Stratasys Ltd. (NASDAQ: SSYS), a leader in polymer 3D printing solutions, is launching the first 3D printer designed specifically to 3D print on fabric, in a direct-to-textile mode. The Stratasys J850 TechStyle 3D printer, the company’s newest PolyJet printer, is being launched during an exclusive event at Milan Design Week’s Fuorisalone to meet the unique needs of design and fashion manufacturers, which include 3D printing for high-end, premium textiles and clothing, bags and accessories and footwear.

Stratasys is providing designers and fashion brands with the ability to differentiate their manufacturing practices through the unique versatility and productivity of the Stratasys 3DFashion solution which includes the J850 TechStyle 3D printer, workflow software and materials that support the individual needs of fashion manufacturers. This solution opens unlimited possibilities for fashion manufacturers to personalize and customize 3D-printed fabric pieces – including limited editions and digital automation, all while reducing time-to-market and ensuring mindful manufacturing™.

Lidewij Edelkoort, world-renowned fashion specialist and trend forecaster, said there has long been interested in a 3D printer for fabric and garments, with countless potential creative applications for fashion designers. She expects an enthusiastic industry response as a result, saying; “From decorative craft to creative engineering comes this hybrid machine from Stratasys, as an answer to a million prayers, allowing the ascension of embellishment for an inclusive following”.

To further extend the reach of the J850 TechStyle 3D printer, Stratasys has joined forces with a series of partners including, Dyloan and the D-house in Milan, along with Dyloan’s in-house 3D printing service Shapemode. A top innovation center of excellence for evolving fashion technology, D-house demonstrates the versatility of 3D printing applications from concept design through production using Stratasys 3DFashion technology.

“As far back as 2019, I predicted that in just a couple years we would see 3D printing incorporated into high-end fashion houses,” said Stratasys Art, Design and Fashion Director Naomi Kaempfer. “That time is here. We learned and modified those early designs, and created a new, dedicated printer using 3DFashion technology that is allowing fashion designers to create without limits. This is just the beginning of the journey as we continue to evolve this technology and pioneer new fashion design innovations.”

Manufacturing on Demand

The J850 TechStyle 3D printer is designed to print directly on a variety of fabrics and garments, including denim, cotton, polyester, linen and leather at volumes ranging from single pieces to the tens of thousands.

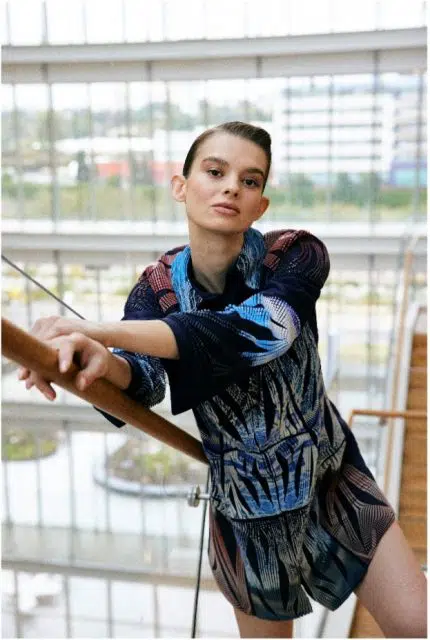

“I gravitate toward new technologies that afford me an opportunity to create something original. With Stratasys 3D fashion printing technology, the possibilities are endless. Honestly, it provides a chance to experiment, and I feel like I have only scratched the surface of what is possible,” said Karim Rashid, fashion designer and SSYS 2Y22 REFLECTION collection contributor.

A variety of materials are available for the J850 TechStyle 3D printer including Agilus30™ CMY color materials for full-color, flexible printing and the Vero™ ContactFlex, a transparent coating that can be used to create a soft touch, silky feel. Stratasys VeroVivid™ resin material allows fashion houses and designers to print on textiles in over 600,000 unique colors, with multiple shore values, simulating different textures and finishes.

The upcoming SSYS 2Y22 collection reflects the last two years of the COVID-19 pandemic and the innovation and influences of this time on fashion and design. The collection will include new works by seven top design teams, such as high-end dresses and suits, daywear, lighting, luxury packaging, handbags, accessories and shoes. The J850 TechStyle 3D printer and the SSYS 2Y22 collection will be on display at Milan Design Week from June 6 -12, 2022.

The J850 TechStyle 3D printer is available now and more information is available online.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment