Materialise Kickstarts the New Generation of Custom AM Insoles

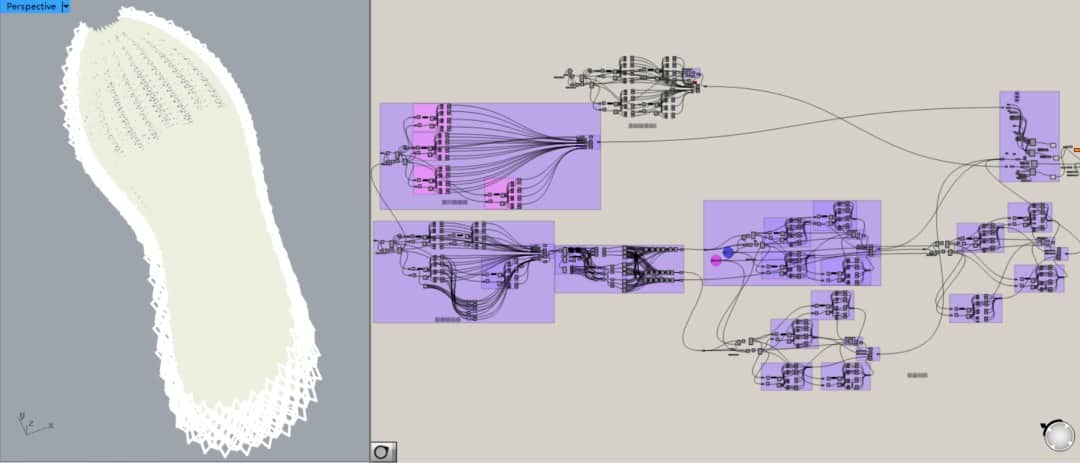

The Materialise Phits Suite is a new standard of personalized care program that helps improve patient mobility. After decades of experience in gait analysis and 3D technology, Materialise wants to start the next generation of insoles, leveraging the latest digital path capture technology, advanced analysis software and 3D printing to achieve a more accurate, efficient and fully customizable workflow. The Materialise Phits Suite is a digital toolbox for accurate and efficient end-to-end workflow, that can assist in providing patient counseling, care, and treatment.