Dental 3D printer manufacturer SprintRay has raised over $100 million in Series D funding, according to a Deal Street Asia report.

While led by the SoftBank Group’s Vision Fund 2, SprintRay’s funding round was also supported by Yiheng Capital and ZWC Partners, as well as long-term backers CD Capital and Marathon Venture Partners. Using its newfound capital, the firm reportedly plans to build out its business beyond its traditional US and European target markets to generate more sales in Southeast Asia.

“The penetration of dental 3D printing solutions is rising fast in the US, amid the evolving user behavior and consumption patterns of dentists and patients,” Michael Yao, a Partner at ZWC Partners told Deal Street Asia. “SprintRay will become a truly indispensable brand to dentists when it can create up to 60% of dental products using 3D printing in the future, versus the current 10-20%.”

SprintRay’s DLP printing portfolio

SprintRay, a subsidiary of Zhejiang Xunshi Technology or ‘SoonSolid‘, was established in 2014 with the goal of bringing a low-cost, end-to-end 3D printing platform to dental practitioners around the world. Since then, the company has set up operations in China, the US, and Europe, from which it markets a Digital Light Processing (DLP) portfolio.

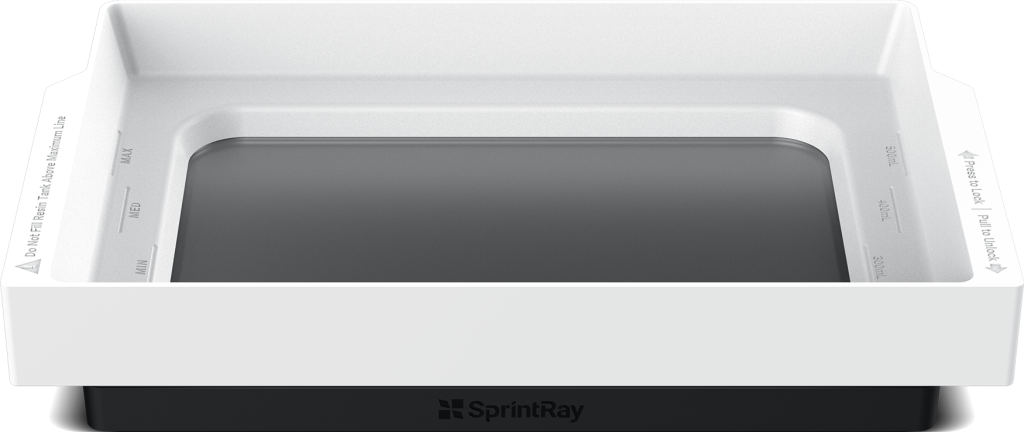

This offering primarily revolves around the SprintRay Pro S 3D printer, a system that’s built to be easy to learn, train, and delegate to staff in dental labs and practices. The machine is able to simplify adopters’ production workflows thanks to the RFID technology embedded in its resin tank, which allows it to track the progress of prints as well as many other parameters and trigger notifications to users.

In line with SprintRay’s mantra that its products are ‘simple but sophisticated,’ the unit also features an advanced chassis and all-glass construction that improve print stability and uniformity across the build platform. In tandem with its ancillary range of post-processing gear and materials, the SprintRay Pro S enables the production of dental crowns, models, guards, aligners, splints, and other dental models.

The success of its products in addressing these areas has seen the firm grow significantly during the past eight years to a team of nearly 700 people, around 35% of which are said to be R&D professionals. However, Desktop Metal got an injunction against SprintRay late last year, which has prevented it from selling the Pro S in Germany, thus its path toward growth has not been entirely smooth sailing.

Plotting a dental 3D printing expansion

Over the last five years, SprintRay has raised a significant amount of funding for the costs of running and expanding its business. Having completed angel funding rounds in 2017 and 2018, the firm secured over 100 million yuan (or around $14.1 million) in October 2019 via an investment from CD Capital and Marathon Venture Partners.

Manufacturing on Demand

This was followed by a Series C funding round completed in November 2020, which according to SprintRay, saw it raise “hundreds of millions of yuan” from the China Life Investment Fund, an equity fund backed by China Life.

While SprintRay’s fundraising efforts have already yielded investments from many Chinese firms, like the smartphone manufacturer Xiaomi founder Lei Jun-led Shunwei Capital, its latest deal is different. The SoftBank group is not only Japan-based but its Vision Fund 2 has already backed 3D printing firms via investments in Gelato’s $240 million raise and Formlabs’ $150 million funding drive.

Using the capital invested in it, SprintRay now plans to expand well past the US, which is its main market, further into Southeast Asia, as well as new areas like the Middle East, India, and Australasia. Given that the firm says its continued aim is to “revolutionize dentistry by bringing “affordable, easy, in-office manufacturing to every dental practice,” it’s also likely to shell out on product R&D moving forwards.

Competition in dental 3D printing

As additive manufacturing continues to gain ground in the dental sector, the market for 3D printers capable of addressing the industry has become increasingly competitive. Earlier this year, Desktop Health launched the Einstein, a system with a similar DLP architecture to the machines of fellow Desktop Metal firm ETEC, and extensive potential dental applications.

Dentsply Sirona has also introduced its own Google Cloud-integrated portfolio, composed of the Primeprint 3D printer and PPU. Powered by a 385nm light engine, the former is targeted similarly to the SprintRay Pro S, in that it’s designed to enable dentists to simply produce models, guides, provisionals, or splints, without sacrificing on part quality.

Elsewhere in the industry, Formlabs, which has long marketed its systems in this area, continues to take strides toward making them more accessible. In February 2022, for instance, Formlabs partnered with Medit to make its PreForm app compatible with the manufacturer’s dental 3D scanners, in a move that has since allowed dental users to streamline their workflow.

You might also like:

Rady Children’s Hospital develops free software that turns patient data into 3D printable anatomical models: Created in-house by the hospital’s Helen and Will Webster Foundation 3D Innovations (3DI) Lab, ‘Media2DICOM’ converts 3D models of patients into the DICOM files often used by physicians to share data. In doing so, the program allows medical staff to more easily access anatomical 3D reconstructions, saving them time, while helping them tailor treatment to improve childrens’ clinical outcomes.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment