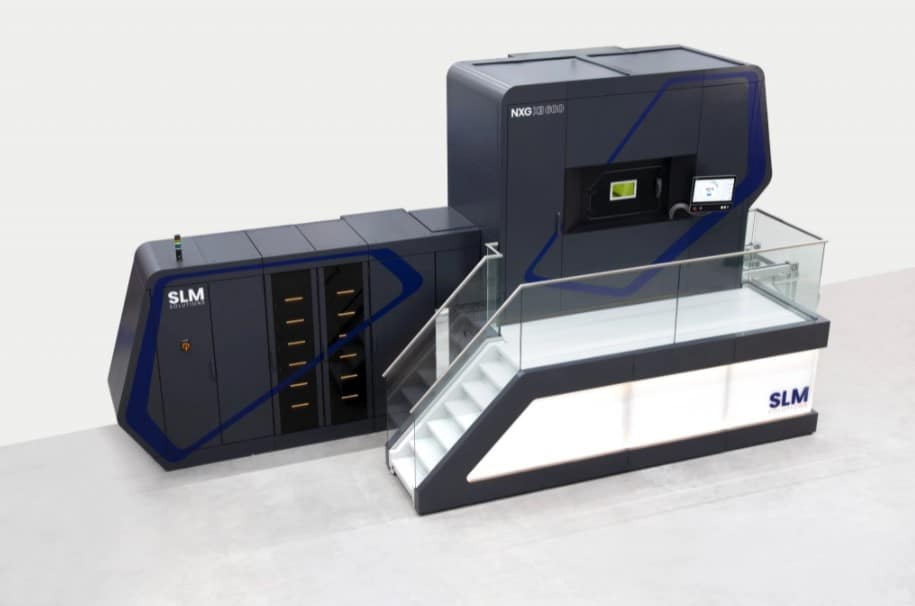

Last week SLM Solutions held a large company and customer meeting at its HQ in Lubeck to show off the final and functional version of the huge NXG XII 600 SLM 3D printer. Now Sintavia, one of the premier manufacturers of advanced propulsion and thermodynamic systems for the aerospace, defense, and space industry, has ordered two NXG XII 600s in a move that will significantly advance the entire industry.

The order will give Sintavia and its diverse customer base a competitive advantage due to the unprecedented demand for printed metal componentry. The NXG Xll 600s will enable Sintavia to cost-effectively supply that demand by manufacturing parts at a rate and quality that remains unequaled in the industry.

The efficiency and capabilities of the NXG XII 600 were tested on a benchmark part for Sintavia that proved to be one of the most challenging builds ever created using the LPBF process. The results were astounding: the benchmark part, in this case, a large Inconel shrouded impeller with an exposure area of more than 50% and a weight of 174 kg was built successfully in under a week. This will enable Sintavia to go into serial production as soon as the first machine is delivered.

“It is very clear that future flight and launch OEMs will depend on complex mechanical systems enabled by additive technology,” said Brian Neff, Sintavia’s founder, and CEO. “The sheer size and efficiency of the NXG Xll 600 platform will greatly accelerate this profound modality shift. We are looking forward to unlocking its benefits on behalf of our aerospace, defense, and space customers.”

Charlie Grace, Chief Sales Officer for SLM Solutions, commented on the partnership: “We are excited to strengthen our strategic relationship with Sintavia. With the new additions to its fleet, Sintavia can manufacture the most challenging and oversized applications for aerospace, defense, and space customers at warp speed. There is no doubt that the amazing capabilities of the NXG Xll 600, coupled with the strong market reach of Sintavia, will enable significant innovation and success.”

The NXG XII 600 is a state-of-the-art system ideal for industrial serial production of complex components. It contains twelve 1000W lasers and the industry’s largest build envelope of 600x600x600mm³, which enables the production of large-scale components that were previously unable to be made.

Author: Davide Sher

Leave A Comment