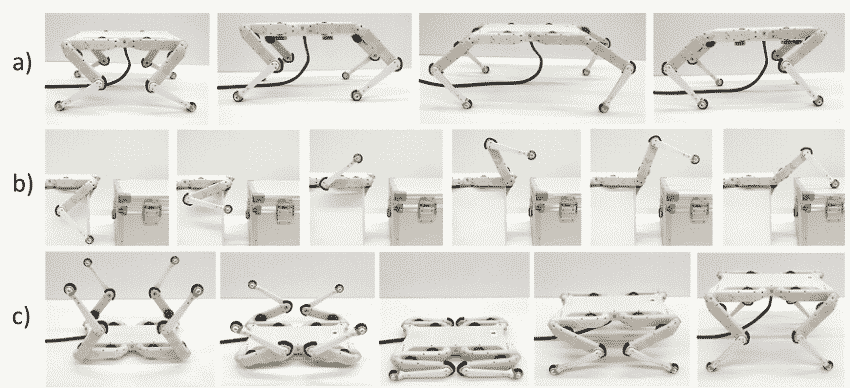

Solo 8 is like a more expensive robot: its driving joints and torque-controlled motors allow it to walk in multiple directions, jump and pick itself up when it falls.

“Solo has some novel capabilities that we are interested to explore in the future. It has an extensive range of motion, for example,” Grimminger stated. “When the robot falls on its back, it can configure the legs the other way and just stand up. Or it can jump up to reach 65 cm from a standing height of 24 cm.”

The Solo 8 weighs just over 2 kg, and has a higher power-to-weight ratio than most other quadruped robots, which makes it safer and easier to operate in the laboratory, and can even be placed in a backpack. All of its components are available for purchase or 3D printing, and the team has provided the build files for free on GitHub under the BSD 3 terms license. The team’s decision to design the robot as an open-source platform will benefit other researchers because they will be able to collect and share data from their own experiments to make faster progress in robotics.

Righetti said, “Already many universities have approached us, and wish to make a copy of our robot and use it as a research platform.”

An example is the empirical reasoning department of MPI-IS, which uses this platform to develop robot fingers that can manipulate objects. Other potential research areas include extremely dynamic sports, such as parkour behavior. The investigation is based on animal limb movements; environmental manipulations, such as buttons; integration of robots with advanced communication technologies; and reinforcement learning for dynamic and complex behaviors.

“Our robot platform is a great base to quickly prototype and build high-performance hardware. In return we benefit, because other researchers can contribute to the project; for example colleagues at the LAAS-CNRS in France have developed an electronic board to help communicate with the robot over WiFi. Also, complex control and learning algorithms can be rapidly tested on the platform, decreasing the time from idea to experimental validation,” Righetti explained. “It greatly simplifies our research, and our open-source approach allows us to compare algorithms with other laboratories. In my lab here in New York, we have developed very efficient motion optimization algorithms, but testing them on a complex, heavy robot can easily take half a year of work for several researchers, while this can be done more easily with Solo. That was a big deal for us.”

So, how does the team create Solo 8? Badri-Spröwitz said that this requires “extensive expertise” and several years of hard work:

“Our platform is the combined knowledge of several teams. Now any lab worldwide can go online, download the files and print the parts, and buy the remaining components from the catalog. And everybody can add extra features, within a few extra weeks. Done – you’ve got yourself a world-class robot.”

However, all of this work has paid off. As Badri-Spröwitz estimates, other research teams can easily create their own Solo 8 version for only a few thousand euros. The robot is named after its eight movable joints, which allow each leg to change its length and angle. However, the tests conducted on the latest version of the robot are three degrees of freedom per leg, for a total of twelve. This makes it more versatile and enables more complex behaviors, such as walking sideways.

It also has a torque-controlled motor, which functions like elastic tendons and muscles of animal legs-this allows Solo 8 to move in a “spring-like behavior”.

“Please note that the robot uses a virtual spring instead of a mechanical spring. As a virtual spring, it can be programmed,” Badri-Spröwitz explained. “For example, you can adjust the stiffness of the spring from soft to hard, which is interesting because we see the stiffness of humans and animals change, and by adjusting the stiffness, the robot can achieve adaptive and robust motion behavior.”

Open source projects like this are indeed in the spirit of the maker community-by sharing our knowledge with others instead of keeping it to ourselves, we can work together to achieve great achievements and even save lives.