3D printer manufacturer Stratasys has partnered with Siemens Healthineers to conduct a research project focused on advancing medical imaging phantoms used in computed tomography (CT) imaging proving to be a vital tool in hospitals globally.

Ensuring complete radiographic accuracy for patient-specific pathology, this partnership aims to develop phantoms that possess ultra-realistic human anatomy characteristics. This technological advancement could potentially lead to the substitution of 3D printed structures for human cadavers in certain situations. Doing so would result in enhanced efficiency and reduced human variability during testing and calibration processes.

“The current limitations of imaging phantoms have been a longstanding challenge for the radiology community,” said Erez Ben Zvi, Vice President Medical at Stratasys. “This partnership with Siemens Healthineers will enable us to jointly explore the vast possibilities of our radiopaque materials and 3D printing technologies to overcome these barriers.”

An alliance to create customized 3D phantoms with enhanced radiopacity

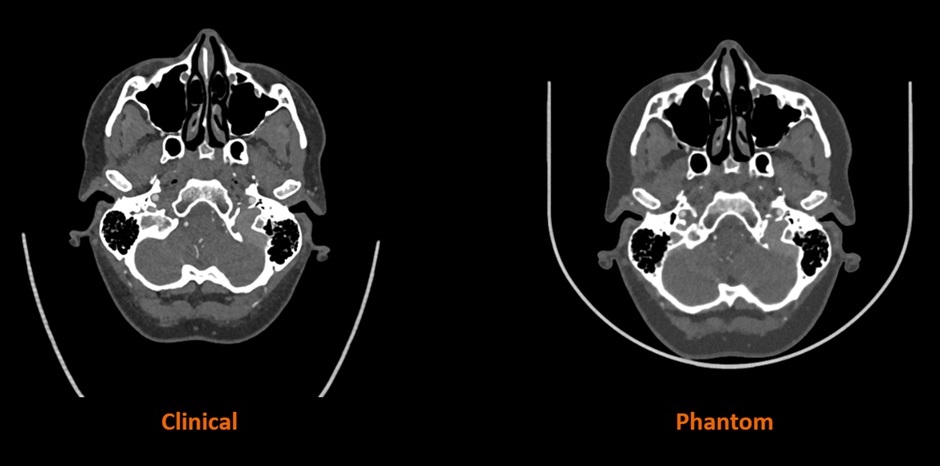

Specialized devices known as CT phantoms are employed to assess and guarantee the functionality of CT scanners by replicating distinct human body characteristics. The collaboration involves integrating Stratasys’ PolyJet technology and RadioMatrix technology with Siemens Healthineers’ advanced algorithm to improve the radiopacity of human anatomy. This integration facilitates the production of customized phantoms tailored to specific characteristics, marking a significant advancement in phantom manufacturing.

The project begins with the production of 3D printed phantoms tailored for smaller-scale anatomies in the head and neck region, consequently progressing to creating anatomies that are increasingly larger and complex. This progression culminates in Phase One, where the objective is to achieve 3D printing milestones, namely crafting a model of the heart and an entire human torso with comprehensive radiographic precision.

“Knowledge gained from this project provides a breakthrough in medical imaging that will open up new avenues for uses when it comes to 3D printing and imaging,” said Lampros Theodorakis, Head of Computed Tomography Product & Clinical Marketing at Siemens Healthineers. “We are excited about the opportunities ahead of us as a result of this partnership and believe it will have long-term impacts for medical and academic applications.”

Through a collective effort, the research is anticipated to yield a substantial body of data, contributing valuable insights for the progression of CT system algorithms, materials development, and the exploration of new application areas. Additionally, the findings may identify potential avenues for additional studies in the field of medical imaging.

Manufacturing on Demand

Stratasys’ healthcare partnerships

Stratasys and Ricoh collaborated to provide on-demand 3D printed anatomical models for clinical settings, combining Stratasys’ Patient-Specific 3D Solutions, Axial3D‘s Segmentation-as-a-Service, and Ricoh’s additive manufacturing services. This partnership democratizes access to precision additive manufacturing, allowing healthcare providers to obtain patient-specific 3D printed models for surgical planning, diagnosis, and education. The streamlined process involves cloud-based AI-powered software to convert medical scans into 3D printable files, 3D printed at Ricoh’s facility, reducing turnaround time from weeks to days without requiring on-site 3D printing equipment or expertise.

Additionally, CollPlant and Stratasys partnered to advance healthcare through large-scale bioprinting of tissues and organs. Their collaboration utilizes CollPlant’s rh-Collagen-based bioinks and Stratasys’ P3 technology bioprinter, with a primary focus on developing regenerative breast implants. By combining Stratasys’ precise P3 3D printing and CollPlant’s bioinks, the bioprinter aims to enable natural breast tissue growth without triggering immune responses, potentially transforming both cosmetic and reconstructive surgery. The collaboration includes cross-promotion, allowing customers to purchase each other’s bioprinting products, targeting the $2.6 billion market for breast augmentation and reconstruction.

You might also like:

BLT 3D printed WedoCage spinal implants gain market approval in China: The company’s Hydroxyapatite-Coated Porous Titanium Alloy Interbody Fusion Device, or WedoCage, was 3D printed using technology from Chinese 3D printer manufacturer Bright Laser Technologies (BLT).

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Ada Shaikhnag

Leave A Comment