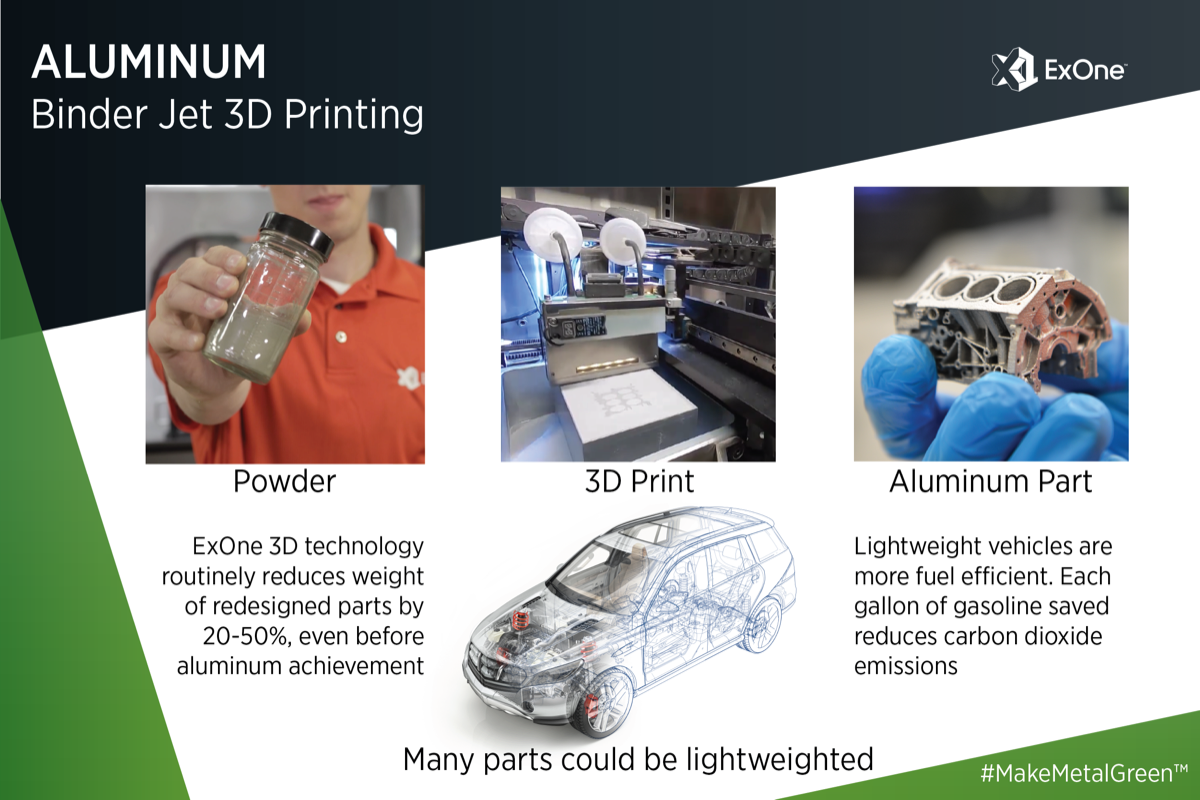

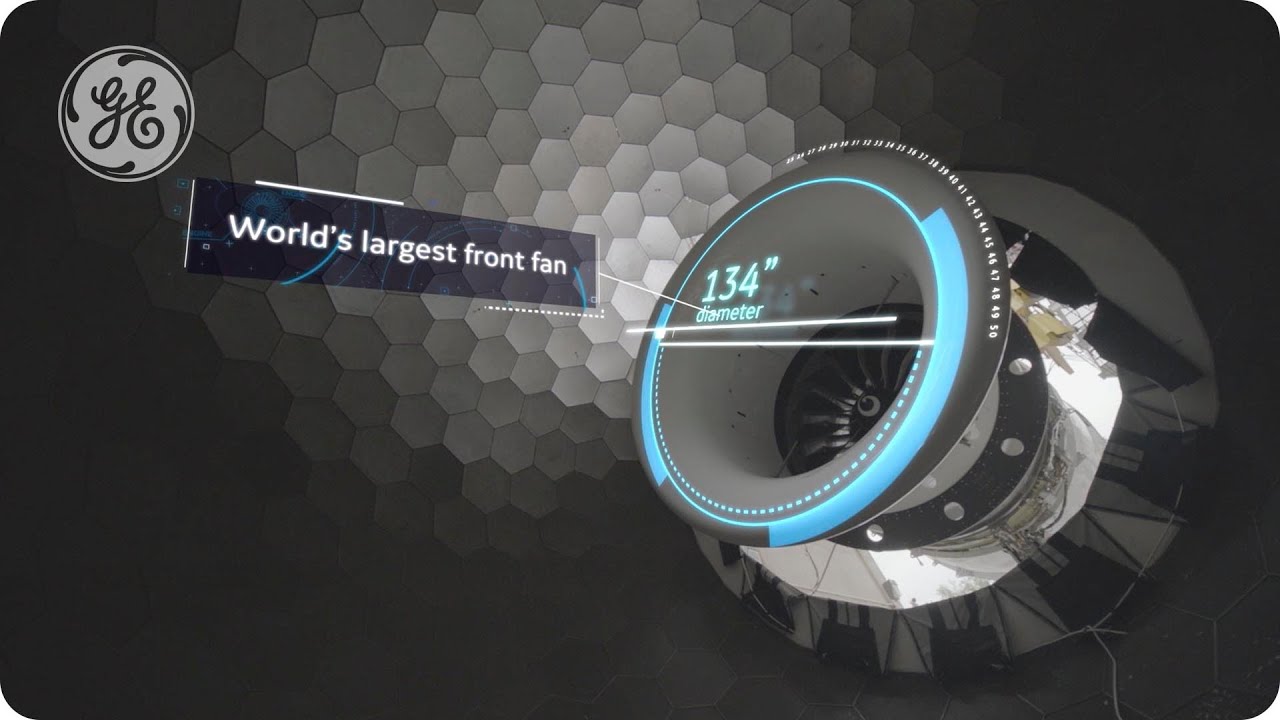

APWorks and SAP aim to transform the manufacturing supply chain with 3D Printing. The fully owned Airbus subsidiary – which has been experimenting with the state of the art in AM – announced the signing of a co-innovation agreement with german enterprise software giant SAP, which aims to accelerate the adoption and standardization of industrial 3D printing initiatives for the aerospace and defense industry. This announcement was made at the Farnborough International Airshow being held July 11– 17 in Hampshire, England. APWorks will to use the 3D printing services recently announced by SAP to operate a bionics network that connects 3D printing experts and end users. These services will allow APWorks to manufacture 3D printed components such as armrests and brackets, improve fuel efficiency and reduce CO2 emissions. “The ability to 3D print all the possible components of an A350 aircraft could reduce the weight of it by nearly a ton,” said Joachim Zettler, CEO of APWorks. “On-demand 3D printing cloud service from SAP can help us to develop our vision for distributed, on-demand production of aerospace components and still meet the high quality standards necessary to make the aircraft fly.” APWorks can also better manage spare part orders in real time to deliver qualified products for safety-critical applications in aerospace and other industries. The co-innovation agreement between SAP and APWorks plans to address the following areas: • Digitalization and simplification of the production part approval process • Screening and validating parts for using the 3D printing process • Designing and redesigning of a part or system to optimize for on-demand manufacturing and 3D printing • Accelerating and standardizing the processes for certifying the manufacturing of parts by 3D printing firms • Securing an on-demand budgetary price for manufacturing firms to evaluate 3D printing parts versus traditional manufacturing, including cost components such as tax and warehousing, using the SAP® Product Lifecycle Costing solution • Covering each stage from production floor to customer door — for seamless routing of the order 3D printing is now moving beyond industrial prototyping and into manufacturing industries using multiple materials including metals, plastics and ceramics, which is helping to reinvent the manufacturing supply chain.