SLM Solutions just demonstrated the productivity of its new 12-laser NXG XII 600 PBF system with Porsche. The Porsche advanced powertrain engineering department focuses on large powertrain applications, such as the E-drive housing and cylinder blocks or cylinder heads in additive manufacturing.

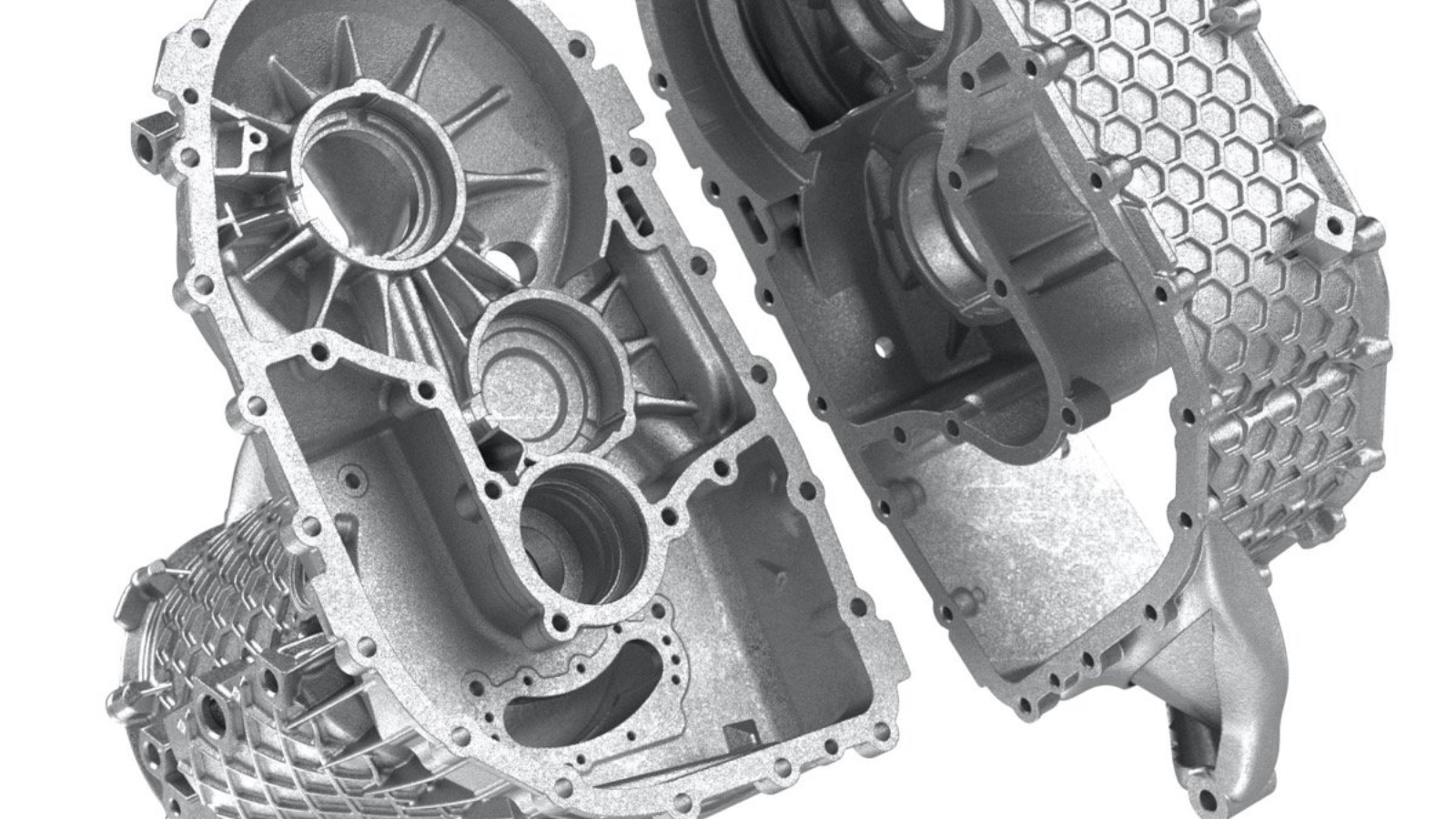

In a proof of concept with the SLM® machine NXG XII 600, a complete E-drive housing with an innovative AM Design was successfully printed. Porsche thereby set high-quality demands on the part: a permanent magnet motor with 800-volt operating voltage delivers up to 205 kW (280 hp). The downstream two-stage transmission is integrated in the same housing and drives the wheels with up to 2,100 Newton meters of torque. This highly integrated approach is designed for use on the front axle of a sports car.

Has metal 3D printing arrived in the manufacturing industry and is the technology ready to enter serial production? What does it take to make the leap to industrialization? With its recently launched SLM machine NXG XII 600, SLM Solutions used this application to provide some early answers to these questions.

Manufacturing on Demand

“This new manufacturing technology is technically and economically interesting for us,” confirmed Falk Heilfort, Powertrain Development Engineer at Porsche. “Possible use cases are especially prototypes in the development phase, special and small series production as well as for motor sport and classic spare parts.“ The E-drive unit measures 590 x 560 x 367 mm and was built in only 21 hours on the NXG XII 600.

The NXG XII 600 is equipped with twelve overlapping 1 kW lasers and a build envelope of 600x600x600 mm, enabling the production of large-volume square parts with up to 120 µm layer thickness and even more. Productivity is further enhanced through variable beam spot, bi-directional recoating, laser balance and an optimized gas flow while a closed environment maximizes operator safety.

All the advantages of additive manufacturing have been implemented in this housing such as topology optimization with lattice structures to reduce the weight, functional integration of cooling channels, higher stiffness and reduced assembly time by the integration of parts as well as improvements in part quality.

Ralf Frohwerk, Global Head of Business Development of SLM Solutions, is delighted with the excellent results of the Porsche part: “We are glad and proud to cooperate with highly innovate companies like Porsche. The NXG XII 600 achieves unmatched levels of performance and functional improvements of key automotive parts while delivering cost productivity that enables broad use of additive manufacturing technology for true series production. We are thrilled to take this big step towards full industrialization of metal additive manufacturing for Porsche applications.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment